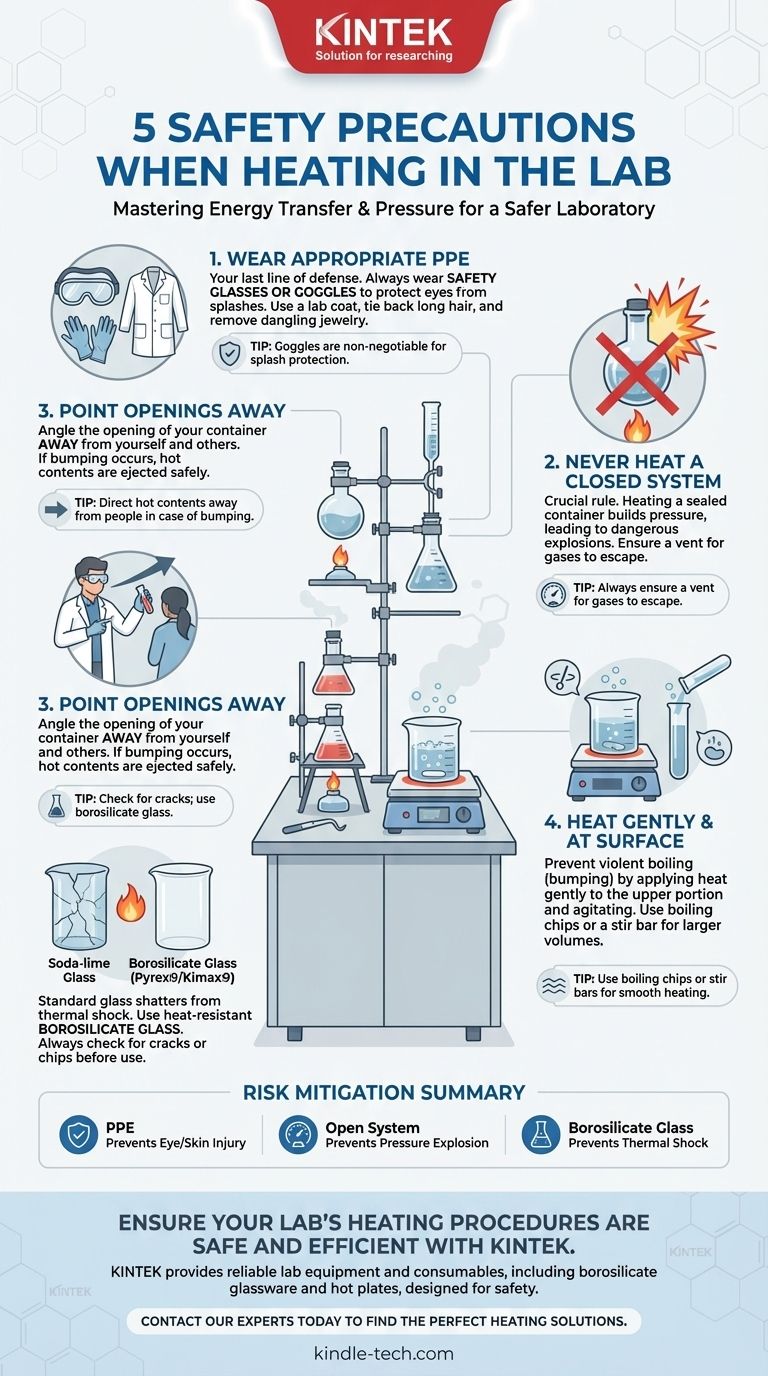

In the laboratory, heating a substance is one of the most common yet hazardous procedures you can perform. The five most critical safety precautions are to always wear appropriate personal protective equipment (PPE), never heat a closed container, always direct the opening of your container away from people, heat the liquid gently near its surface to prevent violent boiling, and ensure you are using heat-appropriate glassware like borosilicate glass. Following these rules is not about ticking boxes; it's about fundamentally controlling energy and pressure to prevent accidents.

The core principle of safe heating is managing energy transfer to prevent a sudden, uncontrolled release. Every precaution, from angling a test tube to choosing a hot plate over a flame, is a strategy to avoid violent splashes, pressure explosions, or fires.

The Foundation: Personal and Environmental Safety

Before you even apply heat, you must prepare yourself and your workspace. Most heating accidents are preventable, and prevention begins with what you wear and where you work.

Always Wear Appropriate PPE

Personal Protective Equipment is your last line of defense. Safety glasses or goggles are non-negotiable, as they protect your eyes from splashes that can occur in a fraction of a second.

A lab coat protects your skin and clothing, while tying back long hair and removing dangling jewelry prevents contact with open flames or hot surfaces.

Maintain a Stable and Clear Workspace

Your heating apparatus should be set up on a flat, stable surface away from the edge of the bench. Ensure there is no clutter around it.

Crucially, never reach over an open flame or hot plate. Always maintain a clear path so you can move away quickly if a problem arises.

The Physics of Safe Heating: Managing Pressure and Bumping

Heating a liquid introduces energy, causing it to expand and turn into gas. If not managed correctly, this rapid phase change can lead to dangerous consequences.

Never Heat a Closed System

This is arguably the most important rule. Heating a substance in a completely sealed container causes internal pressure to build up dramatically.

The result is not a simple crack; it is an explosion that propels glass shards and hot, often corrosive, chemicals across the lab. Always ensure there is a vent for gases to escape.

Point Openings Away From Everyone

When heating a liquid in a test tube or flask, always angle the opening away from yourself and anyone else nearby. This is a simple but critical habit.

If the liquid suddenly boils over or "bumps," this orientation ensures the hot contents are ejected into a safe, unoccupied area of the lab, not into someone's face.

Heat Gently and Near the Surface

Sudden, violent boiling, known as bumping, occurs when the bottom of a liquid becomes superheated but cannot form bubbles. When a bubble finally does form, it does so with explosive force.

To prevent this, apply heat gently to the upper portion of the liquid while gently agitating the container. This creates a smoother temperature gradient and allows for controlled boiling from the top down. For boiling larger volumes, using boiling chips or a magnetic stir bar is standard practice to promote even heat distribution.

Common Pitfalls and Equipment Choices

Choosing the wrong tool or material for the job can undermine all other precautions. Understanding the limitations of your equipment is as important as the procedure itself.

Bunsen Burner vs. Hot Plate

An open flame is a powerful but dangerous heat source. Never use a Bunsen burner to heat flammable or volatile organic solvents. The vapors can easily ignite, causing a flash fire.

A hot plate is the safer choice for flammable materials. It provides more controlled, even heating without an open flame. Always use a hot plate in a well-ventilated fume hood when working with volatile substances.

Using the Correct Glassware

Not all glass is created equal. Standard glassware (like a drinking glass) is typically made of soda-lime glass, which will crack or shatter when exposed to rapid temperature changes, a phenomenon called thermal shock.

Laboratory glassware intended for heating, such as Pyrex® or Kimax®, is made of borosilicate glass. This material has a much lower coefficient of thermal expansion, making it highly resistant to the stress of rapid heating and cooling. Always check your glassware for cracks or chips before use, as these create weak points.

Making the Right Choice for Your Task

Your specific procedure will determine how you apply these principles.

- If you are heating a small sample in a test tube: Focus on angling the tube correctly, heating near the surface, and never pointing it at anyone.

- If you are boiling a larger volume in a flask: Use a hot plate with a stir bar or add boiling chips to ensure smooth, even boiling and prevent bumping.

- If you are working with a flammable solvent: Use a hot plate inside a fume hood and ensure there are no open flames anywhere in the vicinity.

Ultimately, laboratory safety is a deliberate practice, not just a checklist to be memorized.

Summary Table:

| Precaution | Key Action | Primary Risk Mitigated |

|---|---|---|

| Wear Appropriate PPE | Safety glasses/goggles, lab coat | Eye/skin injury from splashes |

| Never Heat a Closed System | Ensure a vent for gas escape | Pressure explosion |

| Point Openings Away | Angle container away from people | Projectile injury from bumping |

| Heat Gently and at Surface | Apply gentle heat, agitate container | Violent boiling (bumping) |

| Use Correct Glassware/Equipment | Use borosilicate glass, hot plates for flammables | Thermal shock, fires |

Ensure your lab's heating procedures are safe and efficient with the right equipment from KINTEK.

Heating substances is a fundamental but hazardous lab procedure. Using the correct, high-quality equipment is a core part of a robust safety protocol. KINTEK specializes in providing reliable lab equipment and consumables—including borosilicate glassware, hot plates, and heating mantles—designed to withstand the demands of your applications while prioritizing user safety.

Let us help you build a safer lab. Contact our experts today to find the perfect heating solutions for your specific needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the lab safety rules for heating substances? Essential Protocols to Prevent Accidents

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing

- What is the precaution for muffle furnace? Essential Safety Protocols for Lab Excellence

- What is the construction of a muffle furnace? A Deep Dive into Its Core Systems