At a minimum, you must wear high-temperature resistant gloves, safety glasses or goggles, a lab coat, long pants, and closed-toe shoes when operating a muffle furnace. The most critical piece of equipment is the thermal gloves, which protect you from severe burns when loading or unloading samples.

The core principle of muffle furnace safety is understanding that PPE is your last line of defense against extreme heat. While gloves and glasses are non-negotiable, true safety comes from combining the right gear with safe operating procedures and an awareness of the furnace's engineering controls.

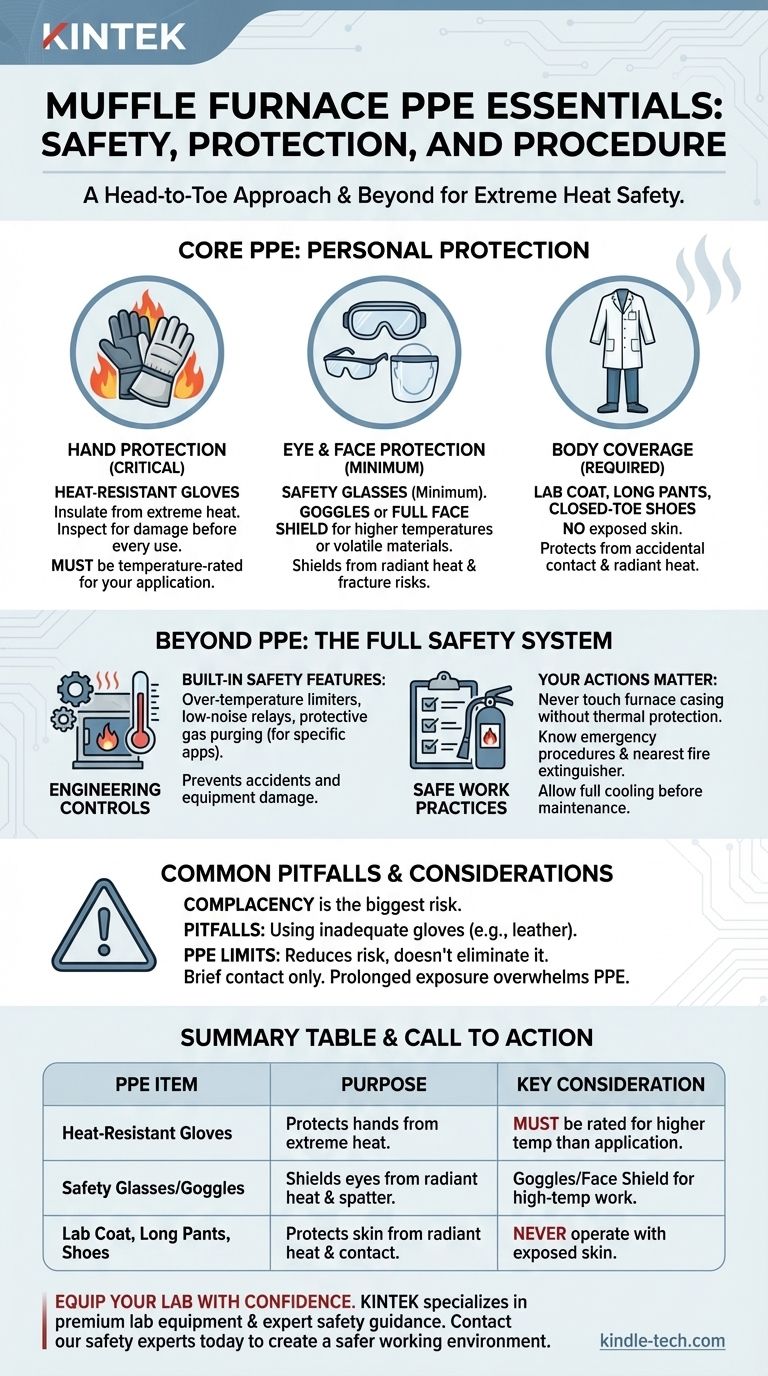

Core PPE for Muffle Furnace Operation

Proper protection involves a head-to-toe approach, focusing on shielding your skin and eyes from both direct contact and radiant heat.

Primary Hand Protection (Heat-Resistant Gloves)

Your hands are most at risk when interacting with the furnace. High-temperature or thermal gloves are the most critical piece of PPE.

These gloves are specifically designed to insulate you from the extreme heat of the furnace chamber and the samples within. Always wear them when opening the door, loading specimens, or removing items.

