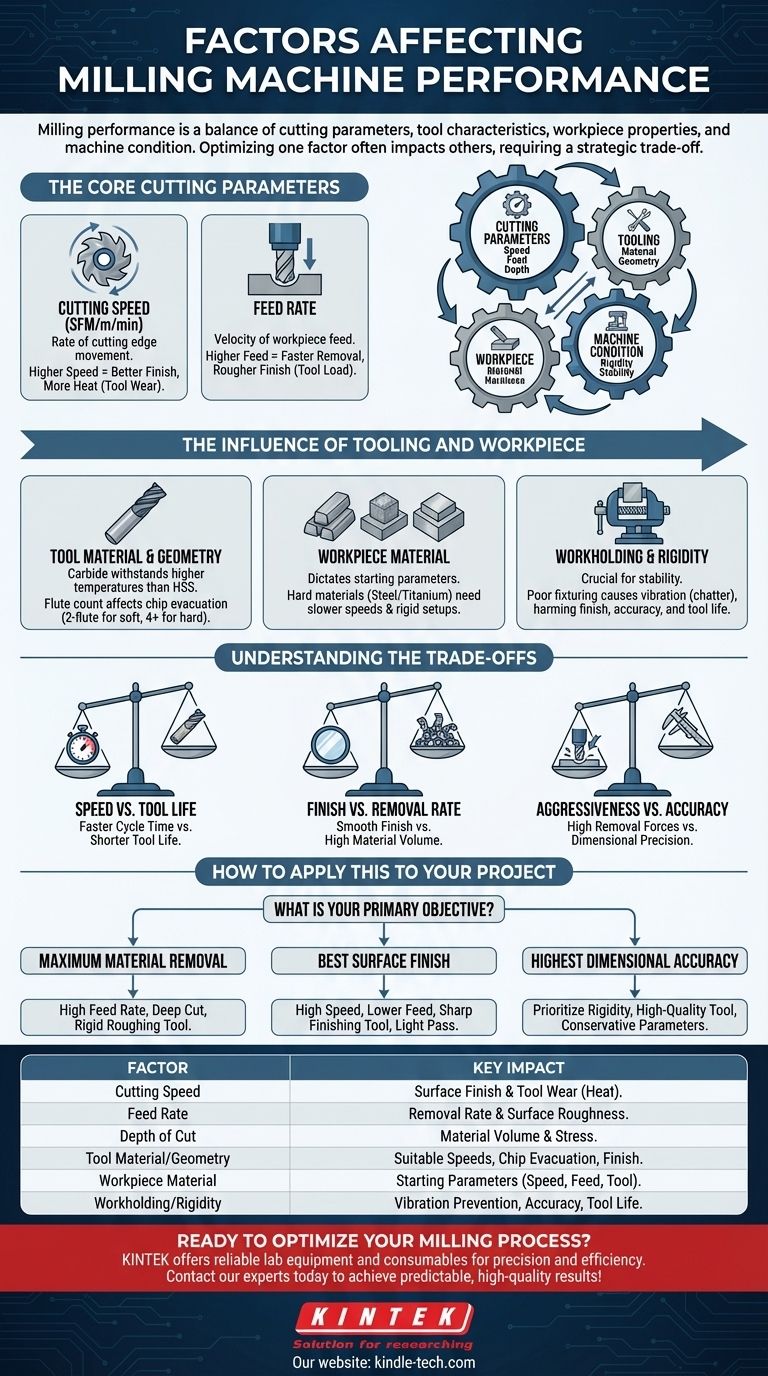

The performance of a milling machine is a balance of several interconnected factors. At the most fundamental level, these are the cutting parameters (speed, feed, and depth of cut), the characteristics of the cutting tool, the properties of the workpiece material, and the physical condition and rigidity of the machine itself.

The central challenge in milling is not just knowing these factors, but understanding that they exist in a system of trade-offs. Optimizing one factor, such as cutting speed, will inevitably impact others, like tool life and surface finish. True control comes from balancing these trade-offs to meet a specific goal.

The Core Cutting Parameters

These three variables are the most direct inputs an operator controls. They are often referred to as "speeds and feeds" and form the foundation of any milling operation.

Cutting Speed

Cutting speed refers to the rate at which the tool's cutting edge moves across the material surface. It is measured in surface feet per minute (SFM) or meters per minute (m/min).

A higher cutting speed generally produces a better surface finish but also generates more heat. This excess heat is the primary cause of premature tool wear.

Feed Rate

Feed rate is the velocity at which the workpiece is fed into the rotating cutter. It dictates how much material each cutting edge (flute) of the tool removes per revolution.

Increasing the feed rate is the most common way to shorten machining time. However, an excessively high feed rate can lead to a rough surface finish, high tool load, and potential tool breakage.

Depth of Cut

This is how deep the tool cuts into the material. It has two components: axial depth (how deep the tool engages along its axis) and radial depth (how far it steps over into the material).

A greater depth of cut removes more material faster but also places significantly more stress on the tool, the spindle, and the machine frame, which can lead to tool deflection and vibration.

The Influence of Tooling and Workpiece

The physical objects involved—the tool and the part—are just as critical as the parameters you set.

Tool Material and Geometry

The tool's composition and shape are paramount. Carbide tools can withstand much higher temperatures than High-Speed Steel (HSS), allowing for faster cutting speeds.

Tool geometry, such as the number of flutes, also plays a key role. A two-flute end mill provides excellent chip evacuation for soft materials like aluminum, while a four-or-more-flute mill offers more strength and a better finish in harder materials like steel.

Workpiece Material

The material being cut fundamentally dictates the starting point for all other parameters.

Hard, abrasive materials like stainless steel or titanium require much slower cutting speeds and more rigid setups than soft materials like aluminum or plastic.

Workholding and Rigidity

How the workpiece is held (fixturing) is a frequent source of problems. A part that is not held securely will vibrate during cutting.

This vibration, often called "chatter," is disastrous for surface finish, dimensional accuracy, and tool life. A rigid setup—from the machine to the tool holder to the workpiece fixture—is non-negotiable for quality work.

Understanding the Trade-offs

Success in milling comes from managing compromises. Pushing one variable to its limit will always have consequences for another.

Speed vs. Tool Life

This is the classic trade-off. Running a tool at the upper end of its recommended speed range will reduce cycle time but will wear out the tool much faster. This increases tooling costs and the risk of in-process tool failure.

Finish vs. Removal Rate

Achieving a smooth, mirror-like surface finish requires a light depth of cut and a moderate feed rate. Conversely, removing a large volume of material quickly demands a deep cut and a high feed rate, which inherently leaves a rougher surface. For this reason, operations are often split into a "roughing" pass followed by a "finishing" pass.

Aggressiveness vs. Accuracy

Aggressive cuts with high material removal rates place significant force on the cutting tool, causing it to deflect slightly. This deflection can compromise the dimensional accuracy of the final part. For high-precision components, lighter cuts are used to minimize these forces.

How to Apply This to Your Project

Your optimal settings are determined entirely by your primary objective for the operation.

- If your primary focus is maximum material removal: Prioritize a high feed rate and a deep axial/radial depth of cut, using a rigid carbide tool designed for roughing.

- If your primary focus is the best possible surface finish: Use a high cutting speed but a lower feed rate, ensure you are using a sharp tool with the correct geometry, and take a very light final "finishing" pass.

- If your primary focus is the highest dimensional accuracy: Prioritize rigidity above all else in your workholding, use a high-quality tool to minimize deflection, and use conservative parameters to reduce cutting forces.

By systematically considering each of these factors, you move from simply guessing at parameters to engineering a predictable and successful outcome.

Summary Table:

| Factor | Key Impact on Milling |

|---|---|

| Cutting Speed (SFM/m/min) | Surface finish quality & tool wear due to heat generation. |

| Feed Rate | Material removal rate & surface finish roughness. |

| Depth of Cut | Volume of material removed & stress on tool/machine. |

| Tool Material/Geometry | Suitable cutting speeds, chip evacuation, and part finish. |

| Workpiece Material | Dictates starting parameters for speed, feed, and tool choice. |

| Workholding/Rigidity | Prevents vibration (chatter), ensuring accuracy and tool life. |

Ready to optimize your milling process? The right lab equipment is the foundation of precision and efficiency. KINTEK specializes in providing reliable lab equipment and consumables to support your laboratory's unique needs. Whether you're focused on material removal, surface finish, or dimensional accuracy, we have the solutions to help you achieve predictable, high-quality results. Contact our experts today to discuss how we can support your projects!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Powerful Plastic Crusher Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production