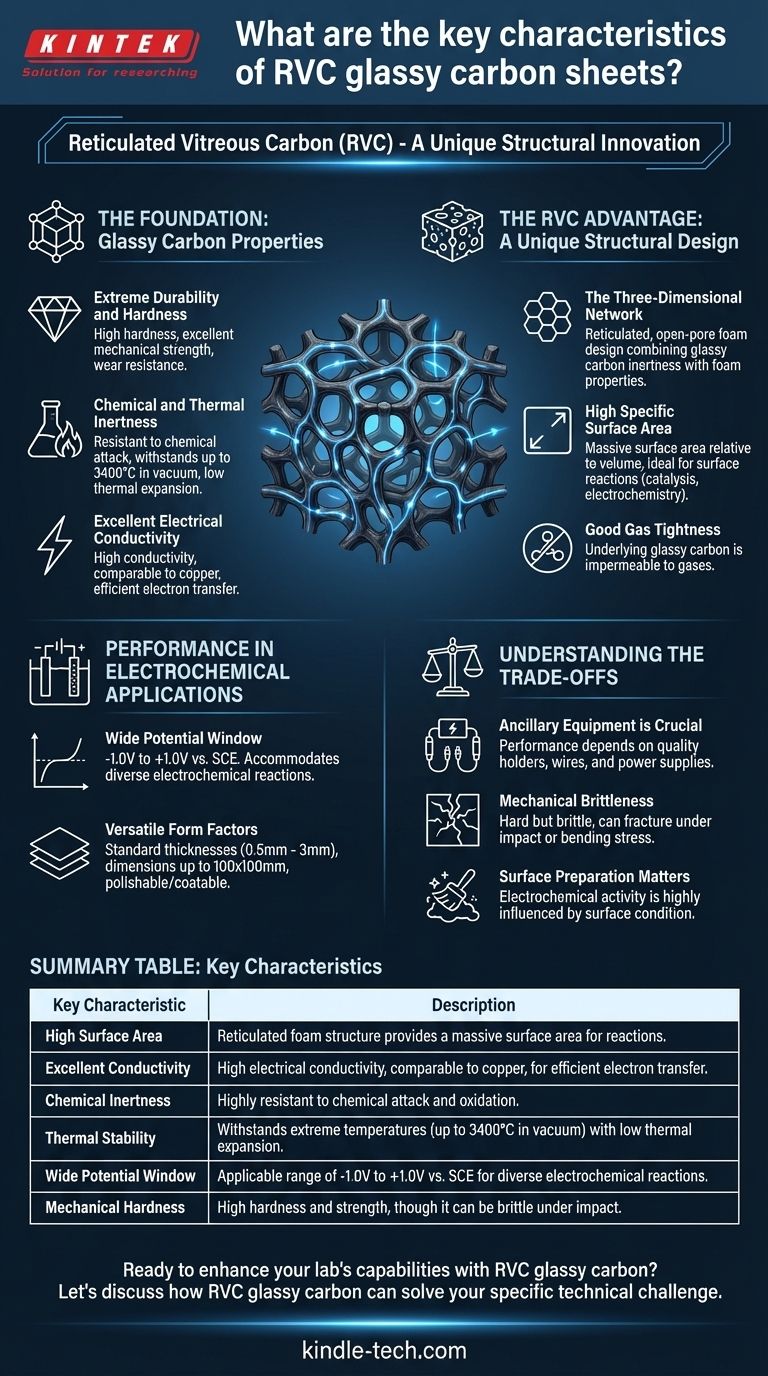

Reticulated Vitreous Carbon (RVC) glassy carbon sheets are a specialized material defined by a unique combination of properties derived from their structure. They possess high chemical stability, excellent electrical conductivity, a large specific surface area, and significant mechanical hardness, all stemming from their three-dimensional, foam-like carbon network.

RVC glassy carbon is not just a material; it's a structural innovation. By forming amorphous glassy carbon into a porous, reticulated network, it delivers the robust chemical and electrical properties of solid carbon in a high-surface-area format ideal for advanced electrochemical and high-temperature applications.

The Foundation: Glassy Carbon Properties

Before understanding the unique RVC structure, it's crucial to grasp the characteristics of its base material, glassy carbon. This amorphous form of carbon provides the fundamental durability and performance.

### Extreme Durability and Hardness

Glassy carbon exhibits high hardness, approaching that of a diamond. This translates to excellent mechanical strength and resistance to wear in many applications.

### Chemical and Thermal Inertness

The material is highly resistant to chemical attack and oxidation. It can also withstand extreme temperatures, up to 3400°C in a vacuum, and has a very low coefficient of thermal expansion, preventing it from deforming under thermal stress.

### Excellent Electrical Conductivity

Its electrical conductivity is notably high, often compared to that of copper. This makes it an effective material for applications requiring efficient electron transfer, such as electrodes.

The RVC Advantage: A Unique Structural Design

The defining feature of RVC is its structure. It is produced by the high-temperature carbonization of a polymer foam, creating a material that is both porous and robust.

### The Three-Dimensional Network

This process results in a reticulated, or net-like, three-dimensional structure. This open-pore foam design combines the inertness of glassy carbon with the physical properties of a foam.

### High Specific Surface Area

The primary benefit of this foam-like structure is an exceptionally large surface area relative to its volume. This is a critical advantage for applications involving surface reactions, such as catalysis and electrochemistry.

### Good Gas Tightness

Despite its porous appearance, the underlying glassy carbon material is impermeable to gases, a property known as good gas tightness.

Performance in Electrochemical Applications

The combination of these properties makes RVC glassy carbon a premier material for electrochemical experiments and devices.

### Wide Potential Window

RVC offers a wide applicable potential range, approximately -1.0V to +1.0V relative to a saturated calomel electrode (SCE). This window accommodates a vast number of different electrochemical reactions without the electrode material itself degrading.

### Versatile Form Factors

These sheets are available in standard thicknesses (0.5mm to 3mm) and dimensions (up to 100x100mm). The surface can also be polished, roughened, or coated to meet specific experimental needs.

Understanding the Trade-offs

While powerful, RVC glassy carbon is not a universal solution. Understanding its practical limitations is key to successful implementation.

### Ancillary Equipment is Crucial

The performance of an RVC electrode is highly dependent on the quality of the surrounding setup. Using properly matched electrode holders, wires, and power supplies is essential for collecting accurate and reliable data.

### Mechanical Brittleness

Like many extremely hard materials, glassy carbon can be brittle. It can withstand high compressive force but may fracture under sharp impact or significant bending stress.

### Surface Preparation Matters

The electrochemical activity of RVC can be heavily influenced by its surface condition. Ensuring the surface is clean and prepared appropriately for the intended experiment is a critical step that cannot be overlooked.

Making the Right Choice for Your Goal

To apply this material effectively, align its key strengths with your primary objective.

- If your primary focus is electrochemical analysis: The combination of a wide potential window, high conductivity, and massive surface area makes it an ideal electrode material.

- If your primary focus is high-temperature filtration or catalysis: Its chemical inertness, thermal stability, and porous structure offer a durable and effective solution.

- If your primary focus is a lightweight, conductive structural component: Its mechanical strength and low density provide a unique advantage over traditional materials in specific environments.

Ultimately, understanding these core characteristics allows you to leverage the unique structural and chemical advantages of RVC glassy carbon for your specific technical challenge.

Summary Table:

| Key Characteristic | Description |

|---|---|

| High Surface Area | Reticulated foam structure provides a massive surface area for reactions. |

| Excellent Conductivity | High electrical conductivity, comparable to copper, for efficient electron transfer. |

| Chemical Inertness | Highly resistant to chemical attack and oxidation. |

| Thermal Stability | Withstands extreme temperatures (up to 3400°C in vacuum) with low thermal expansion. |

| Wide Potential Window | Applicable range of -1.0V to +1.0V vs. SCE for diverse electrochemical reactions. |

| Mechanical Hardness | High hardness and strength, though it can be brittle under impact. |

Ready to enhance your lab's capabilities with RVC glassy carbon?

As a specialist in high-performance lab equipment, KINTEK provides the materials and expertise to power your most demanding electrochemical, catalytic, and high-temperature applications. Our RVC glassy carbon sheets are designed for researchers and engineers who require unparalleled chemical stability, conductivity, and surface area.

Let's discuss how RVC glassy carbon can solve your specific technical challenge. Contact our experts today for a consultation!

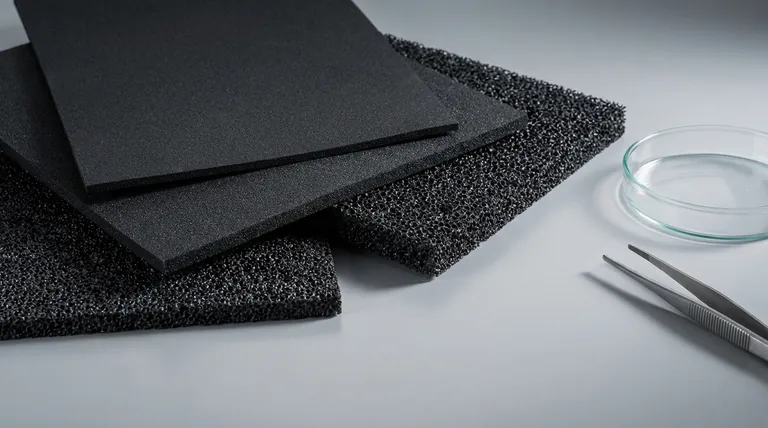

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What are the materials used for the components of the PTFE electrode stand? A Guide to Chemical Resistance & Stability

- What is the critical rule for using a gold plate electrode? Ensure Only the Gold Surface Contacts the Electrolyte

- What is an example of an electrode? The Bridge Between Power and Performance

- Why is a Saturated Calomel Electrode (SCE) required for bioelectrochemical systems? Ensure Precise Potential Control

- What is the purpose of Ag/AgCl reference electrodes for Zr2.5Nb alloys? Ensure Precision in Corrosion Testing

- What is the purity of the platinum used in the platinum mesh electrode? Ensuring 99.99% Purity for Reliable Results

- Why is a platinum wire electrode considered an essential consumable? Ensure Purity in Electrochemical Characterization

- Why are Ruthenium-Titanium MMO electrodes preferred for chlorate production? Optimize Efficiency & Durability