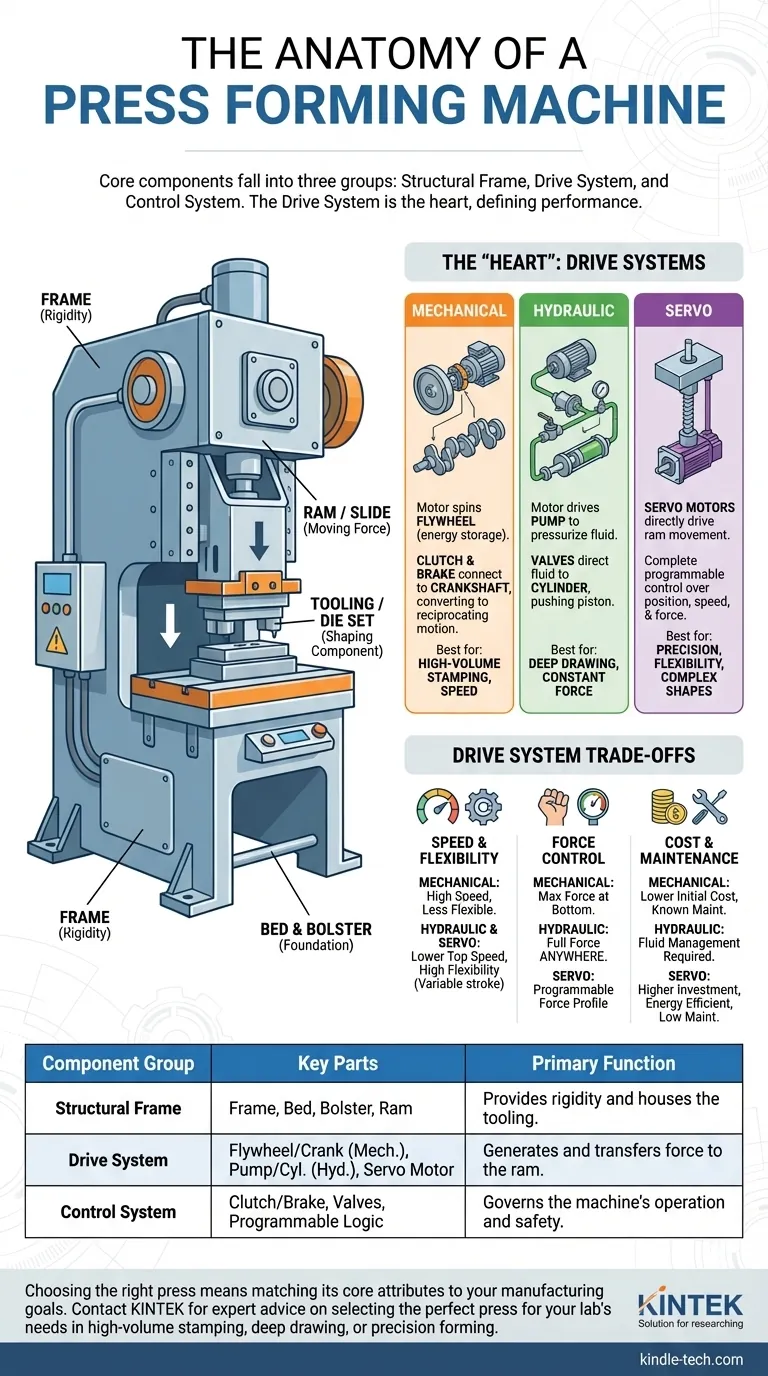

At its core, a press forming machine consists of three fundamental groups of components. These are the structural frame that provides rigidity, the drive system that generates force, and the control system that governs the machine's operation. While the specific parts vary by press type, this functional anatomy is universal.

Understanding a press isn't just about listing its parts; it's about recognizing that the drive system—whether mechanical, hydraulic, or servo—is the single most important factor that defines the machine's performance, capabilities, and ideal application.

The Universal Anatomy of a Press

All press forming machines, regardless of how they are powered, are built on a common set of structural components that hold the tooling and absorb the immense forces of forming.

The Frame: The Machine's Backbone

The frame is the main structure of the press, designed for maximum rigidity to resist deflection under load. The frame's design is a primary differentiator, typically falling into one of two categories: C-frame (or gap frame) for accessibility or straight-side for the highest levels of precision and tonnage.

The Bed and Bolster: The Foundation for Work

The bed is the stationary lower surface of the press. A bolster plate is almost always mounted to the bed, providing a standardized surface with T-slots or tapped holes for mounting the lower portion of the die set.

The Ram (or Slide): The Moving Force

The ram, also known as the slide, is the moving component of the press that travels up and down. It houses the upper portion of the die set and is responsible for transferring the force generated by the drive system directly to the workpiece.

The Tooling (Die Set): The Shaping Component

While technically separate from the press itself, the tooling or die set is the essential component that performs the actual shaping. It consists of an upper and lower die that, when brought together by the ram's force, cut, bend, or form the material into the desired shape.

The "Heart" of the Press: The Drive System

The drive system is what generates the motion and force of the ram. The technology used here is the primary way presses are classified and is the source of their distinct performance characteristics.

Mechanical Presses

A mechanical press uses a motor to spin a large, heavy flywheel, which stores rotational energy. When activated, a clutch and brake system connects the flywheel to a crankshaft (or eccentric gear), converting the rotational energy into the reciprocating vertical motion of the ram.

Hydraulic Presses

A hydraulic press, as the name implies, uses a fluid-based system. An electric motor drives a hydraulic pump, which pressurizes fluid (typically oil). Valves direct this high-pressure fluid into a large cylinder, pushing a piston connected to the ram downwards to generate force.

Servo Presses

A servo press is a more modern evolution that replaces the conventional flywheel and clutch with high-torque servo motors. These motors directly drive the ram's movement, often through a ballscrew or other mechanical linkage, allowing for complete and programmable control over the ram's position, speed, and force throughout the entire stroke.

Understanding the Trade-offs: Choosing Your Drive System

No single press type is superior for all applications. The choice involves a direct trade-off between speed, flexibility, and cost.

Speed vs. Flexibility

Mechanical presses are champions of speed, capable of high stroke rates, making them ideal for high-volume stamping. Hydraulic and servo presses trade some of this top-end speed for incredible flexibility, allowing for variable stroke lengths and speeds.

Force Control and Application

A mechanical press delivers its maximum force only at the very bottom of its stroke. In contrast, a hydraulic press can deliver its full rated force at any point in the stroke, making it perfect for deep-drawing operations that require sustained pressure. Servo presses offer the ultimate control, allowing the force profile to be programmed throughout the stroke.

Cost and Maintenance

Mechanical presses often have a lower initial cost and well-understood maintenance routines. Hydraulic presses require diligent fluid management to prevent leaks and contamination. Servo presses represent the highest initial investment but offer significant long-term benefits in energy efficiency and reduced changeover time.

Making the Right Choice for Your Goal

Selecting the correct press requires matching its core attributes to your primary manufacturing objective.

- If your primary focus is high-volume, simple stamping: A mechanical press offers the best combination of speed and cost-efficiency for producing large quantities of parts.

- If your primary focus is deep drawing or forming complex shapes: A hydraulic press provides the constant, controllable force needed to successfully form parts without tearing or wrinkling.

- If your primary focus is ultimate precision and process control: A servo press delivers unmatched programmability, making it ideal for forming exotic materials or for applications demanding absolute repeatability.

Ultimately, understanding these core components empowers you to look beyond the machine's tonnage and see the system that will best achieve your manufacturing goals.

Summary Table:

| Component Group | Key Parts | Primary Function |

|---|---|---|

| Structural Frame | Frame, Bed, Bolster, Ram | Provides rigidity and houses the tooling. |

| Drive System | Flywheel & Crankshaft (Mechanical), Pump & Cylinder (Hydraulic), Servo Motor (Servo) | Generates and transfers force to the ram. |

| Control System | Clutch/Brake, Valves, Programmable Logic | Governs the machine's operation and safety. |

Struggling to choose the right press for your specific forming needs? The drive system is the heart of the machine and defines its performance. KINTEK specializes in lab equipment and consumables, serving laboratory needs for material testing and sample preparation. Our experts can help you select the perfect press—whether mechanical, hydraulic, or servo—to achieve your goals in high-volume stamping, deep drawing, or precision forming. Contact our team today for a personalized consultation and discover how the right press can enhance your lab's efficiency and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity