In short, the primary disadvantage of air quenching is its slow cooling rate. This fundamental limitation means it can only harden a narrow range of specialized "air-hardening" steels and is ineffective for the vast majority of common carbon and low-alloy steels.

Air quenching sacrifices hardening power for safety. Its core drawback is that this gentle cooling process is too slow to harden anything but high-alloy steels, often resulting in lower strength and hardness even in suitable materials.

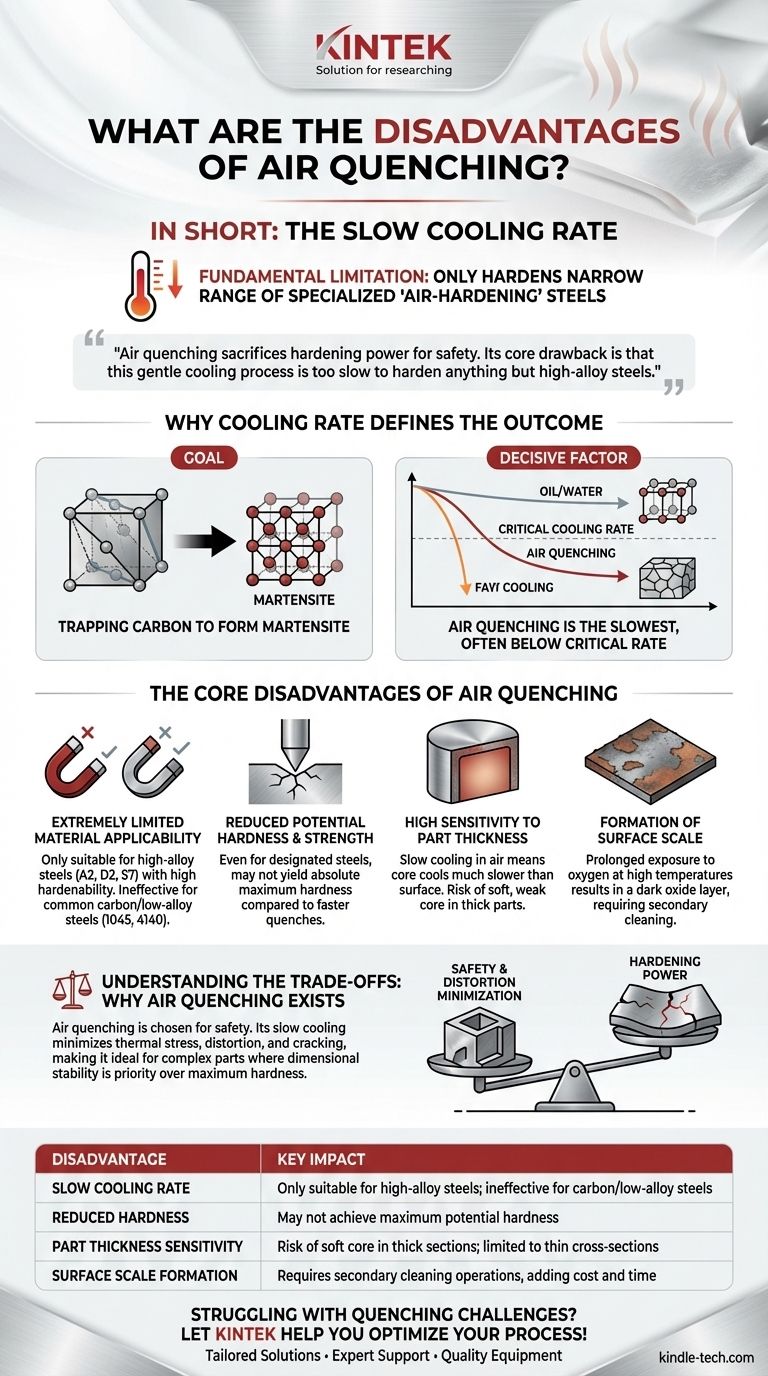

Why Cooling Rate Defines the Outcome

To understand the disadvantages fatores de um processo de têmpera, we must first understand its goal. Quenching is not just about cooling metal; it's about cooling it rapidly enough to achieve a specific metallurgical transformation.

The Goal: Locking in Hardness with Martensite

When you heat steel to its austenitizing temperature, its internal crystal structure changes. The goal of quenching is to "freeze" this structure by cooling it so quickly that the carbon atoms are trapped, forming a very hard, brittle microstructure called martensite.

The Decisive Factor: Critical Cooling Rate

Every type of steel has a Critical Cooling Rate. This is the minimum speed at which it must be cooled to form martensite and avoid softer structures like pearlite or bainite. If the cooling is too slow, the steel will not achieve its maximum potential hardness.

Where Air Quenching Fits

Air is a poor conductor of heat compared to liquids. As a result, air quenching provides the slowest cooling rate of all common quenching methods (slower than oil, water, or brine). This is the root cause of its disadvantages.

The Core Disadvantages of Air Quencing

The slow cooling rate ciência-based disadvantages of air quenching are not opinions, but direct consequences of the physics of heat transfer.

1. Extremely Limited Material Applicability

This is the most significant drawback. Air quenching is only fast enough to exceed the critical cooling rate of steels with very high hardenability.

These are typically high-alloy tool steels (like A2, D2, or S7) and some stainless steels. The alloying elements (chromium, molybdenum, vanadium) dramatically slow down the formation of soft structures, making it easy to form martensite even with a slow quench. For common and less expensive steels like 1045 or 4140, air quenching is far too slow and will result in a soft, unhardened part.

2. Reduced Potential Hardness and Strength

Even for a designated air-hardening steel, air quenching may not yield the absolute maximum possible hardness. A slightly faster quench, such as an interrupted oil quench, can sometimes produce a finer martensitic structure, leading to modest improvements in hardness and wear resistance.

3. High Sensitivity to Part Thickness (Section Size)

Heat must travel from the core of a part to its surface to dissipate. With a slow medium like air, the core of a thick part cools significantly slower than its surface.

This can create a dangerous situation where the surface is fully hardened, but the core remains soft and weak. For this reason, air quenching is generally restricted to parts with relatively thin cross-sections.

4. Formation of Surface Scale

Unless performed in a controlled vacuum or inert atmosphere furnace, the slow cooling process exposes the hot steel to oxygen for a prolonged period. This results in the formation of a dark, flaky oxide layer known as scale.

This scale must be removed in a secondary operation like media blasting or acid pickling, which adds cost, time, and results in a small amount of material loss.

Understanding the Trade-offs: Why Air Quenching Exists

Given these disadvantages, air quenching is used for one overriding reason: safety. Its slow, gentle cooling imposes minimal thermal stress on a part.

The Problem with Faster Quenches

Rapid quenching in water or oil creates extreme temperature gradients within the material. The surface cools and contracts instantly while the core is still hot and expanded. This internal stress can cause a part to warp, distort, or even crack.

Balancing Hardness and Integrity

Air quenching minimizes this risk, making it the preferred method for geometrically complex parts, dies with sharp internal corners, or high-precision components where dimensional stability is more important than achieving the absolute highest possible hardness. It is a trade-off between hardening power and the risk of part failure.

Making the Right Choice for Your Goal

Selecting a quenching method requires matching the process to both the material and the desired outcome.

- If your primary focus is maximum hardness in plain carbon or low-alloy steel: Air quenching is entirely unsuitable; a faster medium like oil, water, or brine is required.

- If your primary focus is minimizing distortion in a complex part made of a high-alloy tool steel (e.g., A2, D2): Air quenching is the ideal choice, as its low risk of cracking outweighs its other limitations.

- If you are working with thick cross-sections (e.g., over 2 inches): Air quenching is likely to result in an unhardened core and should be avoided in favor of a faster quench on an oil-hardening or water-hardening steel.

Ultimately, you should view air quenching as a specialized tool, chosen deliberately when the overriding priority is to protect a valuable and complex part from distortion and cracking.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Slow Cooling Rate | Only suitable for high-alloy steels; ineffective for carbon/low-alloy steels |

| Reduced Hardness | May not achieve maximum potential hardness even in suitable materials |

| Part Thickness Sensitivity | Risk of soft core in thick sections; limited to thin cross-sections |

| Surface Scale Formation | Requires secondary cleaning operations, adding cost and time |

Struggling with Quenching Challenges? Let KINTEK Help You Optimize Your Process!

Choosing the right heat treatment method is critical for achieving the desired balance of hardness, strength, and dimensional stability in your components. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific metallurgical needs. Whether you're working with high-alloy tool steels requiring precise air quenching or need faster quenching solutions for carbon steels, our expertise ensures you get the results you need without compromising part integrity.

Why Partner with KINTEK?

- Tailored Solutions: We help you select the right equipment and methods for your specific materials and applications.

- Expert Support: Our team provides insights to optimize your quenching process, minimizing distortion while maximizing performance.

- Quality Equipment: From furnaces to quenching media, KINTEK delivers reliable tools for consistent, high-quality results.

Ready to Enhance Your Heat Treatment Process? Contact us today to discuss your requirements and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vertical Laboratory Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process

- Why nitrogen is used in annealing furnace? To prevent oxidation and decarburization for superior metal quality