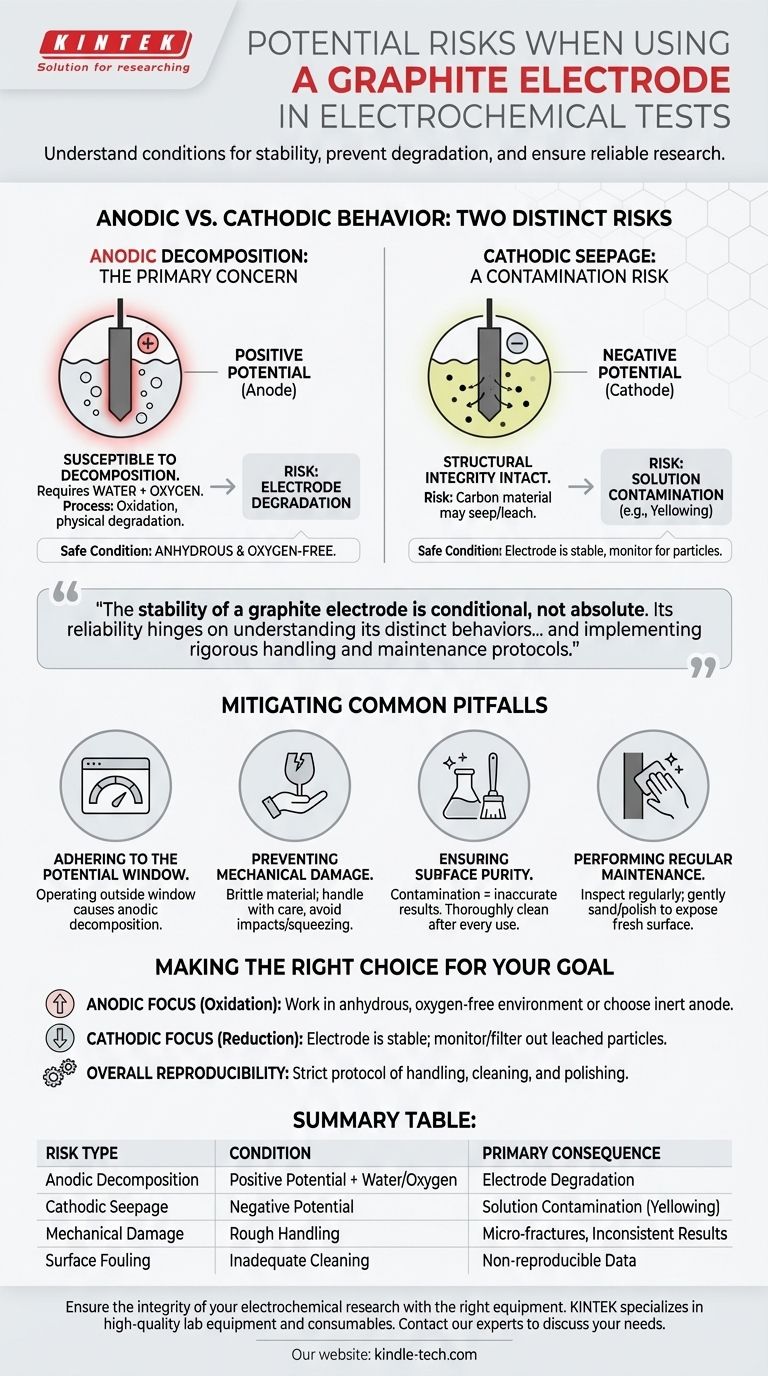

The primary risks of using a graphite electrode are electrochemical decomposition when used as an anode and material seepage when used as a cathode. These issues are directly tied to your experimental conditions, specifically the applied potential and the presence of water and oxygen, which can damage the electrode and contaminate your results.

The stability of a graphite electrode is conditional, not absolute. Its reliability hinges on understanding its distinct behaviors as an anode versus a cathode and implementing rigorous handling and maintenance protocols to prevent both physical and chemical degradation.

Anodic vs. Cathodic Behavior: Two Distinct Risks

The role you assign your graphite electrode—anode or cathode—fundamentally changes the type of risk you must manage. The direction of electron flow dictates the chemical reactions at the electrode surface.

Anodic Decomposition: The Primary Concern

When a graphite electrode operates under a positive potential (as an anode), it is susceptible to decomposition.

This process is an oxidation reaction that physically degrades the electrode material. However, it only occurs when both water and oxygen are present in the electrochemical environment.

In anhydrous (water-free) and oxygen-free conditions, this decomposition risk is effectively eliminated, making graphite a stable anode.

