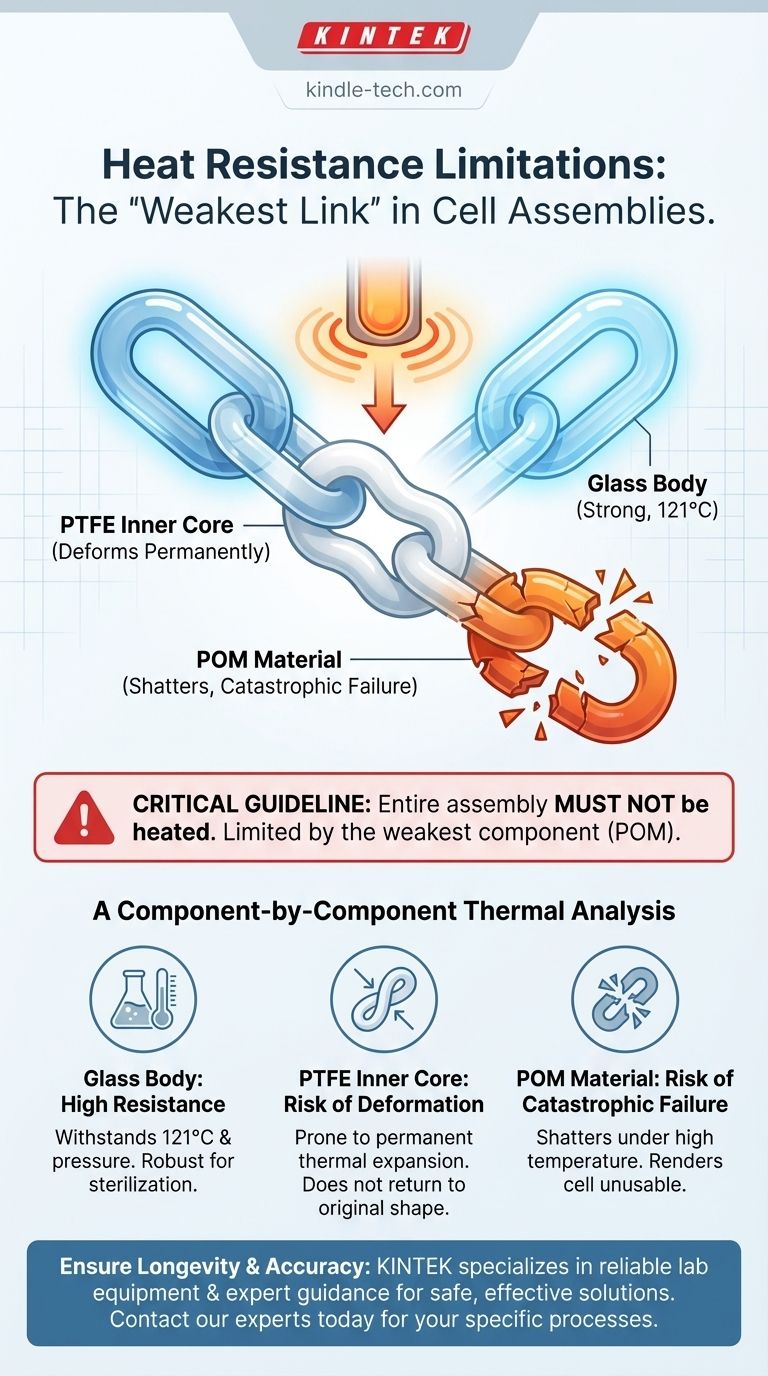

While the glass body of the cell is highly durable, the heat resistance of the entire assembly is severely limited by its internal components. The polytetrafluoroethylene (PTFE) inner core will deform permanently and the POM material will shatter if heated. Therefore, the complete, assembled cell must not be subjected to high-temperature sterilization, even though the glass itself can withstand 121°C.

The operational heat limit of a multi-component assembly is not defined by its strongest part, but by its weakest. In this case, the internal plastics dictate the thermal tolerance for the entire unit, making high-temperature applications unsafe.

A Component-by-Component Thermal Analysis

To understand the cell's limitations, we must assess each material's response to heat individually.

The Glass Body: High Resistance

The external glass body is robust. It is designed to withstand both high temperature and high pressure, specifically for sterilization procedures at 121°C.

The PTFE Inner Core: The Risk of Deformation

The inner core is made of polytetrafluoroethylene (PTFE), a fluoropolymer known for its chemical resistance. However, when heated, it is prone to thermal expansion.

Crucially, this expansion may be permanent. The component will not return to its original shape and size upon cooling, which can compromise seals and internal geometry.

The POM Material: The Risk of Catastrophic Failure

Another critical internal component is made of POM (Polyoxymethylene), a common engineering thermoplastic. This material has a low tolerance for heat.

When subjected to high temperatures, POM does not bend or deform—it shatters. This is a catastrophic failure that will render the entire cell unusable.

Understanding the Critical Limitation

The core issue is that the cell functions as an integrated system. The failure of any single component results in the failure of the entire assembly.

The "Weakest Link" Principle

The overall thermal resistance of the cell is dictated by its most heat-sensitive material, which is the POM. Even though the glass can handle the heat, the internal components cannot.

The Consequence of Overheating

Attempting to heat-sterilize the assembled cell will lead to irreversible damage. The shattering of the POM and deformation of the PTFE will destroy the unit's integrity and function.

The Official Guideline

Because of these material limitations, the manufacturer's directive is explicit: the entire assembly must not be heated or subjected to high-temperature sterilization.

Common Pitfalls to Avoid

Misunderstanding these material properties can lead to costly errors.

Assuming the Glass Casing Defines the Limit

The most common mistake is assuming that because the main body is glass, the entire unit is autoclavable. This overlooks the critical, less-visible internal components.

Attempting Partial Heating

Applying heat to only one part of the assembly is also dangerous. Heat transfers through the materials and can still cause the internal plastic components to reach their failure temperature.

How to Apply This Knowledge Safely

Your approach must respect the limitations of the most sensitive materials in the assembly.

- If your primary focus is sterilization: You must use a non-thermal method, such as chemical sterilization, compatible with glass, PTFE, and POM.

- If your primary focus is experimental use: You must ensure that your operational processes do not cause the assembly's temperature to rise to a level that threatens the internal components.

- If you are ever in doubt: Default to the most conservative approach and do not apply heat to the assembled unit under any circumstances.

Ultimately, treating the cell as a complete system, rather than a collection of individual parts, is the key to its safe and effective operation.

Summary Table:

| Component | Material | Heat Response & Limitation |

|---|---|---|

| Glass Body | Glass | Withstands 121°C; robust for sterilization. |

| Inner Core | PTFE (Polytetrafluoroethylene) | Deforms permanently with heat; does not return to shape. |

| Internal Parts | POM (Polyoxymethylene) | Shatters under high temperature; catastrophic failure. |

| Complete Assembly | Multi-material | Must not be heated; limited by weakest link (POM). |

Ensure the longevity and accuracy of your experiments. The thermal limitations of complex lab equipment are critical. KINTEK specializes in providing reliable lab equipment and consumables, with expert guidance to help you select and use the right tools for your specific processes, including heat-sensitive applications. Contact our experts today to find safe, effective solutions for your laboratory needs.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- High Temperature Resistant Optical Quartz Glass Sheet

- Nickel Foam for Industrial and Laboratory Applications

People Also Ask

- How should an appropriate PTFE cleaning basket be selected? A Guide to Efficient and Safe Lab Cleaning

- What is the function of a customized PTFE cap in IL-TEM? Bridge the Gap Between Microscopy and Electrochemistry

- What inspection should be performed on a PTFE cleaning basket before use? A 3-Step Protocol for Safe, Effective Cleaning

- What maintenance procedures are recommended for a PTFE cleaning basket? Extend Equipment Life & Ensure Process Purity

- How should a PTFE cleaning basket be cleaned before its initial use? A Critical First Step for Process Integrity