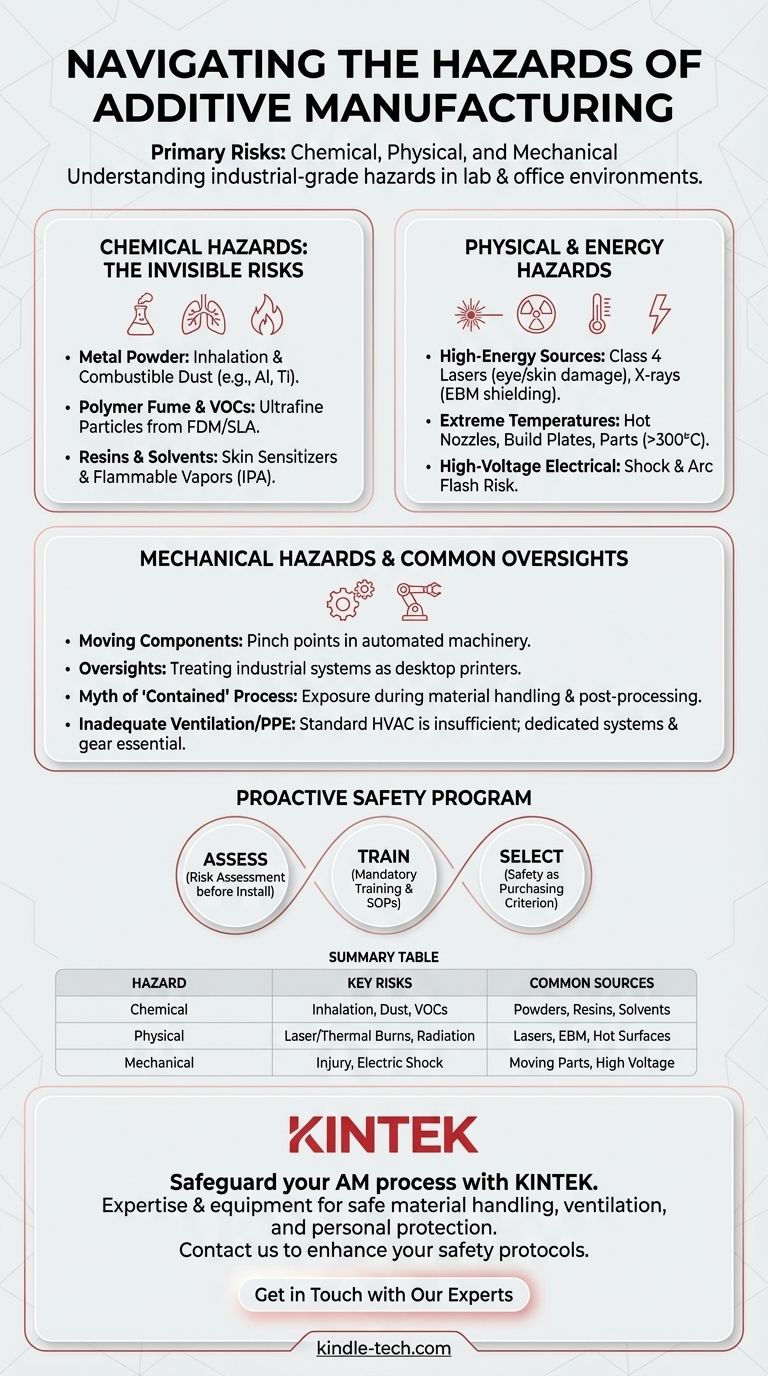

In short, the primary hazards of additive manufacturing fall into three categories: chemical exposure from powders and fumes, physical risks from high-energy sources like lasers and hot surfaces, and mechanical dangers from moving machine components. These risks vary dramatically depending on the specific technology and materials being used, ranging from minor issues with desktop printers to significant industrial hazards with advanced metal systems.

Additive manufacturing uniquely combines the hazards of chemical processing, high-energy systems, and automated machinery into a single process. The greatest oversight is underestimating these industrial-grade risks, especially when the technology is deployed in a lab or office-style environment.

Chemical Hazards: The Invisible Risks

The most frequently underestimated dangers in additive manufacturing are chemical. These risks arise from the raw materials used in the printing process and the byproducts generated when those materials are heated or cured.

Metal Powder Inhalation and Explosibility

Fine metal powders, especially reactive materials like aluminum, titanium, and magnesium, pose a dual threat. Inhaling these microscopic particles can lead to long-term respiratory damage and potential heavy metal poisoning.

Furthermore, when these fine powders are dispersed in the air, they can create a combustible dust cloud. An ignition source, such as a static discharge or spark, can trigger a violent explosion. This makes powder handling and cleanup critical safety procedures.

Polymer Fume and VOC Emissions

Processes that melt plastic filament (FDM) or cure liquid resin (SLA, DLP) release airborne emissions. These include ultrafine particles (UFPs), which can penetrate deep into the lungs, and volatile organic compounds (VOCs).

Prolonged exposure to these emissions in an improperly ventilated space can lead to respiratory irritation and other health concerns. The specific compounds vary by material, making it essential to consult the Safety Data Sheet (SDS) for each polymer.

Handling Resins and Solvents

The photopolymer resins used in SLA and DLP printing are sensitizers, meaning repeated skin contact can lead to severe allergic reactions and chemical burns. Direct contact must always be avoided.

Additionally, solvents like isopropyl alcohol (IPA), commonly used for cleaning finished parts, are highly flammable. Their vapors can accumulate in enclosed spaces, creating a fire or explosion hazard.

Physical and Energy-Related Hazards

The machinery itself contains powerful systems that present immediate physical dangers if safety protocols are not followed.

High-Energy Sources (Lasers and Electron Beams)

Metal powder bed fusion systems rely on high-power energy sources. Class 4 lasers used in Selective Laser Melting (SLM) can cause immediate, permanent eye damage and skin burns from direct or even reflected exposure.

Electron Beam Melting (EBM) systems generate X-rays as a byproduct of operation. These machines require proper shielding to protect operators from radiation exposure.

Extreme Temperatures and Hot Surfaces

Many AM processes involve high temperatures. Print nozzles, heated build plates, and freshly completed parts can be hot enough to cause severe burns. This is particularly true for systems printing with high-performance polymers or metals, where temperatures can exceed several hundred degrees Celsius.

High-Voltage Electrical Systems

Like all industrial machinery, AM systems operate on high-voltage electricity. Improper maintenance or modification creates a significant risk of electric shock or arc flash. Only trained and authorized personnel should ever access the internal electrical components.

Understanding the Pitfalls and Common Oversights

Treating an advanced manufacturing system like a simple office appliance is the most common and dangerous mistake. The context in which the machine operates is just as important as the machine itself.

The Desktop Printer vs. The Industrial System

A desktop FDM printer in an open office presents a relatively low risk, primarily related to VOC emissions and hot surfaces. In contrast, an industrial metal powder bed fusion system is a complex chemical and energy system that demands a dedicated, controlled environment with specialized infrastructure.

The Myth of the "Contained" Process

Hazards are not confined to the build chamber. The greatest exposure often occurs during material loading, part removal, and post-processing. Activities like recovering and sieving unused metal powder, cleaning resin vats, or sanding finished parts release the highest concentrations of hazardous materials.

Inadequate Ventilation and PPE

Standard office HVAC is insufficient for managing the chemical emissions from most AM processes. A dedicated ventilation and exhaust system is crucial. Furthermore, Personal Protective Equipment (PPE)—such as respirators, safety glasses, and chemical-resistant gloves—is not optional; it is a fundamental requirement for safely operating these systems.

How to Implement a Proactive Safety Program

A safe AM operation is built on a foundation of awareness, assessment, and established procedures. Your approach should be tailored to your specific goals and environment.

- If your primary focus is setting up a new AM facility: Conduct a formal risk assessment for each machine before installation, consulting the manufacturer's documentation and material Safety Data Sheets to plan for ventilation, electrical, and PPE needs.

- If your primary focus is ensuring daily operational safety: Implement mandatory, role-specific training programs and enforce strict adherence to standard operating procedures (SOPs) for machine operation, material handling, and maintenance.

- If your primary focus is selecting new AM technology: Make safety a key purchasing criterion by evaluating the system's built-in safety features, interlocks, and the manufacturer's commitment to providing comprehensive safety guidance.

Ultimately, integrating safety as a core operational value is what enables you to unlock the full potential of additive manufacturing without compromising the well-being of your team.

Summary Table:

| Hazard Category | Key Risks | Common Sources |

|---|---|---|

| Chemical | Inhalation toxicity, combustible dust, VOC emissions | Metal powders, polymer resins, solvents (e.g., IPA) |

| Physical | Eye/skin damage from lasers, burns from hot surfaces, radiation | Class 4 lasers, electron beams, heated build plates |

| Mechanical | Injury from moving parts, electric shock | Automated machinery, high-voltage electrical systems |

Safeguard your additive manufacturing process with KINTEK.

Navigating the complex hazards of AM—from toxic metal powders to high-energy lasers—requires expertise and the right equipment. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. We provide solutions for safe material handling, ventilation, and personal protection, helping you mitigate risks and ensure compliance.

Contact us today to discuss how we can support your safety protocols and enhance your operational efficiency. Let's build a safer manufacturing environment together.

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Double Plate Heating Press Mold for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- Why is laboratory stirring equipment essential in the Sol-Gel process? Achieving Chemical Homogeneity and Stability

- What is the application of pyrolysis in waste management? Unlock Waste into Energy & Resources

- What is the pyrolysis method of disposal? Transforming Waste into Valuable Resources

- What are the raw materials for biochar production? Choose the Right Feedstock for Your Goals

- What is pyrolysis in renewable energy? Converting Biomass and Methane into Clean Fuels

- Are single stage furnaces more reliable? Discover the truth about HVAC durability vs. comfort.

- How does a high-precision temperature control heating system ensure accurate corrosion kinetics? Expert Lab Solutions

- What causes increase in ash content? Uncover the hidden culprits that harm your equipment.