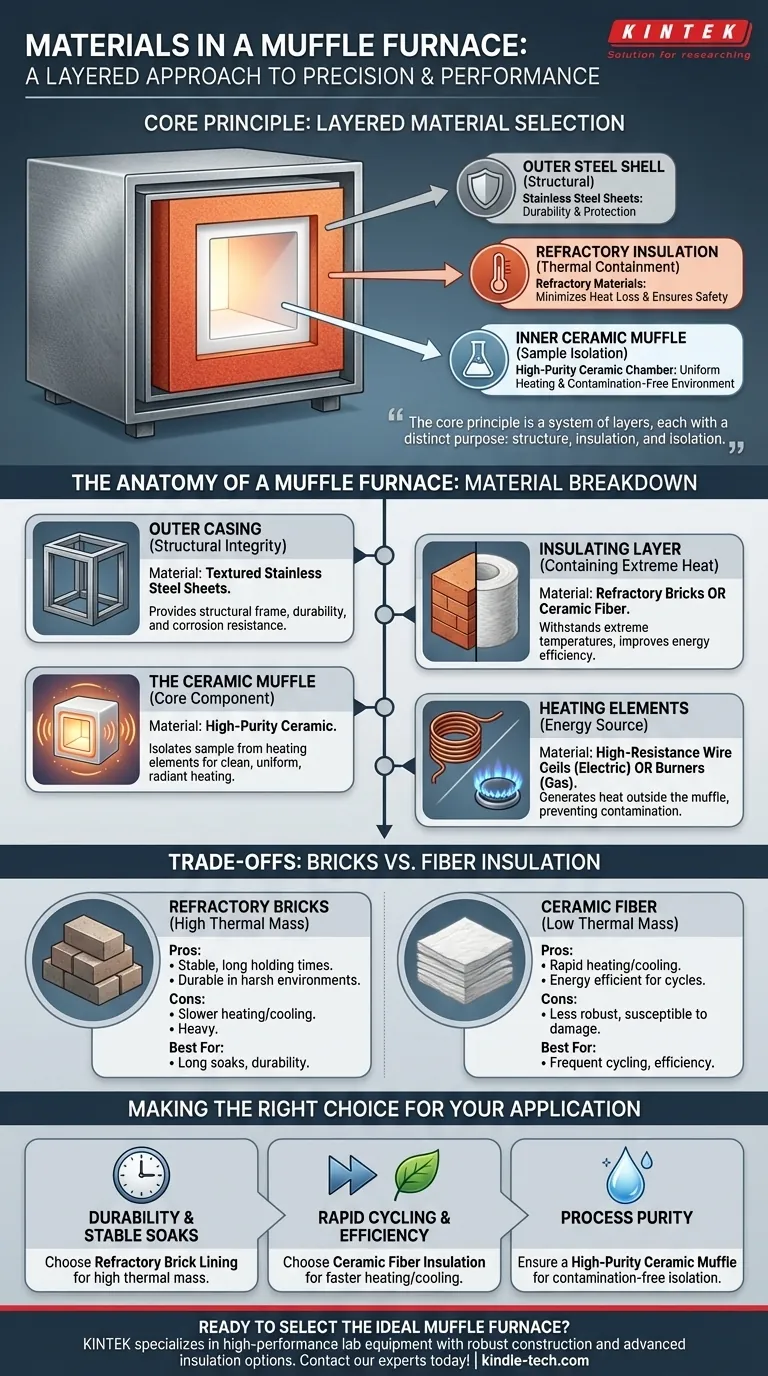

The primary materials used to construct a muffle furnace are a combination of metals and specialized ceramics. The outer body is typically made of stainless steel for structural support, while the internal chamber and insulation consist of refractory materials like ceramic bricks, ceramic fiber, and a dedicated ceramic muffle.

The core principle of a muffle furnace's construction is layered material selection. Each material serves a distinct purpose: an outer steel shell for structure, dense refractory insulation to contain extreme heat, and an inner ceramic muffle to isolate the sample and ensure a clean, uniform heating environment.

The Anatomy of a Muffle Furnace: A Material-by-Material Breakdown

Understanding why specific materials are chosen reveals how a muffle furnace achieves high temperatures while maintaining precise control and safety. The construction is a system of layers, each with a critical role.

The Outer Casing: Structural Integrity

The housing of a muffle furnace is almost always constructed from textured stainless steel sheets.

This material provides the necessary structural frame for the furnace. Its primary benefits are durability, corrosion resistance, and the ability to protect the internal components from the external environment.

The Insulating Layer: Containing Extreme Heat

Between the outer casing and the inner chamber lies a thick layer of insulation. This layer is made from refractory materials, which are designed to withstand extreme temperatures without degrading.

The two most common types are:

- Refractory Bricks: These are dense, hard bricks with high thermal mass, capable of withstanding very high temperatures (up to 1800°C in some models).

- Ceramic Fiber: This is a lightweight, fibrous insulation material. It has a lower thermal mass than brick, offering different performance characteristics.

This insulation is critical for minimizing heat loss, improving energy efficiency, and keeping the outer surface of the furnace at a safe temperature.

The Core Component: The Ceramic Muffle

The defining feature of the furnace is the muffle itself—an enclosed chamber typically made of a high-purity ceramic.

This chamber's sole purpose is to isolate the material being processed from the heating elements. By creating a barrier, the muffle prevents direct contact and contamination from fuel byproducts (in gas models) or from the elements themselves (in electric models). This ensures uniform, radiant heating and a clean processing atmosphere.

The Heating Elements: The Source of Energy

While not a structural material, the heating elements are what generate the heat. These are located outside the ceramic muffle.

In electric furnaces, these are typically high-resistance wire coils. In combustion models, they are burners for natural gas or propane. The muffle's design ensures the energy from these sources heats the chamber without contaminating what's inside.

Understanding the Trade-offs: Bricks vs. Fiber Insulation

The choice between refractory brick and ceramic fiber insulation is not arbitrary; it represents a key performance trade-off.

The Case for Refractory Bricks

Furnaces lined with refractory bricks have a high thermal mass. They take longer to heat up and cool down.

This makes them ideal for processes that require long, stable holding times at a set temperature. Their density and durability also lend themselves to harsh industrial environments.

The Case for Ceramic Fiber

Furnaces insulated with ceramic fiber are lightweight and have a low thermal mass. They heat up and cool down much more quickly.

This results in better energy efficiency for processes requiring frequent cycles. However, fiber may be less robust than brick and can be more susceptible to mechanical damage or degradation in certain chemical atmospheres.

Making the Right Choice for Your Application

Understanding these materials allows you to select a furnace that aligns directly with your process goals, whether for metallurgy, ceramics, or lab research.

- If your primary focus is durability and long, stable soaks: A furnace with a dense refractory brick lining is superior due to its thermal mass and robustness.

- If your primary focus is rapid cycling and energy efficiency: A furnace insulated with ceramic fiber offers faster heating and cooling times, which is ideal for high-throughput labs.

- If your primary focus is process purity for sensitive materials: The critical feature is a high-purity, non-reactive ceramic muffle that guarantees isolation from all contaminants.

By understanding how these materials work together, you can ensure your thermal processing is both effective and precisely controlled.

Summary Table:

| Material | Location | Primary Function |

|---|---|---|

| Stainless Steel | Outer Casing | Structural integrity, durability, and corrosion resistance. |

| Refractory Bricks | Insulation Layer | High thermal mass for stable, long soaks; high durability. |

| Ceramic Fiber | Insulation Layer | Low thermal mass for rapid heating/cooling and energy efficiency. |

| High-Purity Ceramic | Muffle Chamber | Isolates samples for contamination-free, uniform heating. |

Ready to select the ideal muffle furnace for your lab's specific thermal processing needs?

KINTEK specializes in high-performance lab equipment, including muffle furnaces with robust stainless steel construction and advanced insulation options. Whether your priority is the durability of refractory bricks for long soaks or the rapid cycling of ceramic fiber for efficiency, we have the right solution to ensure precise temperature control and sample purity.

Contact our experts today to discuss your application and find the perfect furnace to enhance your lab's productivity and results.

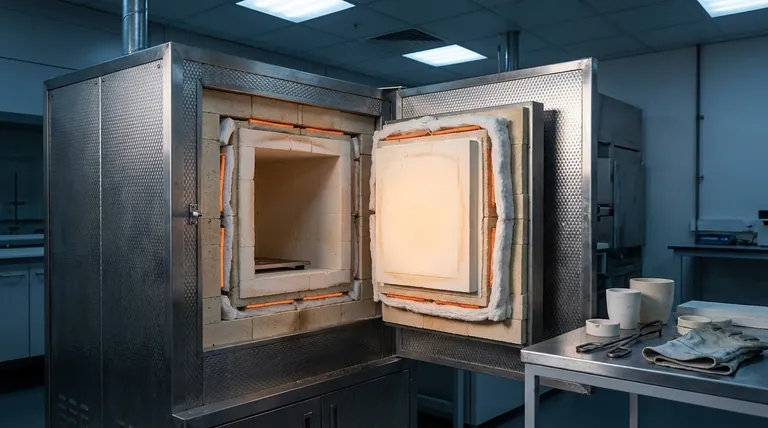

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is a high-temperature muffle furnace utilized in the performance evaluation of CrSi coatings?

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement

- What is the final stage of sintering? Master the Final Pore Elimination for Maximum Density

- What are the disadvantages of wet ashing? Key Safety & Contamination Risks

- What are the advantages of sintered materials? Achieve High-Performance, Custom Material Properties

- How do you determine the ash content of a food sample? Choose the Right Method for Accurate Mineral Analysis

- What role does a high-temperature air furnace play in HTL corrosion experiments? Ensure Data Integrity via Pre-Oxidation

- Why is an industrial muffle or tube furnace required for CeTe synthesis? Precision Thermal Management for Rare Earths