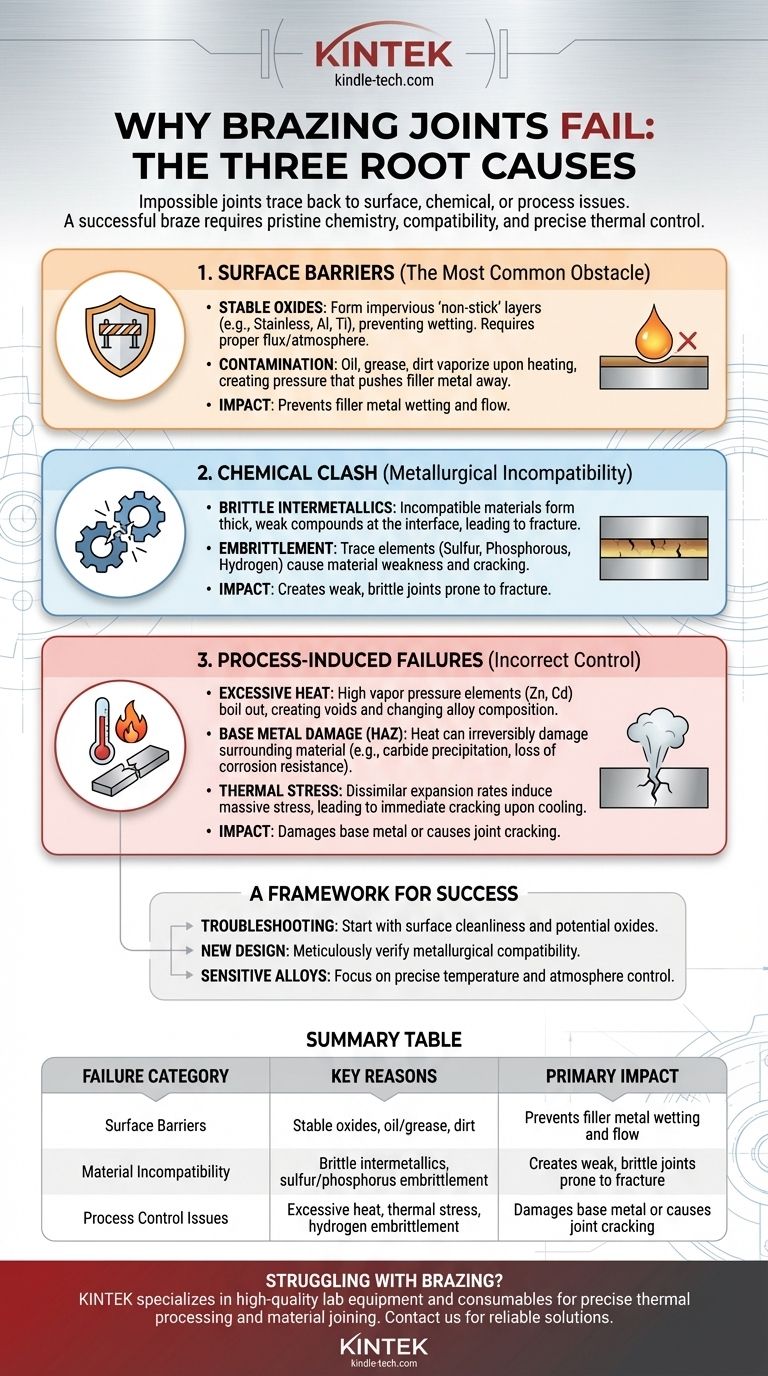

When a braze joint is impossible to form, the root cause almost always traces back to one of three areas: surface contamination, chemical incompatibility between materials, or incorrect process control. If the molten filler metal cannot wet and flow into the joint via capillary action, or if it reacts with the base metal to form a brittle compound, a sound connection cannot be made.

A successful braze depends on a triad of ideal conditions: pristine surface chemistry, metallurgical compatibility, and precise thermal management. Failure in any one of these areas can make a joint impossible to create, not because of a single flaw, but because the fundamental principles of adhesion and alloying have been violated.

The Primary Obstacle: Surface Barriers

The most common reason for a braze to fail is the inability of the filler metal to make intimate contact with the base metals. This is almost always a surface-level problem.

The Challenge of Stable Oxides

Many metals, particularly stainless steel, aluminum, and titanium, instantly form a thin but highly stable and impervious layer of oxide on their surface. This oxide layer acts like a non-stick coating, preventing the molten filler metal from wetting the surface and flowing into the joint. A proper flux or controlled atmosphere is required to remove these oxides during heating.

Contamination and Improper Cleaning

Beyond natural oxides, any surface contaminant like oil, grease, dirt, or even markings from a pen will vaporize during heating. This outgassing creates pressure that actively pushes the filler metal away from the joint, making a bond physically impossible.

When Base and Filler Metals Chemically Clash

Even with a perfectly clean surface, the wrong combination of materials can lead to a joint that is brittle, weak, or simply fails to form. These are deeper metallurgical issues.

Destructive Alloying and Intermetallics

Brazing works by the filler metal alloying slightly with the base metal. However, if the materials are incompatible, they can form thick, brittle intermetallic compounds at the interface. This brittle layer will easily fracture under minimal stress, destroying the integrity of the joint.

Embrittlement from Trace Elements

Certain elements, even in trace amounts, can be catastrophic. Sulfur embrittlement can occur when brazing nickel alloys that have been contaminated with sulfur-bearing compounds. Likewise, phosphorous embrittlement can weaken certain steel and nickel alloys if a phosphorus-bearing filler is used improperly.

The Problem of Hydrogen

Hydrogen embrittlement is a significant risk for high-strength steels. At brazing temperatures, hydrogen (from the atmosphere or flux) can be absorbed by the metal, causing it to become extremely brittle and prone to cracking after it cools.

Understanding the Trade-offs: Process-Induced Failures

The brazing process itself—specifically how heat is applied and controlled—can create conditions that make a sound joint impossible.

Excessive Heat and High Vapor Pressure

Some filler metals contain elements with low boiling points, such as zinc and cadmium. If the joint is overheated, these elements can boil out of the filler metal. This not only creates voids in the joint but also fundamentally changes the chemical composition and performance of the remaining filler alloy. This effect is driven by the material's vapor pressure.

Damaging the Base Metal (Heat-Affected Zone)

The heat required for brazing can irreversibly damage the base metal in the area surrounding the joint, known as the heat-affected zone (HAZ). For example, in some stainless steels, heating can cause carbide precipitation, which depletes the material's corrosion resistance and can make it brittle.

Thermal Stress and Cracking

When joining dissimilar metals, their different rates of thermal expansion can induce massive stress in the joint as it cools. If this stress exceeds the strength of the base or filler metal at temperature, it can lead to immediate stress cracking, pulling the joint apart before it is even complete.

A Framework for Successful Brazing

To avoid these failures, your approach must be proactive, focusing on material selection and process control from the outset.

- If you are troubleshooting a failed joint: Start by investigating surface cleanliness and the potential for stable oxides, as these are the most frequent and fundamental barriers.

- If you are designing a new application: Meticulously verify the metallurgical compatibility between your base metals and the proposed filler metal to prevent the formation of brittle intermetallics.

- If you are working with sensitive or high-strength alloys: Your primary focus must be on precise temperature and atmosphere control to prevent damage to the base metal and avoid embrittlement.

By understanding these core principles, you can transform brazing from a challenging process into a predictable and highly reliable joining technology.

Summary Table:

| Failure Category | Key Reasons | Primary Impact |

|---|---|---|

| Surface Barriers | Stable oxides, oil/grease, dirt | Prevents filler metal wetting and flow |

| Material Incompatibility | Brittle intermetallics, sulfur/phosphorus embrittlement | Creates weak, brittle joints prone to fracture |

| Process Control Issues | Excessive heat, thermal stress, hydrogen embrittlement | Damages base metal or causes joint cracking |

Struggling with unreliable brazed joints? KINTEK specializes in providing the high-quality lab equipment and consumables necessary for precise thermal processing and material joining. Our expertise ensures you have the right tools to achieve clean surfaces, controlled atmospheres, and perfect temperatures for successful brazing every time. Contact us today (#ContactForm) to discuss how we can support your laboratory's specific needs and enhance your joining process reliability.

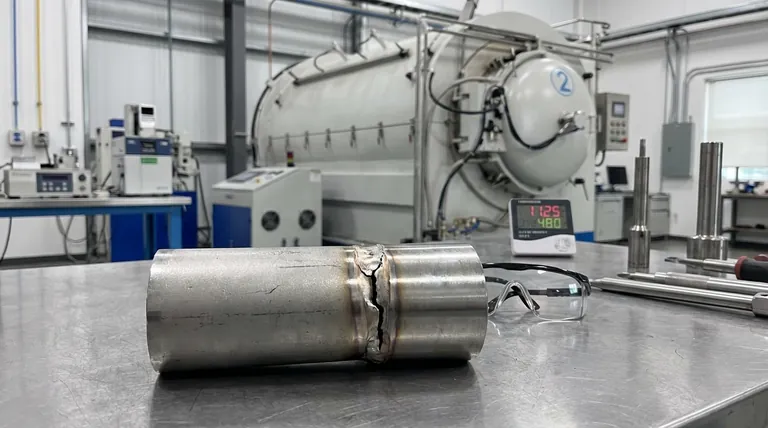

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does molybdenum increase corrosion resistance? Strengthen Alloy Durability Against Pitting & Chlorides

- What is a plasma furnace? Harness Ultra-High Temperatures for Extreme Material Processing

- Do diamond testing machines work? Choose the Right Tester for Accurate Results

- What are the feedstocks for biochar production? Choose the Right Material for Your Application

- What is sintering of powdered metals and ceramics? The Key to Creating Dense, High-Performance Parts

- What are the limitations of magnetron sputtering? Key Trade-offs in Thin Film Deposition

- How long does it take to heat treat steel? From Hours to Days, Depending on Your Goal

- What is plasma in the context of materials science? Understanding Its Role as a Versatile Material Processing Tool