Temperature is the single most influential variable in any metalworking process. It directly dictates a metal's formability, its final strength, and its internal microstructure. By controlling heat, we control the very properties that make a metal useful for a specific application.

The core principle is this: Temperature provides the thermal energy required for atoms within the metal's crystal structure to move. This atomic movement, known as diffusion, is the fundamental mechanism that allows us to shape, strengthen, or soften a metal.

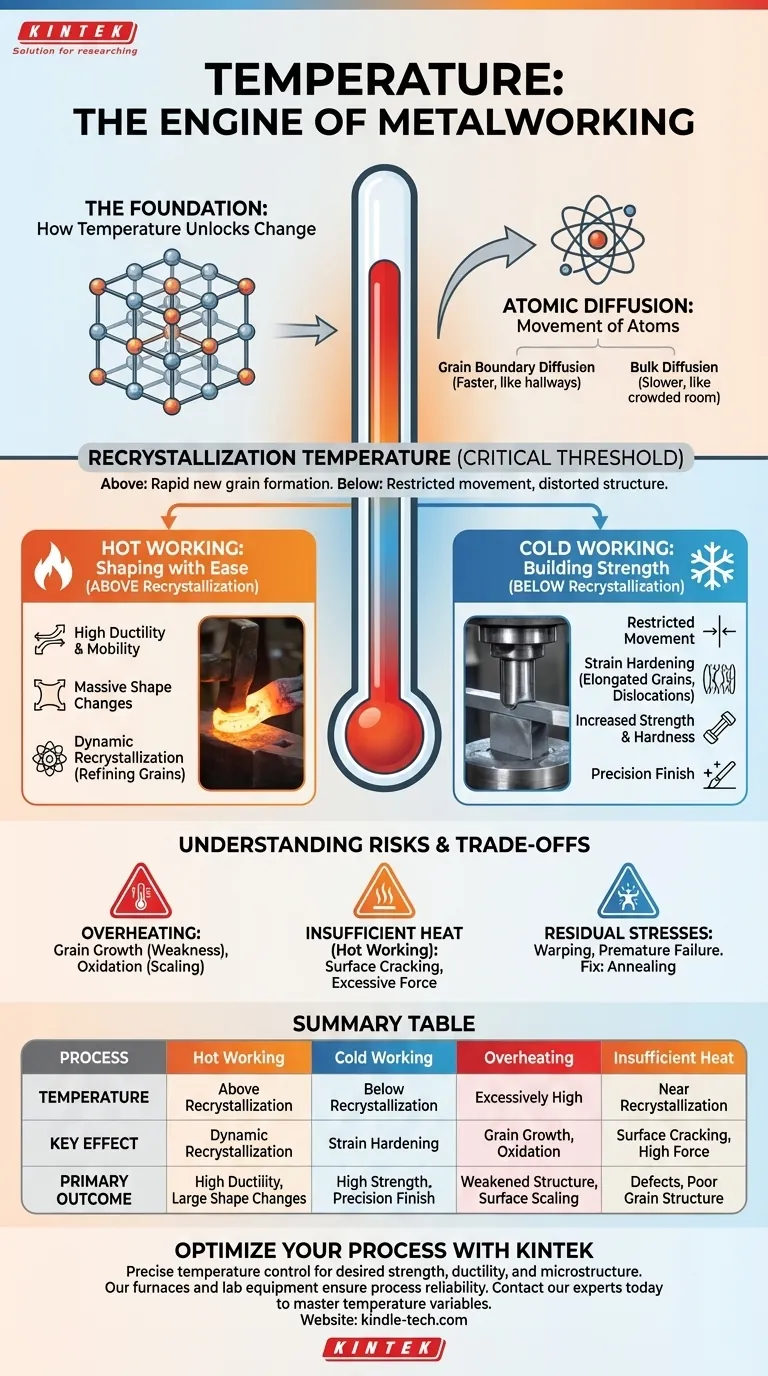

The Foundation: How Temperature Unlocks Change

At a microscopic level, a metal is a crystalline solid made of grains. The properties of the metal are determined by the size, shape, and orientation of these grains. Temperature is the primary tool for manipulating this grain structure.

The Engine of Change: Atomic Diffusion

All significant changes in a metal's structure are driven by diffusion, the movement of atoms. Temperature governs the rate of this movement.

The reference to grain boundary diffusion describes atoms moving more easily along the borders between grains, like using hallways to move through a building. Bulk diffusion is atoms moving through the grains themselves, a much slower and more energy-intensive process, like pushing through a crowded room.

The Critical Threshold: Recrystallization Temperature

Every metal has a recrystallization temperature. This isn't a single sharp point like melting, but rather a temperature range.

Above this temperature, new, strain-free grains can form very rapidly. Below it, atomic movement is too restricted for new grains to form, and any deformation will distort the existing grain structure.

Why This Temperature Matters

Understanding the recrystallization temperature is the key to differentiating between the two primary modes of metalworking: hot working and cold working. Each approach uses temperature to achieve fundamentally different outcomes.

Hot Working vs. Cold Working: A Tale of Two Processes

The choice to work a metal above or below its recrystallization temperature has profound consequences for the process and the final product.

Hot Working: Shaping with Ease

Hot working is any deformation process performed above the metal's recrystallization temperature.

Because atoms are highly mobile, the metal is soft and ductile. This allows for massive shape changes with relatively low force. As the metal is deformed, its grains are simultaneously being broken down and reformed into a new, finer, and more uniform structure, a process called dynamic recrystallization.

Cold Working: Building Strength

Cold working is performed below the recrystallization temperature.

Here, atomic movement is restricted. When the metal is deformed, its grains are elongated and distorted. This creates a dense web of internal dislocations that interfere with each other, a phenomenon known as strain hardening or work hardening. The result is a significant increase in strength and hardness, but a decrease in ductility.

Understanding the Trade-offs and Risks

Temperature control is not just about choosing hot or cold working; it's about precision. Deviations can introduce severe defects and compromise the integrity of the part.

The Danger of Overheating

If a metal is heated too far above its recrystallization temperature, or held there for too long, grains will begin to grow excessively. This grain growth results in a coarse structure that is weaker and has lower toughness. Extreme overheating can also lead to surface oxidation (scaling), which degrades the surface finish and results in material loss.

The Challenge of Insufficient Heat

In hot working, allowing the metal to cool too much before deformation is complete can be catastrophic. As the temperature drops towards the recrystallization point, the material becomes much harder to deform. This can lead to surface cracking, excessive force requirements on machinery, and an undesirable final grain structure.

The Hidden Risk: Residual Stresses

Uneven cooling after a working process can lock residual stresses into the material. These internal stresses can cause warping over time or lead to premature failure under load. Controlled cooling or subsequent heat treatments like annealing (heating to relieve stress) are often required to mitigate this risk.

Matching Temperature Strategy to Your Goal

Your approach to temperature control should be dictated entirely by the desired properties of the final component.

- If your primary focus is large-scale shaping and low forming forces: Hot working is the correct path, as it leverages high ductility and dynamic recrystallization.

- If your primary focus is achieving maximum strength and a precise surface finish: Cold working is the superior method, as strain hardening provides strength and the process allows for tight dimensional tolerances.

- If your primary focus is component reliability and longevity: Precise temperature control throughout the process and during post-process heat treatments like annealing or tempering is non-negotiable to avoid defects.

Ultimately, mastering the effect of temperature is to master the art of metallurgy itself.

Summary Table:

| Process | Temperature Range | Key Effect on Metal | Primary Outcome |

|---|---|---|---|

| Hot Working | Above Recrystallization | Dynamic Recrystallization | High Ductility, Large Shape Changes |

| Cold Working | Below Recrystallization | Strain Hardening | High Strength, Precision Finish |

| Overheating | Excessively High | Grain Growth, Oxidation | Weakened Structure, Surface Scaling |

| Insufficient Heat | Near Recrystallization | Surface Cracking, High Force | Defects, Poor Grain Structure |

Optimize Your Metalworking Process with KINTEK

Precise temperature control is the key to achieving the desired strength, ductility, and microstructure in your metal components. Whether your goal is large-scale shaping via hot working or achieving high strength through cold working, the right laboratory equipment is essential for process development and quality control.

KINTEK specializes in lab equipment and consumables, serving the precise needs of metallurgy and materials science laboratories. Our furnaces and temperature control systems help you accurately simulate and analyze metalworking processes to prevent defects and ensure component reliability.

Contact our experts today to discuss how KINTEK's solutions can help you master temperature variables and enhance your metalworking outcomes.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory oven utilized in NZSP solid electrolyte processing? Master Precise Solvent Removal for Research

- How does a sputtering system work? Achieve Superior Thin-Film Deposition for Your Lab

- What is the HIP process of metal? Achieve Perfect Density for Critical Components

- How do high-performance ultrasonic homogenizers facilitate LDH exfoliation? Master Precise Electrostatic Assembly

- What are the two structures of molds? Understanding Hyphae and Mycelium

- What is conventional sintering? Transform Powder into Dense, High-Strength Materials

- How does heat treatment affect microstructure? Mastering the Balance Between Hardness and Toughness

- How does a laboratory magnetic stirrer contribute to pre-mixing? Master Your Photocatalytic Reaction Baselines