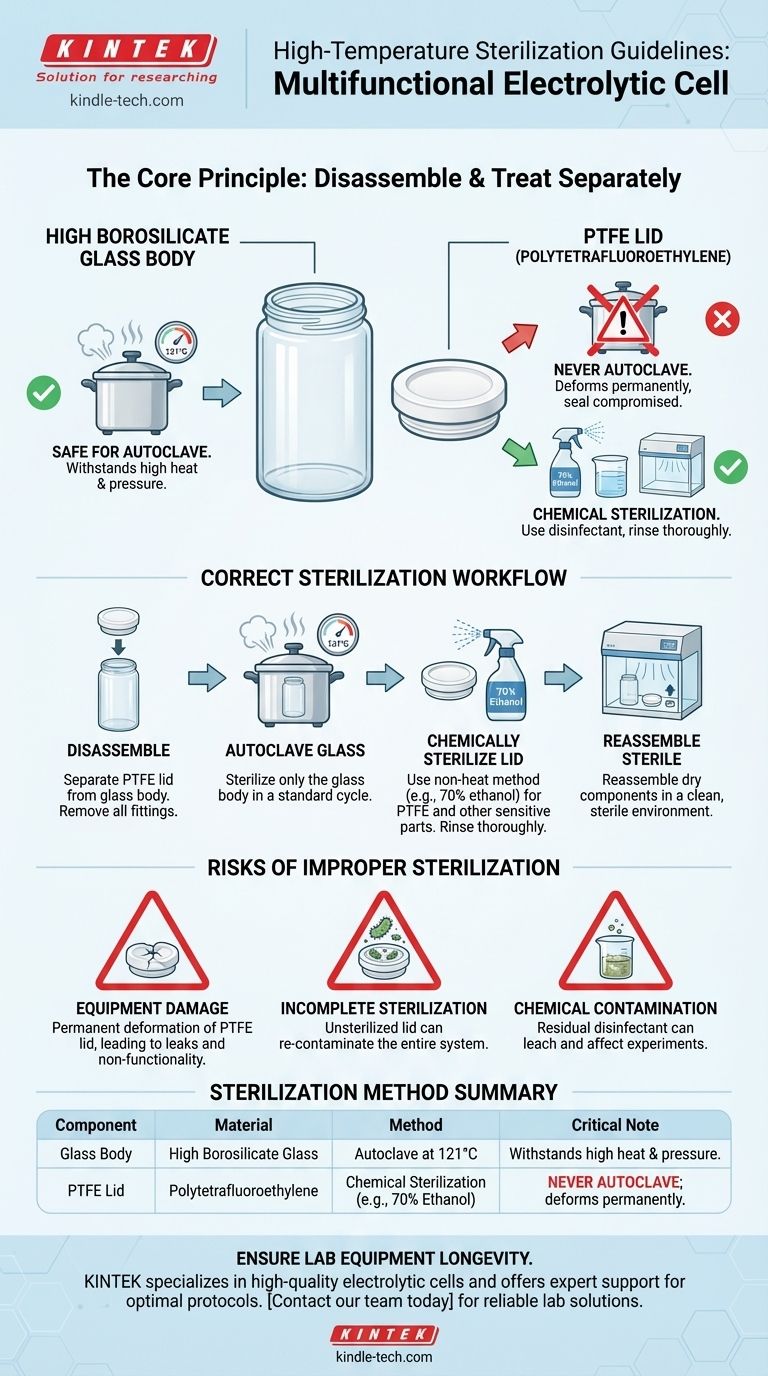

Proper high-temperature sterilization of a multifunctional electrolytic cell is a component-specific process. While the high borosilicate glass body is designed to be autoclaved at 121°C, the polytetrafluoroethylene (PTFE) lid must never be exposed to this level of heat. Heating the entire assembled unit will cause the PTFE lid to expand and permanently deform, compromising the cell's seal and rendering it unusable.

The core principle is to treat the electrolytic cell not as a single object, but as a system of distinct components with different material properties. Effective sterilization hinges on disassembling the unit and applying the correct method to each part separately to prevent irreversible damage.

Understanding Material Limitations: Glass vs. PTFE

To sterilize the cell correctly, you must first understand why its two primary components behave differently under high temperatures.

The Stability of High Borosilicate Glass

The cell body is made from high borosilicate glass. This material is engineered specifically to withstand significant thermal shock and high pressure without cracking or deforming.

This makes it perfectly suitable for sterilization in a standard autoclave at 121°C, which uses high-pressure steam to ensure sterility.

The Vulnerability of the PTFE Lid

The lid is typically made from polytetrafluoroethylene (PTFE). While valued for its chemical resistance, PTFE has a relatively low thermal tolerance compared to glass.

When heated to autoclaving temperatures, PTFE expands significantly. Critically, it does not return to its original shape and dimensions upon cooling, leading to permanent deformation.

The Consequence of Whole-Unit Autoclaving

If the entire cell is autoclaved, the deformed PTFE lid will no longer create a proper seal with the glass body. This will lead to leaks, compromise the anaerobic or controlled atmosphere of your experiment, and ultimately make the cell non-functional.

The Correct Sterilization Workflow

Follow this partitioned workflow to ensure both sterility and the longevity of your equipment.

Step 1: Disassemble the Cell

Carefully separate the PTFE lid from the glass body. Remove any electrodes, tubing, or other fittings. Each component must be handled individually.

Step 2: Autoclave the Glass Body

Place only the high borosilicate glass body into an autoclave. Run a standard cycle at 121°C to achieve high-pressure steam sterilization.

Step 3: Sterilize the PTFE Lid Separately

The PTFE lid and other sensitive components must be sterilized using non-heat methods. The most common approach is chemical sterilization.

Immerse or wipe the lid with a suitable disinfectant, such as 70% ethanol, and then rinse it thoroughly with sterile deionized water to remove any chemical residue that could interfere with your experiment.

Step 4: Reassemble in a Sterile Environment

To maintain sterility, reassemble the dry components in a clean environment, such as a laminar flow hood or a sterile field.

Understanding the Trade-offs and Risks

A proper protocol mitigates risks, but you must be aware of them.

Risk of Equipment Damage

The primary and most costly risk is ignoring the guidelines and autoclaving the entire unit. This action will permanently damage the PTFE lid, requiring a replacement and causing experimental delays.

Risk of Incomplete Sterilization

Sterilizing only the glass body while neglecting the lid creates a false sense of security. The unsterilized lid can easily re-contaminate the entire system, invalidating your results.

Risk of Chemical Contamination

When using chemical sterilization for the lid, residual disinfectants can leach into your electrolyte and affect electrochemical reactions. Thorough rinsing with sterile, high-purity water is non-negotiable.

A Protocol for Safe and Effective Operation

Your approach to handling the cell should be dictated by your immediate goal.

- If your primary focus is performing a sterile experiment: Disassemble the cell, autoclave the glass body at 121°C, and chemically sterilize the PTFE lid before rinsing thoroughly and reassembling in a clean environment.

- If your primary focus is long-term storage: Ensure all components are clean and completely dry, pour out the electrolyte for separate storage, and place the disassembled unit in a dry, humidity-free location.

- If your primary focus is operational safety: Always use personal protective equipment (gloves, goggles), especially when handling electrolytes, and conduct regular inspections of the cell's seals and wiring for signs of wear.

By respecting the distinct material properties of your cell, you ensure the integrity of your experiments and protect the longevity of your equipment.

Summary Table:

| Component | Material | Sterilization Method | Critical Note |

|---|---|---|---|

| Glass Body | High Borosilicate Glass | Autoclave at 121°C | Withstands high heat and pressure |

| PTFE Lid | Polytetrafluoroethylene | Chemical Sterilization (e.g., 70% Ethanol) | Never autoclave; deforms permanently |

Ensure the longevity and performance of your lab equipment. Proper sterilization is critical for reliable results. KINTEK specializes in high-quality laboratory equipment and consumables, including durable electrolytic cells designed for easy maintenance. Our experts can help you select the right equipment and establish optimal protocols for your specific application.

Contact our team today for personalized support and to explore our range of reliable lab solutions.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- How do specialized electrolytic cells facilitate electrochemical testing? Enhance Stainless Steel Corrosion Analysis

- What is the cleaning procedure for a previously used in-situ Raman electrolytic cell? Ensure Peak Optical Clarity

- What are the advantages of electrochemical deposition? Unlock Precision, Cost, and Conformal Coating

- How should failures or malfunctions of the H-type electrolytic cell be handled? Expert Troubleshooting & Repair Guide

- What are the opening configurations for the non-sealed and sealed versions of the electrolysis cell? Optimize Your Electrochemical Setup

- What engineering challenges are addressed by specialized pressure-applying cells for testing all-solid-state batteries?

- What is the typical volume range for a single chamber of the electrolytic cell? A Guide to Sizing for Your Lab

- What are the typical volumes and customization options for an all-PTFE electrolytic cell? Tailor Your Lab Research