Before each use, inspect your gloves for any rips, holes, or tears, as any damage can compromise their protective barrier.

Essential Eye and Face Protection

You must protect your eyes from intense radiant heat and any potential for materials to fracture or pop at high temperatures. Safety glasses are the minimum requirement.

For higher temperature applications or when working with volatile materials, goggles or a full face shield provide a more complete barrier.

Protective Body Coverage

Never operate a muffle furnace with exposed skin on your arms or legs. A lab coat, long pants, and closed-toe shoes are required.

This combination protects your body from accidental contact with hot surfaces and shields your skin from the significant radiant heat the furnace emits during operation.

Beyond PPE: Understanding the Full Safety System

Relying on PPE alone is insufficient. A safe process integrates personal equipment with the furnace's own safety features and your established procedures.

Built-in Engineering Controls

Modern muffle furnaces include features designed to prevent accidents. These often include an over-temperature limiter that automatically shuts down the furnace to protect both the equipment and its load.

They may also feature low-noise solid-state relays and connections for purging with non-flammable protective gases, which are critical safety controls for specific applications.

Safe Work Practices

Your actions are a key part of the safety system. Never touch the furnace casing without proper thermal protection, as the exterior surfaces can become extremely hot.

Always be aware of emergency procedures and know the location of the nearest fire extinguisher. Allow the furnace to cool down completely before performing any maintenance.

Common Pitfalls and Considerations

Avoiding common mistakes is just as important as wearing the right gear. Complacency is the biggest risk when working with high-temperature equipment.

Not All Gloves Are Equal

The most common mistake is using gloves that are not rated for the furnace's operating temperature. A standard leather glove offers no protection.

Always verify that your thermal gloves are rated to a temperature higher than your specific application requires.

The Limits of Personal Equipment

PPE reduces the risk of injury; it does not eliminate it. It is designed to protect you from brief, accidental contact.

Prolonged exposure to the furnace's heat will overwhelm any glove or lab coat. Maintain a safe distance whenever possible and work efficiently when interacting with the furnace.

Making the Right Choice for Your Goal

Select your PPE based on the specific temperatures and procedures you are using.

- If your primary focus is routine, lower-temperature work (below 500°C): Your standard kit of rated thermal gloves, safety glasses, a lab coat, long pants, and closed-toe shoes is sufficient.

- If your primary focus is high-temperature applications (above 500°C): You must verify your gloves have a high enough temperature rating and consider using safety goggles or a face shield for superior protection.

- If your primary focus is long-duration or frequent use: Emphasize rigorous pre-use inspection of all PPE and cultivate a disciplined habit of following safe work practices without fail.

Ultimately, a safe working environment is achieved by treating the muffle furnace with respect and layering your protection through engineering controls, safe procedures, and the correct PPE.

Summary Table:

| PPE Item | Purpose | Key Consideration |

|---|---|---|

| Heat-Resistant Gloves | Protects hands from extreme heat when loading/unloading. | Must be rated for temperatures higher than your application. |

| Safety Glasses/Goggles | Shields eyes from radiant heat and material spatter. | Goggles or face shield recommended for high-temp work. |

| Lab Coat, Long Pants, Closed-Toe Shoes | Protects skin from radiant heat and accidental contact. | Never operate with exposed skin on arms or legs. |

Equip your lab with confidence and ensure complete operator safety. Proper PPE is just one part of a safe high-temperature workflow. KINTEK specializes in premium lab equipment, including muffle furnaces with advanced safety features, and can provide expert guidance on the right safety protocols for your specific application. Contact our safety experts today to discuss your laboratory's needs and how we can help you create a safer working environment.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What function does a muffle furnace serve in Mg-doped NASICON powder preparation? Master Solid-State Synthesis

- What role does a high-temperature muffle furnace play in biomass torrefaction? Optimize Your Solid Fuel Research

- What roles do the two-step sintering processes play in high-temperature furnaces? Mastering High-Density Magnesia.

- What is a lab drying oven used for? Master Moisture Removal & Sterilization for Your Lab

- How does a laboratory high-temperature furnace influence adsorbents in SGC? Optimize Your Adsorbent Synthesis

- What is the necessity of using a high-temperature box furnace for the 300°C heat treatment? Curing & Adhesion Experts

- Why is precise temperature control of a muffle furnace necessary for beta-Fe2O3? Master Metastable Nanostructure Purity

- What is the method of determining ash? Choose the Right Ashing Method for Your Lab