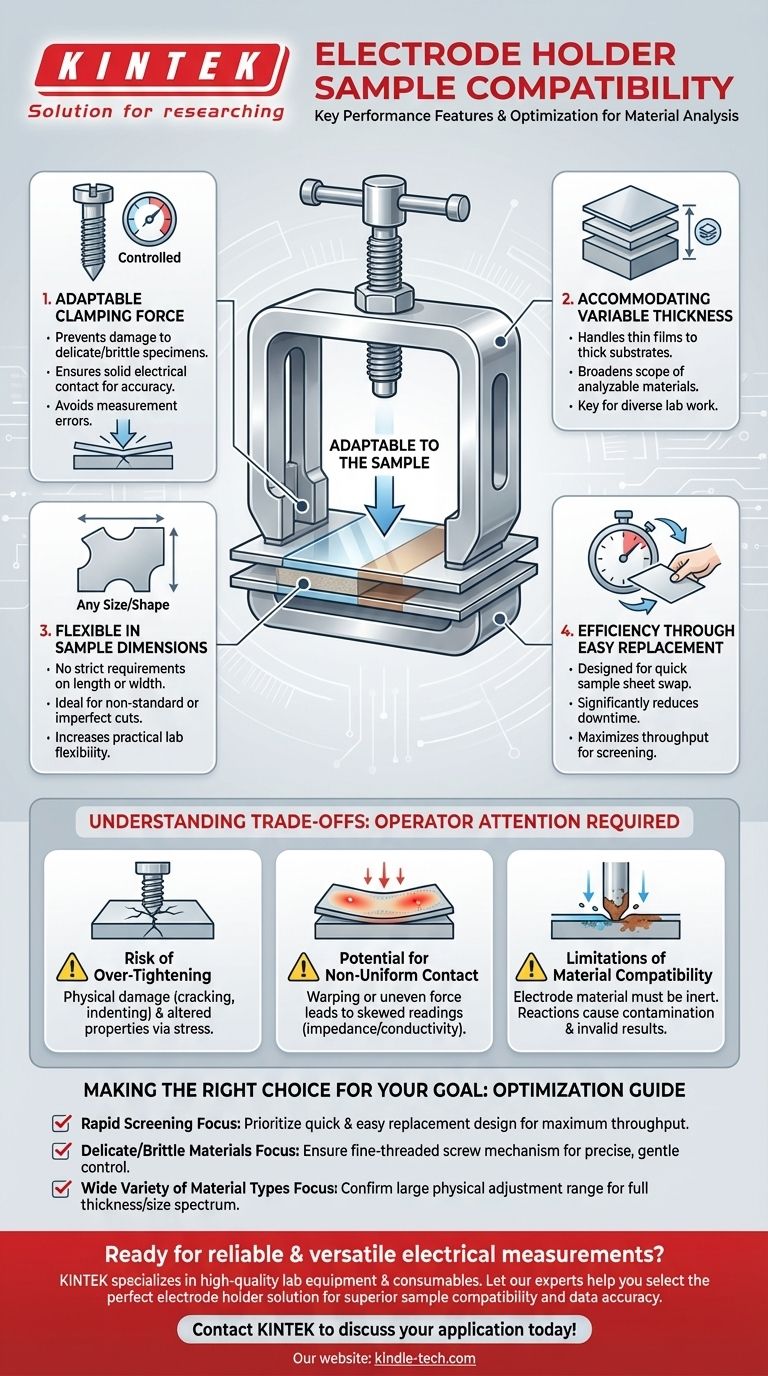

The key performance features of an electrode holder regarding sample compatibility are its mechanical adjustability and operational flexibility. This is primarily achieved through an adjustable clamping mechanism that accommodates various sample thicknesses and the overall design, which allows for easy replacement of different sample sizes without strict dimensional requirements.

The true value of a well-designed electrode holder is its ability to provide a stable, repeatable, and non-destructive electrical connection for a wide range of materials. This adaptability is the foundation for ensuring the integrity of your measurements, regardless of the specimen's physical form.

The Core Principles of Sample Compatibility

To understand how an electrode holder performs, we must look at the features that allow it to adapt to diverse samples. These principles ensure that the holder is a versatile tool rather than a limiting factor in your experimental setup.

Adaptable Clamping Force

The most critical feature is the ability to control the clamping force, often managed by a simple screw mechanism.

This allows the user to apply just enough pressure to ensure a solid electrical contact between the electrode and the sample surface. This prevents measurement errors from poor contact while avoiding damage to delicate or brittle specimens.

Accommodating Variable Thickness

Versatile electrode holders are engineered to accept samples of vastly different thicknesses, from thin films to thicker substrates.

This feature is fundamental to performance, as it broadens the scope of materials and preparation methods that can be analyzed with a single piece of equipment.

Flexibility in Sample Dimensions

The holder’s design intentionally avoids strict requirements for the sample's length or width.

This flexibility is crucial for practical lab work, where specimens may not be perfectly uniform or may be cut to non-standard sizes for specific experimental reasons.

Efficiency Through Easy Replacement

A key performance metric in any testing environment is throughput. The holder is designed for the easy replacement of sample sheets.

This significantly reduces downtime between measurements, allowing for more efficient screening of multiple samples and improving overall lab productivity.

Understanding the Trade-offs

While versatility is a primary goal, the design of a universal electrode holder comes with inherent trade-offs that require operator attention to ensure accurate results.

The Risk of Over-Tightening

The manual screw mechanism, while providing control, also introduces the potential for human error.

Over-tightening can physically damage the sample by cracking or indenting it. More subtly, it can alter the material's intrinsic properties through mechanical stress, leading to inaccurate electrical measurements.

Potential for Non-Uniform Contact

Achieving perfectly uniform contact pressure across the entire electrode-sample interface can be challenging.

If a sample is slightly warped or the force is not applied perfectly evenly, it can create areas of poor contact. This leads to non-uniform current distribution, which can skew impedance or conductivity readings.

Limitations of Material Compatibility

The compatibility discussion must also include the holder's own materials.

The electrodes themselves must be made of a conductive and chemically inert material that will not react with the sample being tested. Any reaction can contaminate the sample or create an unintended interfacial layer, invalidating the results.

Making the Right Choice for Your Goal

The ideal electrode holder setup depends entirely on your specific experimental priorities. By understanding the holder's features and limitations, you can optimize your procedure.

- If your primary focus is rapid screening of many samples: Prioritize a holder explicitly designed for quick and easy sample replacement to maximize your throughput.

- If your primary focus is testing delicate or brittle materials: Ensure the holder has a fine-threaded screw mechanism for precise, gentle control over clamping force to prevent sample damage.

- If your primary focus is testing a wide variety of material types: Confirm that the holder's physical adjustment range can accommodate the full spectrum of thicknesses and sizes you plan to analyze.

Ultimately, an effective electrode holder empowers reliable and flexible material analysis by adapting to the sample, not the other way around.

Summary Table:

| Key Feature | Impact on Sample Compatibility |

|---|---|

| Adjustable Clamping Force | Prevents damage to delicate samples while ensuring solid electrical contact. |

| Variable Thickness Range | Accommodates samples from thin films to thicker substrates. |

| Flexible Sample Dimensions | Allows for analysis of non-standard or imperfectly cut specimens. |

| Easy Sample Replacement | Increases lab throughput by minimizing downtime between tests. |

Ready to achieve reliable and versatile electrical measurements for your unique samples? The right electrode holder is critical for protecting sample integrity and ensuring data accuracy. KINTEK specializes in high-quality lab equipment and consumables, including electrode holders designed for superior sample compatibility and ease of use. Let our experts help you select the perfect solution for your material analysis needs. Contact KINTEK today to discuss your application and optimize your testing process!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Button Battery Case for Battery Lab Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool