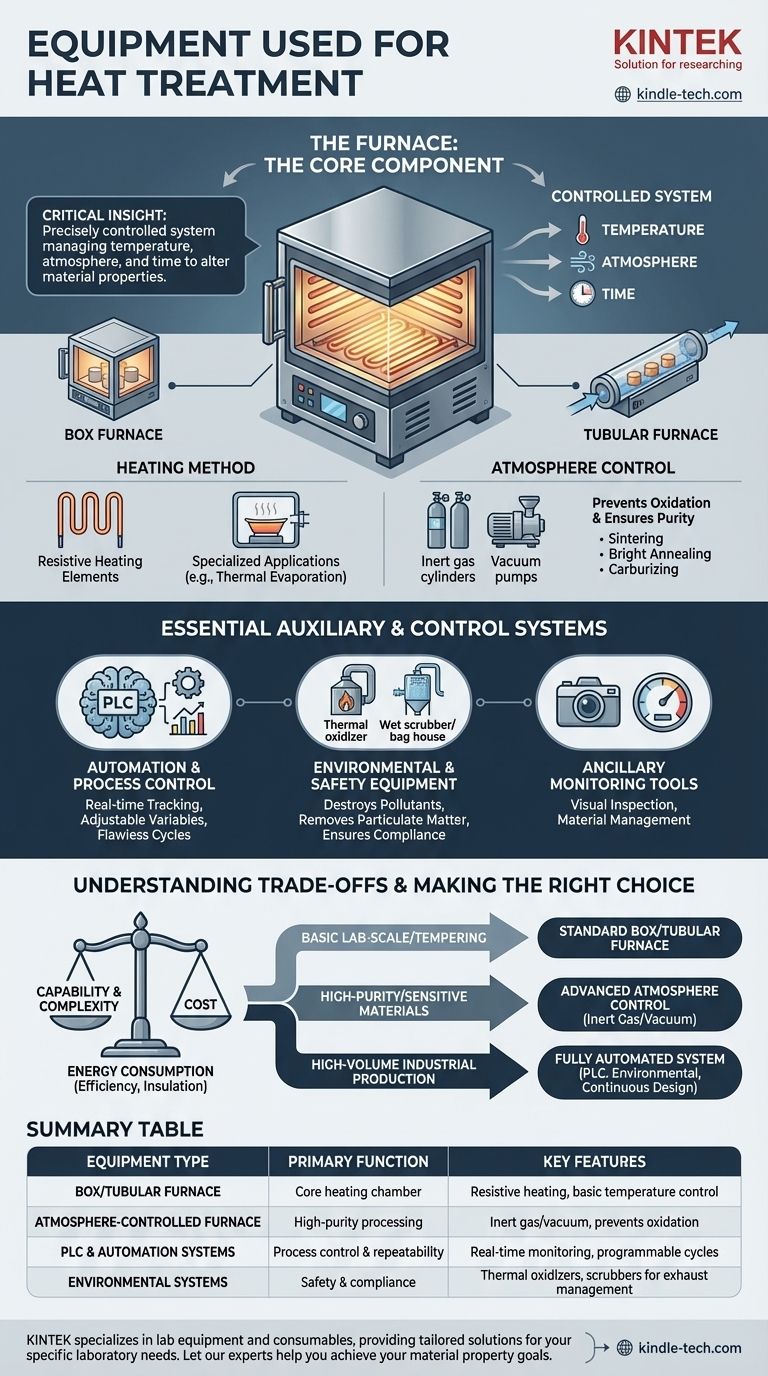

At its core, the primary piece of equipment used for heat treatment is the furnace. However, a complete thermal processing solution is a system that also includes essential auxiliary equipment for process control, environmental management, and testing to ensure the desired material properties are achieved. The most common way to categorize these furnaces is by the shape and orientation of their heating chamber, such as a box furnace or a tubular furnace.

The critical insight is that heat treatment equipment is not merely a device for generating heat. It is a precisely controlled system where the furnace's ability to manage temperature, atmosphere, and time is paramount to altering a material’s physical and chemical properties successfully.

The Core Component: The Furnace

The furnace is the heart of any heat treatment operation. Its design and capabilities directly determine which processes can be performed and to what degree of precision.

How Furnaces are Categorized

The most useful naming convention for furnaces is based on their general shape. This simple method provides immediate insight into the equipment's form and potential application.

Common examples include box furnaces, which are general-purpose chambers, and tubular furnaces, which are ideal for processing samples in a more controlled, linear fashion.

The Critical Function of Heating

The method of heating is fundamental. Many furnaces use resistive heating elements, where an electric current is passed through a material like a metal ribbon or coil to generate heat.

In some specialized applications, like thermal evaporation, a specific "resistance boat" holds the material to be heated, ensuring it melts and evaporates in a controlled manner.

The Importance of Atmosphere Control

Many heat treatment processes require a highly controlled environment to prevent unwanted chemical reactions, like oxidation.

Furnaces designed for processes like sintering, bright annealing, or carburizing must be capable of maintaining a specific atmosphere, often using inert gases, to protect the material being treated. This is essential in industries like aerospace and automotive where material integrity is non-negotiable.

Essential Auxiliary and Control Systems

A modern heat treatment setup extends far beyond the furnace chamber. A range of support systems is necessary for automation, safety, and environmental compliance.

Automation and Process Control

Modern systems rely on automation to ensure repeatability and precision. A Programmable Logic Controller (PLC) allows operators to track and adjust variables like temperature and gas flow in real-time, executing complex heating and cooling cycles flawlessly.

Environmental and Safety Equipment

Heat treatment can produce byproducts that must be managed. This is the role of auxiliary environmental equipment.

- Thermal Oxidizers: Destroy hazardous air pollutants.

- Wet Scrubbers & Bag Houses: Remove particulate matter from exhaust streams.

These systems ensure the operation is safe and complies with environmental regulations.

Ancillary Monitoring Tools

To observe and manage the process, various testing and support tools are used. These can include removable lights for visual inspection within the chamber or physical "dams" and "bed disturbers" to manage the material being processed inside the furnace.

Understanding the Trade-offs

Selecting the right equipment involves balancing capability, complexity, and cost. The most advanced system is not always the best choice.

Matching Equipment to the Process

A furnace's capabilities must align with the process requirements. A simple furnace for tempering does not need the sophisticated atmosphere controls required for carbonitriding. Using the wrong equipment will fail to produce the desired material properties.

Complexity and Cost

A simple, general-purpose box furnace for a lab is significantly less expensive and complex than a large-scale, fully automated industrial furnace with advanced PLC and atmosphere controls. The investment must be justified by the required precision and production volume.

Energy Consumption

Heat treatment is an energy-intensive process. Key trade-offs in furnace selection often revolve around thermal efficiency, insulation quality, and the effectiveness of the heating elements, all of which have a direct impact on long-term operational costs.

Making the Right Choice for Your Goal

The ideal equipment configuration is dictated entirely by the specific outcome you need to achieve.

- If your primary focus is basic lab-scale testing or simple tempering: A standard box or tubular furnace with reliable temperature control is perfectly adequate.

- If your primary focus is high-purity processing or sensitive materials (like bright annealing or sintering): A furnace with advanced atmosphere control (e.g., inert gas or vacuum capabilities) is non-negotiable.

- If your primary focus is high-volume industrial production: A fully automated system with a PLC, integrated environmental controls, and potentially a continuous furnace design is essential for efficiency and repeatability.

Ultimately, selecting the right heat treatment equipment is about matching the tool's capabilities to the precise material transformation your process requires.

Summary Table:

| Equipment Type | Primary Function | Key Features |

|---|---|---|

| Box/Tubular Furnace | Core heating chamber | Resistive heating, basic temperature control |

| Atmosphere-Controlled Furnace | High-purity processing | Inert gas/vacuum, prevents oxidation |

| PLC & Automation Systems | Process control & repeatability | Real-time monitoring, programmable cycles |

| Environmental Systems | Safety & compliance | Thermal oxidizers, scrubbers for exhaust management |

Ready to optimize your heat treatment process? KINTEK specializes in lab equipment and consumables, providing tailored solutions from reliable box furnaces for lab testing to advanced systems with precise atmosphere control for sintering or annealing. Let our experts help you select the perfect equipment to achieve your material property goals. Contact us today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost