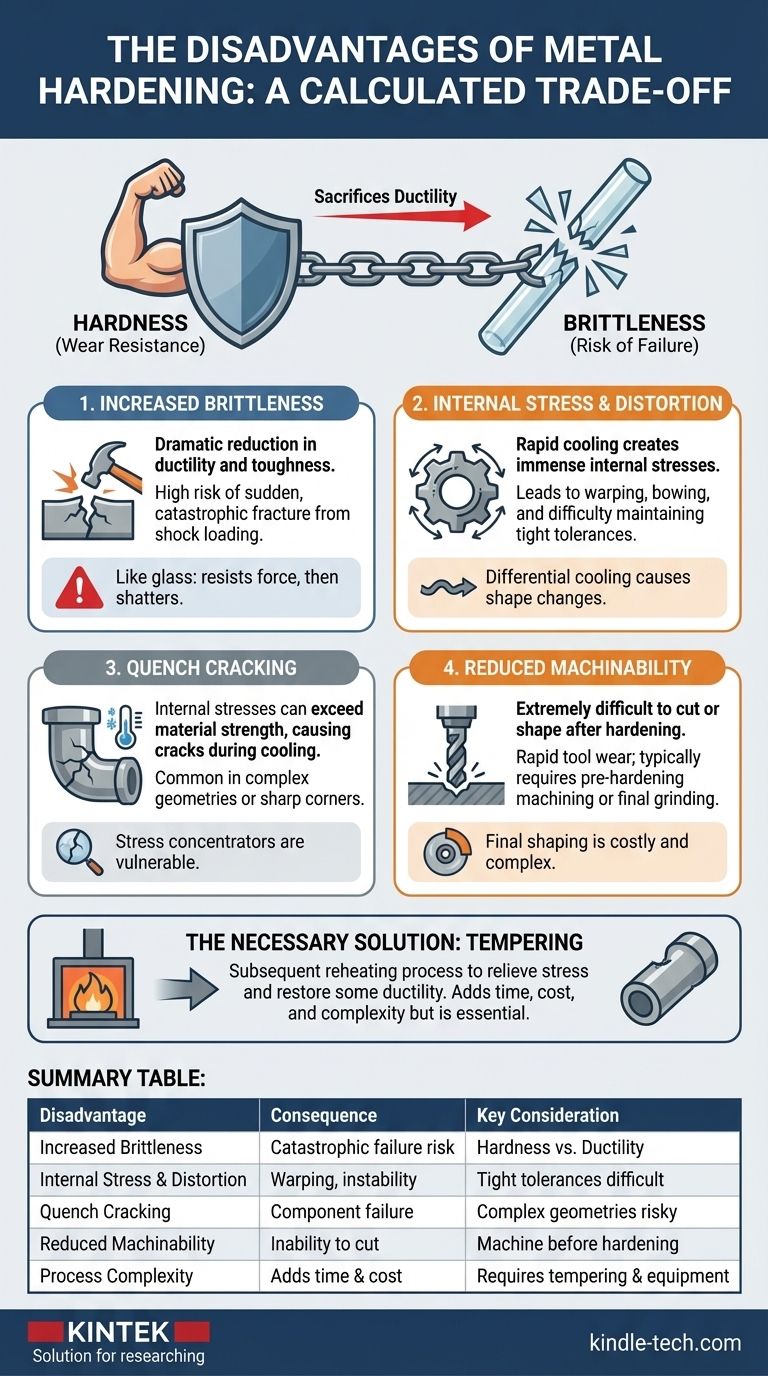

While essential for achieving high strength and wear resistance, the metal hardening process is not without significant drawbacks. The primary disadvantages are a dramatic increase in brittleness, the introduction of high internal stresses that can cause distortion or cracking, and a significant reduction in the material's machinability. These trade-offs must be carefully managed to prevent unexpected component failure.

The fundamental trade-off of hardening is sacrificing ductility for hardness. This exchange makes the material more brittle and introduces internal stresses that can warp, distort, or even crack the component if not properly controlled through subsequent processes like tempering.

The Inherent Trade-off: Hardness vs. Brittleness

The core purpose of hardening is to rearrange the material's crystalline structure to resist deformation, which we perceive as hardness. However, this new, rigid structure comes at a direct cost.

The Inverse Relationship

As a material's hardness increases, its ductility and toughness decrease. A ductile material, like soft steel, will bend or deform under extreme load, absorbing energy before it breaks.

A hardened, brittle material will not. Think of the difference between a rubber band (ductile) and a glass rod (brittle). The hardened metal behaves more like the glass rod, resisting force up to a point and then shattering.

Risk of Catastrophic Failure

This brittleness means a hardened component is more susceptible to catastrophic failure from impact or shock loading. Instead of bending, it is likely to fracture suddenly and without warning, which can be extremely dangerous in critical applications.

Key Disadvantages of the Hardening Process

The rapid cooling, or quenching, that is central to the hardening process is the source of its most significant problems. The extreme thermal shock induces changes that can compromise the integrity of the part.

Internal Stress and Distortion

When a hot component is quenched, its surface cools and contracts much faster than its core. This differential creates immense internal stresses within the material.

These stresses can relieve themselves by changing the part's shape, leading to warping, bowing, or other distortions. This makes it incredibly difficult to maintain tight dimensional tolerances on complex parts.

The Danger of Quench Cracking

In severe cases, the internal stresses generated during quenching can exceed the material's ultimate tensile strength. When this happens, the component will crack during the cooling process.

This phenomenon, known as quench cracking, is more likely in parts with complex geometries, sharp internal corners, or drastic changes in cross-section, as these features act as stress concentrators.

Reduced Machinability

A fully hardened piece of steel is extremely difficult to cut, drill, or shape using conventional machine tools. Attempting to do so results in rapid tool wear and is often impractical and costly.

For this reason, nearly all machining operations are performed on the material in its softer, annealed state before it undergoes hardening. Any final shaping required after hardening must typically be done through grinding.

Understanding the Trade-offs and Process Complexities

Hardening is not a single, isolated step but part of a sequence that requires careful control and often necessitates additional processes to be successful.

The Necessity of Tempering

Because of the extreme brittleness induced by hardening, parts are almost always subjected to a subsequent heat treatment process called tempering.

Tempering involves reheating the part to a lower temperature to relieve some of the internal stress and restore a small amount of ductility. This makes the component tougher and less prone to shattering, but it also slightly reduces the peak hardness. Tempering adds time, cost, and complexity to the overall manufacturing process.

Dimensional Instability

The change in crystalline structure during hardening can cause the material to change in volume. This means a part's final dimensions after hardening and tempering may not be identical to its pre-treated dimensions, a critical factor for precision components.

Cost and Equipment

Proper hardening requires specialized equipment, including high-temperature furnaces, controlled atmospheres (like the vacuum furnaces mentioned in technical literature), and specific quenching media (gas, oil, water). This adds significant capital and operational costs to production.

Making the Right Choice for Your Application

Successfully using hardening requires acknowledging its disadvantages and planning for them in your design and manufacturing process.

- If your primary focus is maximum wear resistance and surface hardness: Hardening is necessary, but you must pair it with a robust tempering process and design the part to minimize stress concentrations.

- If your primary focus is toughness and impact resistance: Avoid full hardening or use a more localized method like case hardening, ensuring the core of the component remains ductile.

- If your primary focus is maintaining tight dimensional tolerances: You must account for potential distortion and may need to perform final grinding or lapping operations after heat treatment.

Ultimately, treating hardening as a calculated trade-off between strength and brittleness, rather than a simple upgrade, is the key to successful engineering design.

Summary Table:

| Disadvantage | Primary Consequence | Key Consideration |

|---|---|---|

| Increased Brittleness | Risk of catastrophic failure from impact | Hardness gained at the cost of ductility |

| Internal Stress & Distortion | Warping, bowing, dimensional instability | Difficult to maintain tight tolerances |

| Quench Cracking | Component failure during cooling | Especially risky with complex geometries |

| Reduced Machinability | Inability to cut or drill after hardening | Most machining must be done beforehand |

| Process Complexity & Cost | Requires tempering, specialized equipment | Adds time and expense to manufacturing |

Need precise thermal processing for your lab materials? The challenges of hardening—like brittleness and distortion—require expert control and the right equipment. KINTEK specializes in advanced lab furnaces and consumables that provide the precise temperature management and controlled atmospheres needed to mitigate these disadvantages. Whether you're working on R&D or quality control, our solutions help you achieve optimal material properties reliably. Let's discuss your specific application requirements – contact our experts today to enhance your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment