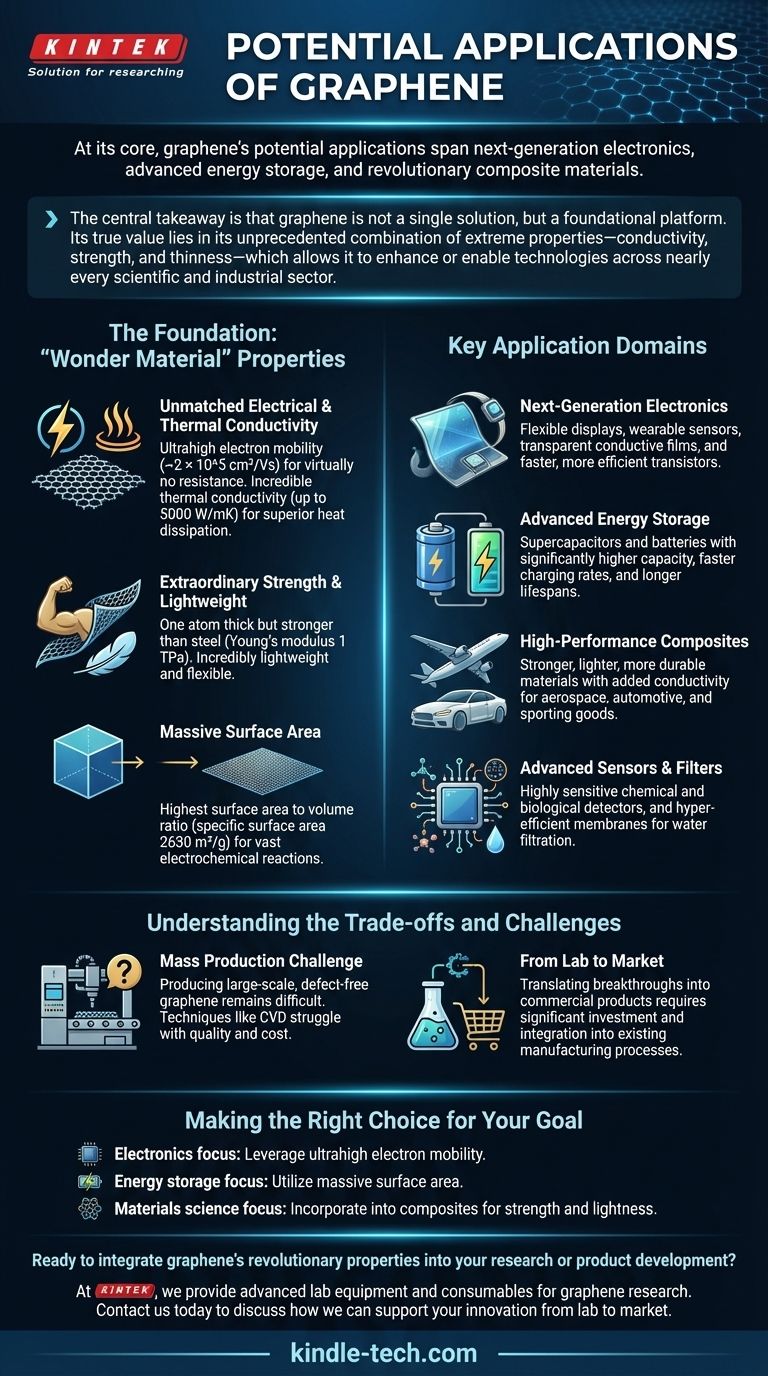

At its core, graphene's potential applications span next-generation electronics, advanced energy storage, and revolutionary composite materials. Its unique structure—a single layer of carbon atoms in a honeycomb lattice—makes it the strongest, thinnest, and most conductive material ever discovered, enabling uses from flexible touchscreens and ultra-efficient batteries to stronger, lighter plastics and membranes.

The central takeaway is that graphene is not a single solution, but a foundational platform. Its true value lies in its unprecedented combination of extreme properties—conductivity, strength, and thinness—which allows it to enhance or enable technologies across nearly every scientific and industrial sector.

The Foundation: Why Graphene is a "Wonder Material"

To understand graphene's applications, you must first understand its fundamental properties. These are not just incremental improvements; they are orders of magnitude beyond conventional materials, which is why it earned the Nobel Prize in Physics.

