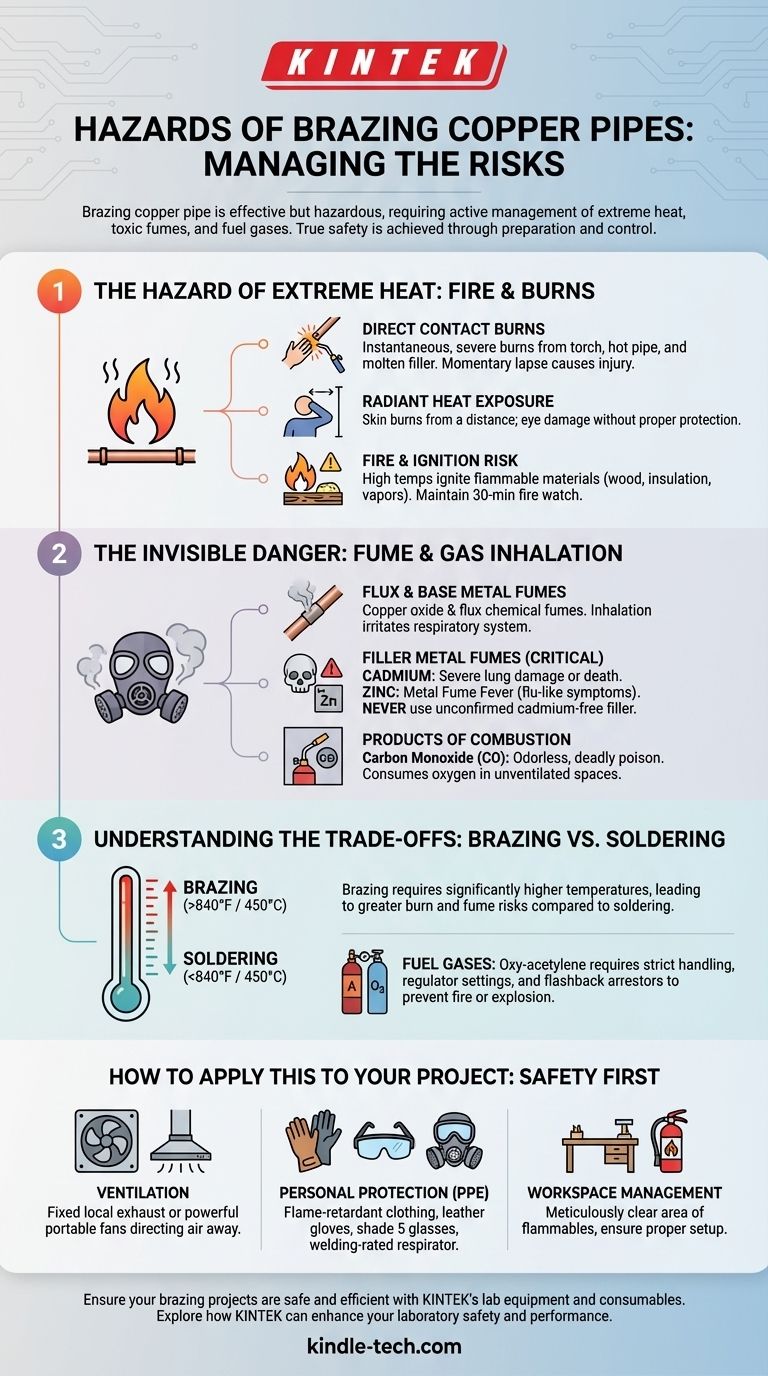

Brazing copper pipe is a highly effective joining method, but it comes with significant hazards that must be actively managed. The primary risks stem from the extreme heat required, which can cause severe burns and ignite nearby materials. In addition, the process generates toxic fumes from the flux, filler metals, and the copper itself, while the fuel gases used, such as acetylene, present a risk of fire or explosion if handled improperly.

The core hazards of brazing—fire, burns, and toxic fumes—are not unavoidable accidents, but predictable outcomes of inadequate preparation. True safety is achieved not by simply being aware of the dangers, but by systematically implementing controls for ventilation, personal protection, and workspace management.

The Hazard of Extreme Heat: Fire and Burns

Brazing requires heating copper pipes to temperatures well above 840°F (450°C), creating an environment of intense, concentrated heat. This energy is the source of the most immediate and obvious dangers.

