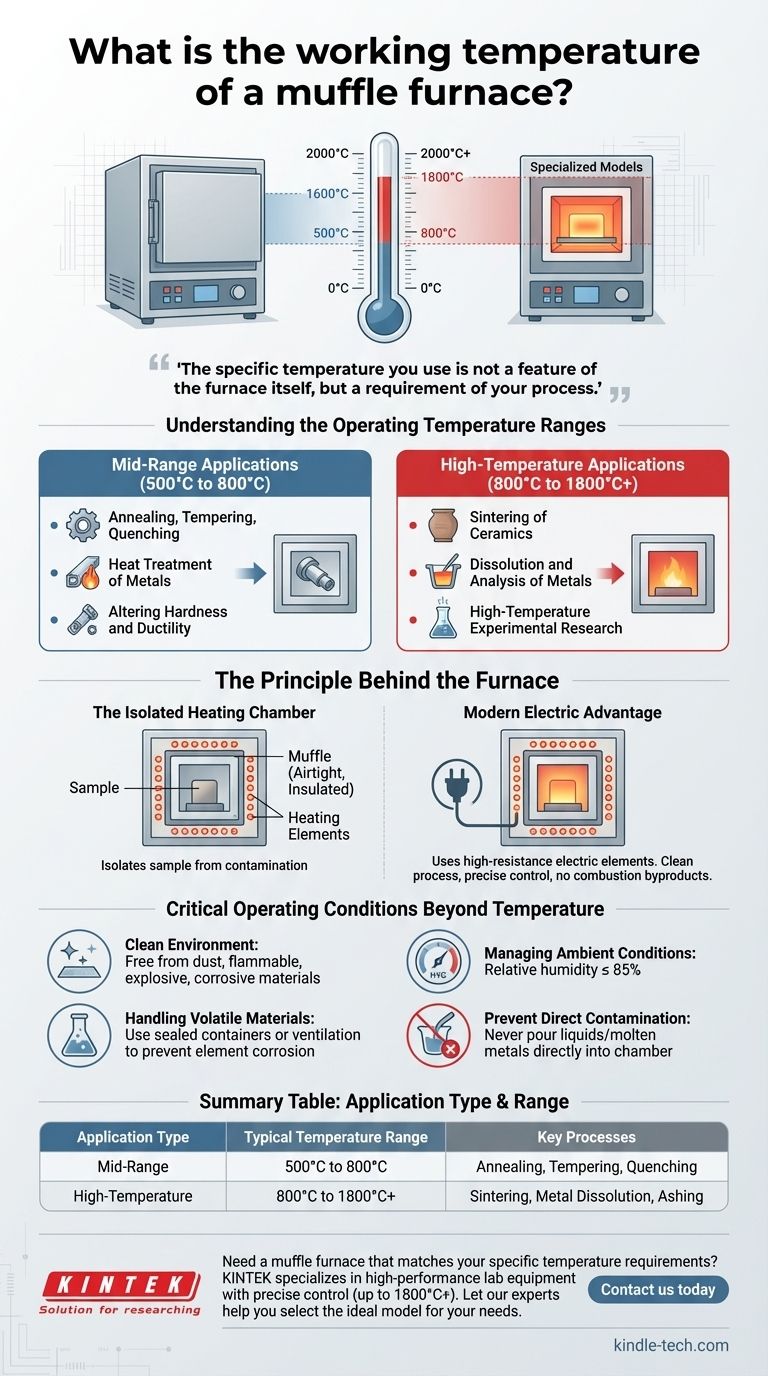

The typical working temperature of a muffle furnace is exceptionally high, generally ranging from 800°C to 1800°C (1472°F to 3272°F). Some specialized models are capable of reaching temperatures exceeding 2000°C. This wide operational range allows these furnaces to alter the physical and chemical characteristics of various materials for laboratory and industrial applications.

The specific temperature you use is not a feature of the furnace itself, but a requirement of your process. Understanding that different applications demand vastly different temperature ranges is the key to using a muffle furnace correctly and safely.

The Principle Behind the Furnace

A muffle furnace is designed for high-temperature processes that require a completely isolated and controlled environment, free from contamination.

The Isolated Heating Chamber

The defining feature of this furnace is its muffle, an insulated, airtight inner chamber where the material is placed. This design isolates the sample from the heating elements and any potential byproducts of combustion in older, fuel-fired models.

Modern Electric Advantage

Modern muffle furnaces are typically electric. They use high-resistance heating elements to heat the chamber, which eliminates combustion byproducts entirely. This ensures a clean heating process and allows for highly precise temperature control and uniformity.

Understanding the Operating Temperature Ranges

The required temperature is dictated entirely by the intended application. These can be broadly grouped into mid-range and high-temperature processes.

High-Temperature Applications (800°C to 1800°C+)

This upper range is used for processes that require significant material transformation. Common applications include the sintering of ceramics, the dissolution and analysis of metals, and other high-temperature experimental research.

Mid-Range Applications (500°C to 800°C)

The lower end of the furnace's capability is typically used for the heat treatment of metals. Processes like quenching, annealing, and tempering of small steel parts fall within this range to alter their hardness and ductility.

Critical Operating Conditions Beyond Temperature

Achieving the right temperature is only part of the process. The operating environment is equally critical for safety, accuracy, and the longevity of the furnace itself.

The Importance of a Clean Environment

The furnace should always operate in an area free from conductive dust, flammable materials, explosive substances, and corrosive gases. These can damage the equipment or create serious safety hazards at high temperatures.

Managing Ambient Conditions

The relative humidity of the operating environment should not exceed 85%. Excessive moisture can interfere with the furnace's electronic components and overall performance.

Handling Volatile Materials

When heating materials like metals or grease that may produce volatile gases, special precautions are necessary. These gases can corrode the electric heating elements, drastically reducing their service life. Use sealed containers or ensure appropriate ventilation as recommended by the manufacturer.

Preventing Direct Contamination

Never pour liquids or place molten metals directly into the furnace chamber. This can cause thermal shock and permanently damage the muffle. Always keep the chamber clean to prevent impurities from affecting your process.

Matching Temperature to Your Process

Your goal determines the correct operational parameters. Consider the nature of your work to define your approach.

- If your primary focus is material transformation (sintering, ashing): You will operate in the higher range, typically from 800°C to 1800°C, to fundamentally alter the sample's properties.

- If your primary focus is metal heat treatment (annealing, tempering): Your target temperature will be in the moderate range, generally between 500°C and 800°C, to modify metallurgical characteristics without melting.

- If your primary focus is safety and equipment longevity: You must prioritize a clean, controlled operating environment and proper sample containment, as these factors are just as crucial as the temperature setting.

Mastering a muffle furnace means understanding it as a complete system, where temperature, environment, and procedure work together to produce reliable results.

Summary Table:

| Application Type | Typical Temperature Range | Key Processes |

|---|---|---|

| High-Temperature | 800°C to 1800°C+ | Sintering, Metal Dissolution, Ashing |

| Mid-Range | 500°C to 800°C | Annealing, Tempering, Quenching of Metals |

Need a muffle furnace that matches your specific temperature requirements? KINTEK specializes in high-performance lab equipment, offering furnaces with precise temperature control (up to 1800°C+), uniform heating, and contamination-free chambers—perfect for sintering, ashing, or metal treatment. Let our experts help you select the ideal model for your laboratory's needs. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is the difference between a muffle furnace and a drying oven? Choose the Right Thermal Tool

- What is the difference between an oven and a muffle? Choose the Right Heating Tool for Your Lab

- What 5 safety precautions should be taken when heating anything in the lab? Essential Rules for Lab Safety

- What PPE is required for a muffle furnace? Essential Gear for High-Temperature Safety