Cathodic Seepage: A Contamination Risk

When used under a negative potential (as a cathode), the graphite electrode itself is not electrochemically damaged. Its structural integrity remains intact.

The risk here is more subtle: fine carbon material may seep or leach from the electrode into your electrolyte solution.

A common sign of this contamination is the solution turning yellow, which can interfere with analytical measurements or subsequent experimental steps.

Mitigating Common Pitfalls

Beyond the electrochemical behavior, several practical factors can compromise your experiments. Proactive management of these issues is essential for obtaining reliable data.

Adhering to the Potential Window

Every electrode has a specified potential window within which it remains stable. Operating a graphite electrode outside this window is the direct cause of the anodic decomposition previously described. Always verify and respect these limits.

Preventing Mechanical Damage

Graphite is a brittle material. It is highly susceptible to physical damage that can alter its electrochemical properties.

Handle electrodes with care, avoiding impacts or squeezing. When sanding or polishing the surface, use only moderate force to prevent creating micro-fractures.

Ensuring Surface Purity

The electrode surface is where the reaction occurs. Any contamination will lead to inaccurate and non-reproducible results.

Thoroughly clean the electrode after every use to remove residual reactants or products.

Performing Regular Maintenance

Over time, the electrode's surface can become passive or degraded. Regularly inspect the surface condition.

If it appears dull, uneven, or fouled, gently sand or polish it to expose a fresh, electrochemically active surface.

Making the Right Choice for Your Goal

Your experimental objective determines which risks are most critical to mitigate.

- If your primary focus is on anodic processes (oxidation): You must work in an anhydrous, oxygen-free environment or choose a more inert anode material to prevent electrode decomposition.

- If your primary focus is on cathodic processes (reduction): Be aware that while the electrode is stable, you must monitor for and filter out any leached carbon particles to avoid solution contamination.

- If your primary focus is overall reproducibility: Implement a strict protocol of careful handling, meticulous cleaning, and regular surface polishing to ensure consistent performance.

Ultimately, managing these risks proactively is the key to leveraging graphite's advantages while ensuring the integrity of your electrochemical research.

Summary Table:

| Risk Type | Condition | Primary Consequence |

|---|---|---|

| Anodic Decomposition | Positive potential + Water/Oxygen | Electrode degradation |

| Cathodic Seepage | Negative potential | Solution contamination (e.g., yellowing) |

| Mechanical Damage | Rough handling | Micro-fractures, inconsistent results |

| Surface Fouling | Inadequate cleaning | Non-reproducible data |

Ensure the integrity of your electrochemical research with the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including durable electrodes and purification systems, to help you maintain precise experimental conditions and achieve reliable, reproducible results. Contact our experts today to discuss your specific laboratory needs and find the perfect solution for your research.

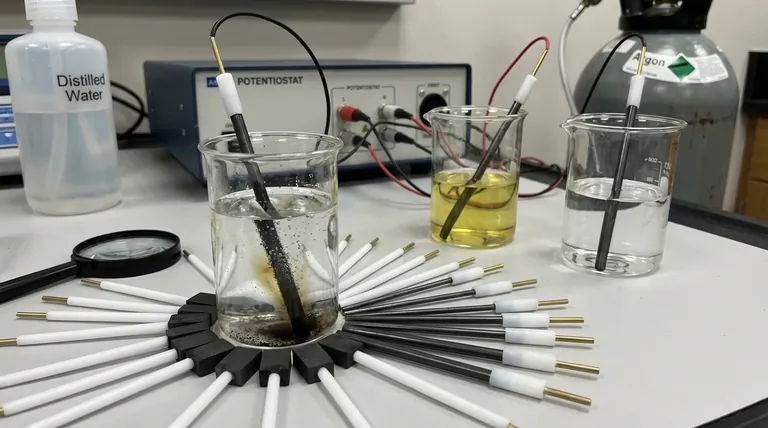

Visual Guide

Related Products

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Glassy Carbon Electrochemical Electrode

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Sample Support Body for Electrochemical Tests

People Also Ask

- What are the properties of graphite rods? Leverage High Conductivity for Extreme Applications

- What technical advantages do carbon graphite electrodes offer for electroactive biofilms? Optimize Your Bio-Research

- What are the features and common uses of a graphite rod electrode? A Guide to Durable, Simple Electrochemistry

- Why is a high-purity graphite rod selected as the EIS counter electrode? Ensure Data Integrity and Chemical Stability

- What is the primary function of high-purity graphite electrodes in AC leaching? Powering Efficient Metal Recovery