Direct Contact Burns

The torch flame, the red-hot copper pipe, and the molten filler alloy can all cause instantaneous, severe burns upon contact. Even a momentary lapse in concentration can lead to a significant injury.

Radiant Heat Exposure

You do not need to touch a hot surface to be burned. The radiant heat emitted from the workpiece and torch can cause skin burns from a distance and is especially dangerous to the eyes without proper protection.

Fire and Ignition Risk

The high temperature of the flame and pipe can easily ignite flammable materials in the work area. This includes wood studs, insulation, paper, drywall, sawdust, and even vapors from solvents or cleaners. Always maintain a "fire watch" for at least 30 minutes after brazing is complete, as smoldering materials can ignite long after the flame is extinguished.

The Invisible Danger: Fume and Gas Inhalation

When materials are heated to brazing temperatures, they release a complex mixture of fumes and gases into the air. Without proper ventilation, these can accumulate to hazardous levels.

Fumes from Flux and Base Metals

Heating copper produces copper oxide fumes. The flux used to clean the metal also burns off, releasing its own chemical components into the air. Inhaling these can irritate the respiratory system.

Fumes from Filler Metals (Alloys)

This is a critical safety concern. Some older brazing alloys contain cadmium, an extremely toxic metal whose fumes can cause severe lung damage or death, often with delayed symptoms. Never use a filler metal if you cannot confirm it is cadmium-free.

Even "cadmium-free" alloys often contain zinc, which can cause metal fume fever. This condition produces flu-like symptoms such as fever, chills, and body aches, typically several hours after exposure.

Products of Combustion

Using a fuel-gas torch in an enclosed, unventilated space consumes oxygen and can produce carbon monoxide (CO). This odorless, colorless gas is a deadly poison that can quickly incapacitate an operator.

Understanding the Trade-offs: Brazing vs. Soldering Safety

While often confused, brazing and soldering have distinct safety profiles directly related to the temperatures involved.

Why Brazing is More Hazardous

Soldering is performed below 840°F (450°C), while brazing is performed above it. This higher temperature requirement for brazing means more thermal energy, a greater risk of severe burns, and a much higher rate of fume generation.

The Role of Fuel Gases

Soldering can often be done with a simple air-propane torch. Brazing, especially on larger pipes, frequently requires an oxy-acetylene setup. Acetylene is a more volatile and energetic fuel, demanding stricter handling procedures, proper regulator pressure settings, and the use of flashback arrestors to prevent the flame from traveling back into the hoses or cylinders.

How to Apply This to Your Project

A safe brazing operation is the direct result of a disciplined and well-informed operator. Your approach should be dictated by the context of your work.

- If your primary focus is professional, daily brazing: Your non-negotiable standard must include engineering controls like fixed local exhaust ventilation (fume extractors) and a strict, mandatory PPE policy that includes welding-rated respirators.

- If your primary focus is occasional repair or installation: Your primary tools are portable ventilation (powerful fans directing air away from you and out of the space) and a complete set of personal protective equipment (PPE), including a respirator, flame-retardant clothing, leather gloves, and shade 5 safety glasses.

- If you are considering a one-time project: Honestly assess if soldering, a lower-temperature and less hazardous process, can meet the technical requirements. If brazing is essential, invest fully in all recommended safety equipment and meticulously clear and prepare your work area before you begin.

Ultimately, mastering the safety procedures is as important as mastering the brazing technique itself.

Summary Table:

| Hazard Category | Specific Risks | Key Safety Measures |

|---|---|---|

| Extreme Heat | Severe burns, radiant heat exposure, ignition of flammable materials | Use flame-retardant clothing, shade 5 safety glasses, maintain fire watch |

| Toxic Fumes | Copper oxide, flux chemicals, cadmium/zinc fumes (metal fume fever), carbon monoxide | Ensure proper ventilation, use welding-rated respirators, confirm cadmium-free alloys |

| Fuel Gases | Fire/explosion risk from acetylene, oxygen depletion | Use flashback arrestors, check regulator settings, work in well-ventilated areas |

Ensure your brazing projects are safe and efficient with KINTEK's lab equipment and consumables. Whether you're a professional handling daily brazing or tackling a one-time project, our specialized tools support proper ventilation, fume extraction, and personal protection. Contact us today to explore how KINTEK can enhance your laboratory safety and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is oxidation in brazing? How to prevent it for strong, durable joints

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing