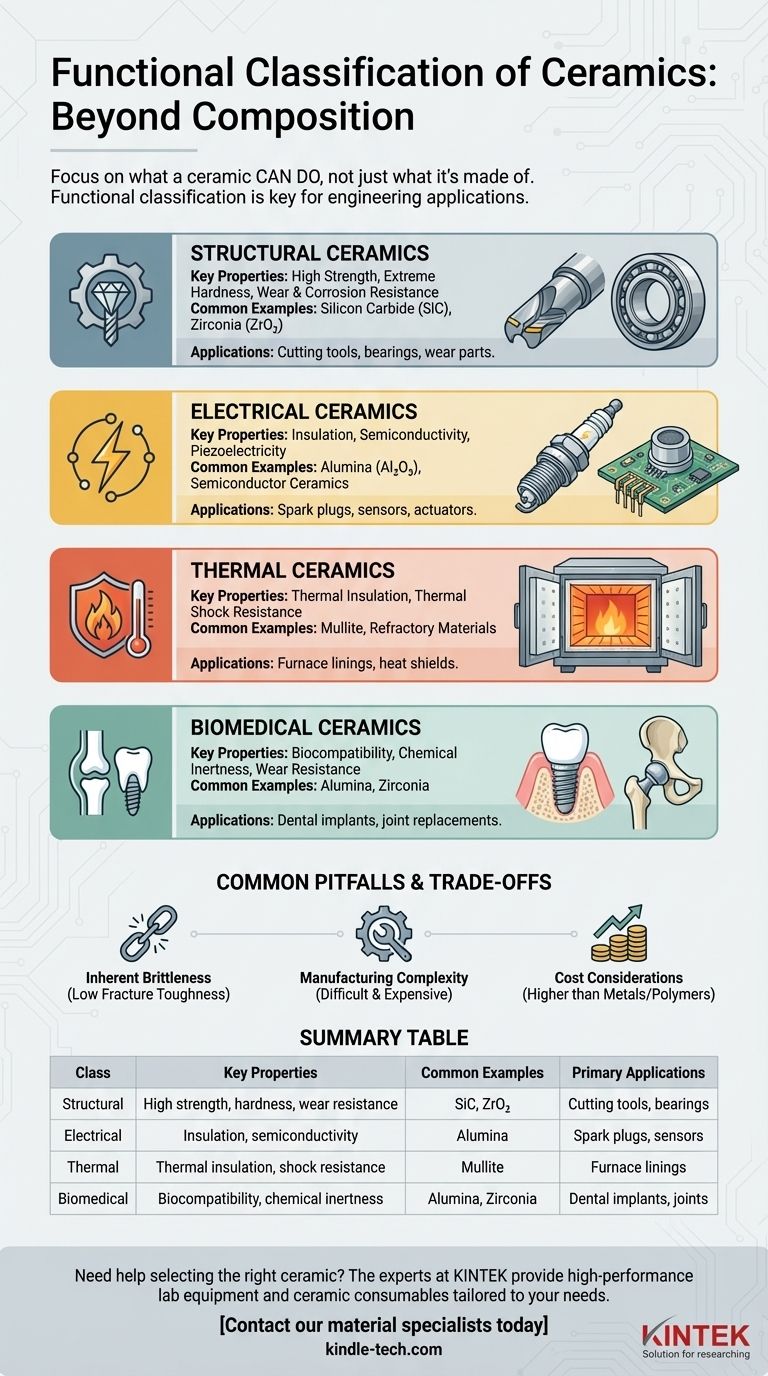

In practice, ceramics are classified by their function. While their chemical composition is important, their functional classification—which is based on their unique properties and how they are used—is far more relevant for engineering and design. The primary functional categories include structural, electrical, thermal, and biomedical ceramics.

Understanding a ceramic's functional classification is the key to material selection. It shifts the focus from "What is it made of?" to "What can it do?", which is the fundamental question for any practical application.

Why Functional Classification Matters

Classifying materials helps us organize our knowledge and make informed decisions. When it comes to advanced ceramics, looking at them through a functional lens provides the most direct path to solving a problem.

Composition vs. Function

A compositional classification groups ceramics by their chemical makeup. This includes categories like oxides (alumina, zirconia), nitrides (silicon nitride), and carbides (silicon carbide). This is useful for materials scientists but doesn't immediately tell an engineer how to use the material.

A functional classification groups ceramics by their primary role in an application. This approach directly connects a material's inherent properties—like hardness, electrical resistivity, or biocompatibility—to a real-world engineering challenge.

The Primary Functional Classes of Ceramics

Advanced ceramics are selected for applications where their specific properties provide a significant advantage over other materials like metals or polymers.

Structural Ceramics

These materials are chosen for their exceptional mechanical properties. They are defined by their high strength, extreme hardness, and resistance to wear and corrosion, especially at high temperatures.

Common examples include silicon carbide (SiC) for abrasive cutting tools and zirconia (ZrO₂) for durable cutting blades and bearings.

Electrical Ceramics

This broad category covers a range of electrical behaviors. These ceramics are chosen for their ability to control or respond to electrical fields in specific ways.

Key sub-types include insulators like alumina (Al₂O₃) used in spark plugs, semiconductors used in sensors, and piezoelectric materials that convert mechanical stress into an electrical charge (and vice-versa).

Thermal Ceramics

These ceramics are selected for their performance in extreme thermal environments. Their primary role is either to block heat or to withstand it without degrading.

Thermal insulators like mullite are used for furnace linings and heat shields. Their low thermal conductivity prevents heat transfer. Other ceramics are prized for high thermal shock resistance, allowing them to survive rapid temperature changes.

Biomedical Ceramics

Biomedical ceramics are valued for their biocompatibility, meaning they can exist within the human body without causing an adverse reaction. They are also chemically inert and highly resistant to wear.

Materials like high-purity alumina and zirconia are frequently used in dental implants and hip joint replacements because they are hard, wear-resistant, and integrate well with the body.

Common Pitfalls and Trade-offs

While ceramics offer superior performance in specific areas, their properties also come with significant trade-offs that are critical to understand during the design process.

Inherent Brittleness

The most significant limitation of most ceramics is their low fracture toughness, or brittleness. Unlike metals, which bend or deform under stress, ceramics tend to fracture suddenly and catastrophically once their elastic limit is exceeded.

Manufacturing Complexity

Ceramics are typically processed from powders at very high temperatures. This makes manufacturing complex shapes difficult and expensive compared to casting or machining metals. Finishing often requires costly diamond grinding.

Cost Considerations

The raw materials and specialized high-temperature processing required for advanced ceramics make them significantly more expensive than most metals and polymers. Their use is typically justified only when their unique properties are absolutely necessary for performance.

Making the Right Choice for Your Application

Choosing the correct ceramic requires aligning the material's functional strengths with the primary demands of your project.

- If your primary focus is mechanical wear and hardness: Select from the class of structural ceramics, such as silicon carbide or zirconia.

- If your primary focus is electrical insulation at high temperatures: An oxide ceramic like alumina is an excellent starting point.

- If your primary focus is biocompatibility and chemical inertness: Your best options are biomedical-grade ceramics like alumina or zirconia.

- If your primary focus is surviving extreme heat or rapid temperature changes: Look to thermal ceramics like mullite or other refractory materials.

By classifying ceramics based on what they do, you can more effectively navigate the options and select a material truly engineered for the task at hand.

Summary Table:

| Functional Class | Key Properties | Common Examples | Primary Applications |

|---|---|---|---|

| Structural | High strength, hardness, wear resistance | Silicon Carbide (SiC), Zirconia (ZrO₂) | Cutting tools, bearings, wear parts |

| Electrical | Insulation, semiconductivity, piezoelectricity | Alumina (Al₂O₃) | Spark plugs, sensors, actuators |

| Thermal | Thermal insulation, shock resistance | Mullite | Furnace linings, heat shields |

| Biomedical | Biocompatibility, chemical inertness | Alumina, Zirconia | Dental implants, joint replacements |

Struggling to select the right ceramic for your specific application?

The experts at KINTEK are here to help. We specialize in providing high-performance lab equipment and ceramic consumables tailored to your unique needs—whether you require structural integrity, electrical insulation, thermal management, or biomedical compatibility.

Contact our material specialists today to discuss your project requirements and discover how our solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Carbon Graphite Boat -Laboratory Tube Furnace with Cover

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

People Also Ask

- Does ceramic break with heat? The Real Culprit is Thermal Shock

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers

- What does ceramic fiber do? Achieve Superior High-Temperature Insulation and Control

- What is the effect of sintering on ceramics? Transforming Powder into High-Performance Materials

- What determines the strength of ceramics? The surprising role of microscopic flaws in brittle failure

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- What are the different types of ceramic styles? A Guide to Earthenware, Stoneware, Porcelain & Bone China

- Why are alumina ceramic discs used as sample supports? Optimize Cathodic Cage Deposition Efficiency