At its core, a laboratory electric furnace is defined by a specific combination of performance and construction features. These include rapid heating capabilities, excellent temperature uniformity within the chamber, and a compact design, all achieved through the use of advanced materials like all-fiber insulation and high-temperature resistance wire heating elements.

A laboratory electric furnace is not simply a high-temperature oven. Its key features are engineered as a complete system to provide the rapid, repeatable, and precise thermal control that is non-negotiable for scientific analysis and materials processing.

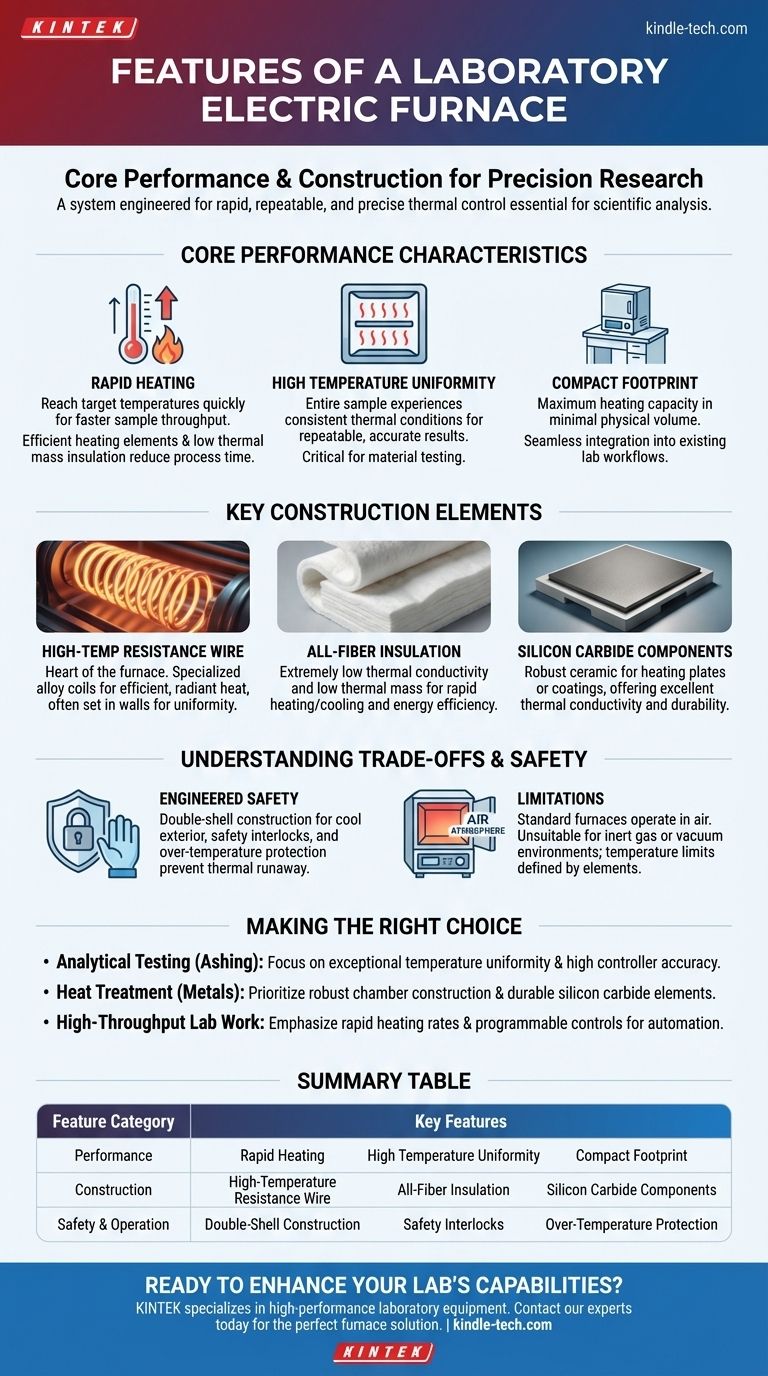

Core Performance Characteristics

The value of a laboratory furnace is measured by its performance. Three characteristics are paramount for ensuring reliable and efficient operation in a professional setting.

Rapid Heating

The ability to reach a target temperature quickly is essential for lab productivity. This is achieved through efficient heating elements and low thermal mass insulation.

Rapid heating allows for faster sample throughput and reduces the total time required for thermal processes like ashing, annealing, or elemental analysis.

High Temperature Uniformity

Perhaps the most critical feature, temperature uniformity ensures that the entire sample within the chamber experiences the same thermal conditions.

This consistency is vital for repeatable experiments and accurate material testing, as temperature gradients could skew results or cause inconsistent material transformations. Heating elements embedded in the walls and floor help distribute heat evenly to achieve this.

Compact Footprint

Laboratory bench space is always at a premium. These furnaces are designed to provide maximum heating capacity in the smallest possible physical volume.

This efficient design makes it easier to integrate the furnace into an existing lab workflow without significant reorganization.

Key Construction and Design Elements

The performance of a lab furnace is a direct result of its underlying construction. The materials chosen are optimized for thermal efficiency, durability, and safety.

High-Temperature Resistance Wire

This is the heart of the furnace. Coils made from specialized alloys are used as heating elements, converting electrical energy into radiant heat with very high efficiency.

These elements are typically set into the furnace walls and heating plates, allowing them to heat the chamber from multiple sides for better uniformity.

All-Fiber Insulation Layer

Modern furnaces use lightweight, all-fiber ceramic insulation instead of dense firebrick. This material has extremely low thermal conductivity, keeping heat inside the chamber.

Its low thermal mass is the key to rapid heating and cooling, as very little energy is wasted heating the insulation itself. This also makes the furnace more energy-efficient.

Silicon Carbide Components

Silicon carbide is a robust ceramic used for components like heating plates or coatings. It offers excellent thermal conductivity and durability at high temperatures.

Using a silicon carbide plate on the furnace floor helps distribute heat evenly and provides a hard-wearing surface that can withstand chemical exposure and thermal shock.

Understanding the Trade-offs and Safety

While highly effective, it's important to understand the operational context and inherent safety considerations of these instruments.

Engineered for Safe Operation

Safety is a primary design concern. Features like double-shell construction keep the outer surface cool to the touch, preventing burns.

Additionally, most furnaces include safety interlocks that cut power to the heating elements when the door is opened, along with over-temperature protection circuits to prevent thermal runaway.

Limitations of Standard Furnaces

A standard electric furnace operates in an ambient air atmosphere. This makes it unsuitable for processes that require an inert gas or a vacuum environment, which would necessitate a more specialized and expensive furnace design.

Furthermore, the maximum achievable temperature is determined by the type of heating element and insulation used, creating distinct performance tiers.

Making the Right Choice for Your Application

Selecting a furnace requires matching its features to your specific goal.

- If your primary focus is precise analytical testing (e.g., ashing): Prioritize exceptional temperature uniformity and a controller with high accuracy to ensure your results are repeatable.

- If your primary focus is general heat treatment of metals: Look for a robust chamber construction with durable silicon carbide elements or plates that can withstand repeated, heavy use.

- If your primary focus is high-throughput laboratory work: Emphasize rapid heating rates and programmable controls to automate cycles and maximize efficiency.

Ultimately, understanding how these core features work together empowers you to select and operate a furnace as a true precision instrument.

Summary Table:

| Feature Category | Key Features |

|---|---|

| Performance | Rapid Heating, High Temperature Uniformity, Compact Footprint |

| Construction | High-Temperature Resistance Wire, All-Fiber Insulation, Silicon Carbide Components |

| Safety & Operation | Double-Shell Construction, Safety Interlocks, Over-Temperature Protection |

Ready to enhance your lab's capabilities with a precision electric furnace?

At KINTEK, we specialize in providing high-performance laboratory equipment, including electric furnaces engineered for precise temperature control, rapid heating, and safe operation. Whether your application requires analytical testing, heat treatment, or high-throughput processing, our solutions are designed to deliver the reliability and accuracy your work demands.

Contact our experts today to discuss your specific needs and find the perfect furnace for your laboratory.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results