Unmatched Electrical and Thermal Conductivity

Graphene possesses an exceptionally high electron mobility (~2 × 10^5 cm²/Vs), meaning electrons can move through it with virtually no resistance. This is the bedrock of its potential in electronics.

Simultaneously, it has an incredible thermal conductivity (up to 5000 W/mK), allowing it to dissipate heat far more effectively than copper or silicon.

Extraordinary Strength and Lightweight Nature

Despite being only one atom thick, a sheet of defect-free graphene is stronger than steel, with a Young's modulus of 1 TPa.

This immense strength is packed into a material that is also incredibly lightweight and flexible, a combination rarely seen in nature or engineering.

A Massive Surface Area in a Minimal Volume

Graphene has the highest surface area to volume ratio of any material, with a theoretical specific surface area of 2630 m²/g.

This property is the key to its application in energy storage, as it provides a vast area for electrochemical reactions to occur.

Key Application Domains in Practice

These fundamental properties translate directly into practical, high-impact applications that are currently in development or early commercialization.

Next-Generation Electronics

Graphene's high electron mobility and transparency make it a prime candidate for flexible displays, wearable sensors, and transparent conductive films.

Its conductivity could also lead to faster and more efficient transistors, pushing beyond the limits of current silicon-based technology.

Advanced Energy Storage

The enormous surface area of graphene allows for the creation of supercapacitors and batteries that can store significantly more energy and charge much faster than current lithium-ion technology.

By incorporating graphene into battery electrodes, manufacturers can improve capacity, lifespan, and charging speed.

High-Performance Composites

When mixed with polymers, metals, or other materials, graphene creates composites with dramatically enhanced properties.

These materials can be made significantly stronger, more durable, and lighter, with the added ability to conduct heat or electricity. This is invaluable for the aerospace, automotive, and sporting goods industries.

Advanced Sensors and Filters

Because it is a two-dimensional sheet, every single atom in graphene is exposed to its environment. This makes it an incredibly sensitive material for detecting chemical and biological agents.

Its atomic thinness and strength also allow it to be used as a hyper-efficient membrane for water filtration or other separation processes.

Understanding the Trade-offs and Challenges

While graphene's potential is immense, its widespread adoption faces significant practical hurdles that are critical to understand.

The Challenge of Mass Production

Producing pristine, defect-free graphene on a large scale remains a major challenge. Methods like mechanical exfoliation produce high-quality flakes but are not scalable.

Techniques like Chemical Vapour Deposition (CVD) can create large sheets, but controlling quality and cost is a persistent engineering problem. The properties of mass-produced graphene often fall short of the theoretical ideal.

From Lab to Market

Translating laboratory breakthroughs into reliable, cost-effective commercial products is the primary bottleneck. Integrating graphene into existing manufacturing processes requires significant research and investment.

Many of graphene's most revolutionary applications are still in the research and development phase, and it will take time to overcome the technical and economic barriers to commercialization.

Making the Right Choice for Your Goal

Understanding which of graphene's properties aligns with your objective is key to evaluating its potential for any given project.

- If your primary focus is electronics and computing: Graphene's ultrahigh electron mobility offers a path toward faster, more efficient transistors and transparent, flexible devices.

- If your primary focus is energy storage: Its immense surface area is the key to developing batteries and supercapacitors with higher capacity and faster charging rates.

- If your primary focus is materials science and engineering: Incorporating graphene into composites can create materials that are simultaneously stronger, lighter, and more functionally conductive.

Ultimately, graphene's future lies in leveraging its unique combination of properties to solve specific, high-value problems that are impossible to address with conventional materials.

Summary Table:

| Application Domain | Key Graphene Property | Potential Impact |

|---|---|---|

| Next-Gen Electronics | Ultra-high electron mobility, transparency | Flexible displays, faster transistors, wearable sensors |

| Advanced Energy Storage | Massive surface area (2630 m²/g) | Faster-charging, higher-capacity batteries & supercapacitors |

| High-Performance Composites | Exceptional strength (1 TPa), lightweight | Stronger, lighter materials for aerospace & automotive |

| Advanced Sensors & Filters | Atomic thinness, sensitivity | Highly precise chemical/biological detectors, efficient membranes |

Ready to integrate graphene's revolutionary properties into your research or product development?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed for graphene research and application testing. Whether you are developing next-generation electronics, advanced energy storage solutions, or high-performance composite materials, our expertise and products can support your innovation from the lab to the market.

Contact us today using the form below to discuss how we can help you leverage the potential of graphene. #ContactForm

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials