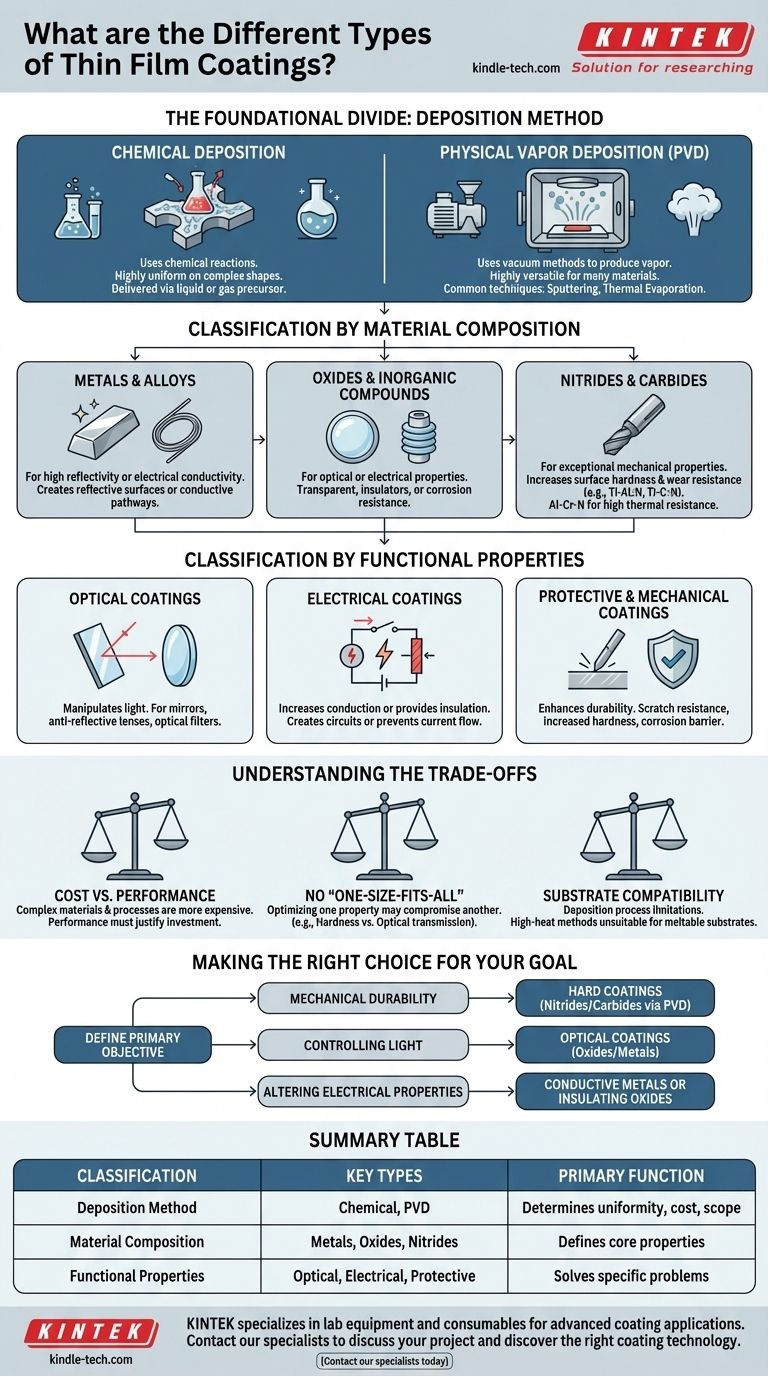

At the highest level, thin film coatings are categorized into two fundamental types based on their application method: Chemical Deposition and Physical Vapor Deposition (PVD). From there, they are further classified by their material composition—such as metals, oxides, or nitrides—and by their intended functional properties, like optical transmission or mechanical hardness.

The "type" of a thin film coating is not a single label. It is a combination of its application method, its material composition, and the specific problem it is engineered to solve, from enhancing durability to controlling electricity or light.

The Foundational Divide: Deposition Method

The most critical distinction in thin film technology is how the coating is applied to the substrate material. This choice dictates the properties, cost, and potential applications of the final product.

Chemical Deposition

Chemical deposition processes use chemical reactions at the substrate's surface to form the film. The constituent materials are delivered via a liquid or gas precursor.

This method is valued for its ability to produce highly uniform coatings over complex shapes.

Physical Vapor Deposition (PVD)

Physical Vapor Deposition encompasses a set of vacuum deposition methods that use physical processes to produce a vapor of material. This vapor then condenses on the substrate to form the thin film.

Common PVD techniques include sputtering and thermal evaporation. This approach is highly versatile for depositing a vast range of materials.

Classification by Material Composition

The material used in the coating is what defines its core characteristics. Different materials are chosen to achieve specific performance goals.

Metals and Alloys

Pure metals and their alloys are commonly used for applications requiring high reflectivity or electrical conductivity. They can be used to create reflective surfaces or conductive pathways on insulating substrates.

Oxides and Inorganic Compounds

Materials like metallic oxides are often used for their unique optical or electrical properties. They can be engineered to be transparent, act as electrical insulators, or provide robust corrosion resistance.

Nitrides and Carbides

This class of advanced materials is known for exceptional mechanical properties. Formulations like Titanium Aluminum Nitride (Ti-Al-N) and Titanium Carbonitride (Ti-C-N) are used to dramatically increase surface hardness and wear resistance on cutting tools and components.

For example, Aluminum Chromium Nitride (Al-Cr-N) is specifically valued for its high thermal resistance, which improves tool life in high-temperature cutting operations.

Classification by Functional Properties

Ultimately, thin films are chosen for what they do. This functional classification often drives the selection of both the material and the deposition method.

Optical Coatings

These films are designed to manipulate light. They are used to create highly reflective surfaces for mirrors, anti-reflective coatings for lenses, and precise optical filters that transmit or block specific wavelengths.

Electrical Coatings

Electrical coatings serve one of two purposes: increasing conduction or providing insulation. A thin layer of metal can create a circuit, while a layer of a ceramic oxide can prevent electrical current from passing through.

Protective & Mechanical Coatings

These coatings exist to enhance the durability of the underlying material. They provide crucial benefits like scratch resistance, increased hardness, and a barrier against corrosion, extending the life and performance of the substrate.

Understanding the Trade-offs

Selecting a thin film coating is a process of balancing competing requirements. There is no single "best" type of coating, only the most appropriate one for a specific application.

Cost vs. Performance

More complex, high-performance materials like Ti-Al-N and the processes required to deposit them are inherently more expensive. The desired performance gain must justify the investment.

No "One-Size-Fits-All" Solution

A coating optimized for one property often compromises another. A film designed for extreme hardness and wear resistance is unlikely to also possess the properties needed for a high-transmission optical lens.

Substrate Compatibility

The deposition process itself can be a limitation. High-temperature chemical deposition methods, for example, cannot be used on substrates that would melt or deform under that heat, forcing the selection of an alternative process.

Making the Right Choice for Your Goal

To select the correct coating, you must first define your primary objective.

- If your primary focus is mechanical durability: You should investigate hard coatings made from nitrides and carbides, such as Ti-Al-N or Al-Cr-N, applied via PVD.

- If your primary focus is controlling light: Your solution lies in optical coatings, which use precise layers of oxides and metals to achieve specific reflective or transmissive properties.

- If your primary focus is altering electrical properties: You will need to choose between conductive metals to create pathways or insulating inorganic compounds to create barriers.

Choosing the right thin film is about matching a specific material and deposition process to your unique performance requirements.

Summary Table:

| Classification | Key Types | Primary Function |

|---|---|---|

| Deposition Method | Chemical Deposition, Physical Vapor Deposition (PVD) | Determines coating uniformity, cost, and application scope |

| Material Composition | Metals/Alloys, Oxides, Nitrides/Carbides | Defines core properties like conductivity, hardness, or optical traits |

| Functional Properties | Optical, Electrical, Protective/Mechanical | Solves specific problems (e.g., light control, wear resistance, insulation) |

Need a thin film coating solution tailored to your specific requirements?

KINTEK specializes in lab equipment and consumables for advanced coating applications. Whether you're developing optical components, enhancing tool durability with hard coatings like Ti-Al-N, or require precise electrical properties, our expertise and products can help you achieve superior results.

Contact our specialists today to discuss your project and discover the right coating technology for your needs!

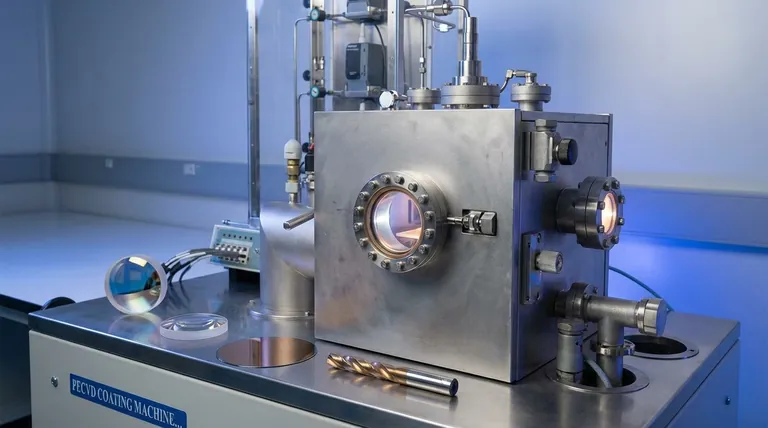

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the processes of vapor phase deposition? Understand CVD vs. PVD for Superior Thin Films

- What is the mechanism of graphene growth in CVD? A Guide to the Surface-Catalyzed Process

- What is chemical Vapour deposition method for thin film deposition? A Guide to High-Purity Coatings

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why is a substrate stage cooling system critical in high-power density plasma CVD? Master Extreme Thermal Management

- What are the methods of carbon nanotube purification? Achieve High-Purity CNTs for Your Application

- What is the pressure of sputtering process? Mastering the Key to High-Quality Thin Films

- How does process temperature influence film deposition and what are its limitations? Balancing Quality and Heat Constraints