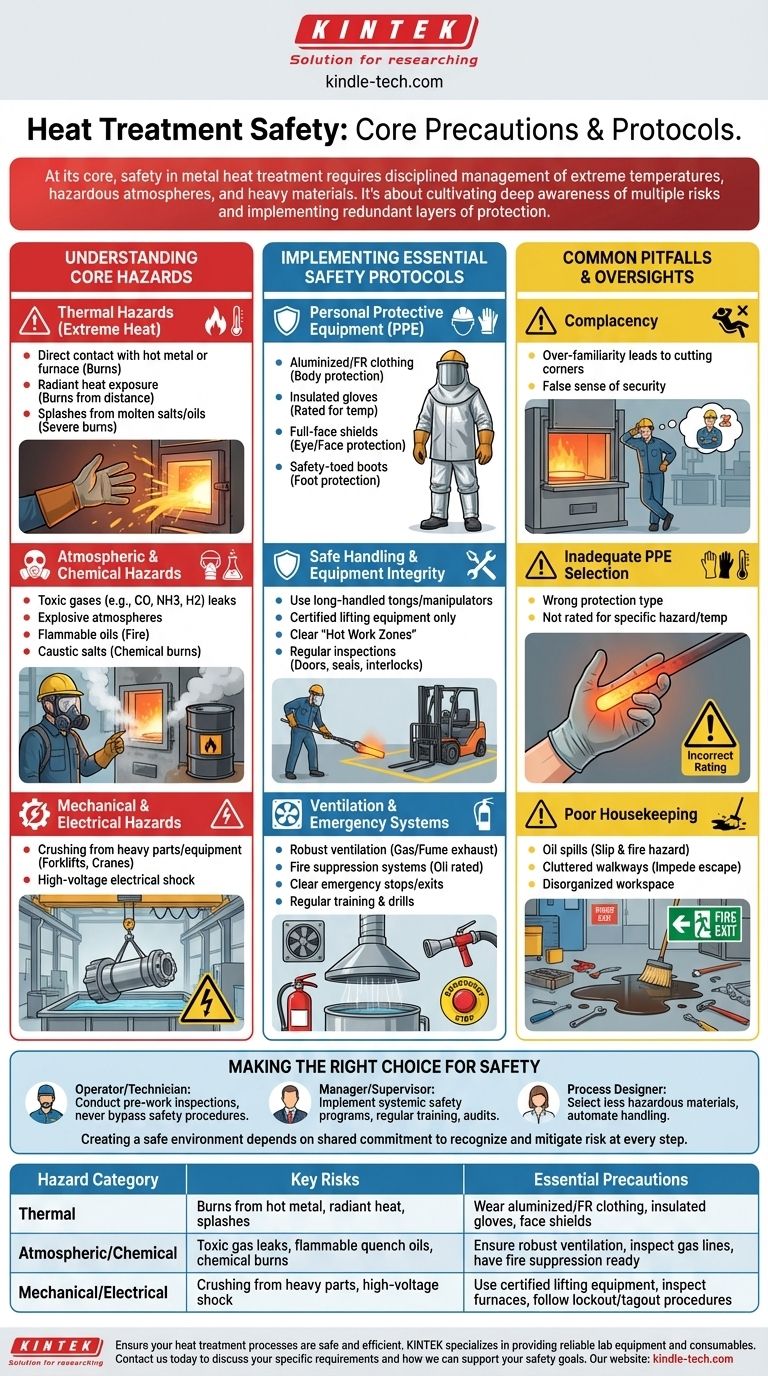

At its core, ensuring safety in metal heat treatment requires a disciplined approach to managing extreme temperatures, hazardous atmospheres, and heavy materials. Key precautions involve wearing specialized Personal Protective Equipment (PPE), maintaining furnace and handling equipment meticulously, ensuring adequate ventilation, and following strict, documented procedures for moving materials at every stage of the process.

The fundamental principle of heat treatment safety is not merely following a checklist, but cultivating a deep awareness of the multiple, overlapping risks—thermal, chemical, and mechanical—and implementing redundant layers of protection to mitigate them.

Understanding the Core Hazards

To implement effective safety measures, you must first understand the specific dangers inherent in the heat treatment process. These processes involve temperatures that can exceed 2,400°F (1315°C) and can present severe, immediate threats.

Thermal Hazards

The most obvious risk is the extreme heat. This danger manifests in several ways: direct contact with hot metal or furnace interiors, radiant heat that can cause burns from a distance, and the potential for splashes from molten salts or quenching oils.

Atmospheric and Chemical Hazards

Many heat treatment processes, like carburizing, occur in controlled atmospheres containing gases such as carbon monoxide, ammonia, or hydrogen. Leaks can create toxic environments or explosive atmospheres. Quenching baths often use oils, which are flammable, or caustic salts, which can cause severe chemical burns.

Mechanical and Electrical Hazards

Furnaces, quenching tanks, and the metal parts themselves are often heavy. The equipment used to move them, such as cranes and forklifts, presents significant crushing hazards. Furthermore, the high-power requirements of industrial furnaces introduce the risk of high-voltage electrical shock.

Implementing Essential Safety Protocols

A safe operation is built on a foundation of clear, non-negotiable protocols designed to counter the core hazards. These rules must be understood, practiced, and enforced without exception.

Personal Protective Equipment (PPE) is Non-Negotiable

Standard work clothes are inadequate. Proper PPE is your first and most critical line of defense. This includes aluminized or flame-resistant (FR) clothing, insulated gloves rated for the specific temperatures, full-face shields, and safety-toed boots. The specific PPE must match the specific task.

Safe Handling and Material Transport

Never handle hot materials without the proper tools, such as long-handled tongs or specialized manipulators. For heavy parts, use only certified and inspected lifting equipment. Work areas must have clearly marked "hot work zones," and communication between team members during transport is critical.

Furnace and Equipment Integrity

Regularly inspect furnaces, paying close attention to door seals, gas and electrical connections, and temperature controllers. Ensure all safety interlocks, which prevent doors from being opened under dangerous conditions, are functional. A preventative maintenance schedule is not optional; it is essential.

Ventilation and Emergency Systems

Your facility must have robust ventilation to safely exhaust process gases and fumes from quench tanks. Fire suppression systems, especially those rated for oil fires, must be readily available and regularly inspected. All personnel must know the location of emergency stops and fire extinguishers.

Common Pitfalls and Oversights

Accidents rarely occur in a vacuum. They are often the result of seemingly small oversights or a gradual erosion of discipline.

Complacency: The Greatest Danger

The most significant risk in any routine industrial process is complacency. Experienced operators who become overly familiar with the process may be tempted to cut corners. This false sense of security is where the majority of incidents originate.

Inadequate PPE Selection

Using the wrong type of protection can be as dangerous as using none at all. For example, a glove rated for 500°F provides no protection when handling a part at 1,500°F. Always verify that your PPE is rated for the specific hazard you face.

Poor Housekeeping

An untidy work environment creates numerous secondary risks. Oil spills on the floor are a slip and fire hazard. Cluttered walkways can impede a swift escape in an emergency. Maintaining a clean and organized workspace is a foundational safety practice.

Making the Right Choice for Your Goal

Building a culture of safety requires every person to understand their role and responsibilities.

- If you are an operator or technician: Always conduct a pre-work inspection of your PPE and workspace, and never bypass a safety procedure, no matter how routine the task feels.

- If you are a manager or supervisor: Your priority is to implement and enforce a systemic safety program, including regular training, equipment audits, and clear emergency response plans.

- If you are designing a heat treatment process: Build safety in from the start by selecting the least hazardous materials and automating handling where possible to minimize human exposure.

Ultimately, creating a safe heat treatment environment depends on the shared commitment of every individual to recognize and mitigate risk at every step.

Summary Table:

| Hazard Category | Key Risks | Essential Precautions |

|---|---|---|

| Thermal | Burns from hot metal, radiant heat, splashes | Wear aluminized/FR clothing, insulated gloves, face shields |

| Atmospheric/Chemical | Toxic gas leaks, flammable quench oils, chemical burns | Ensure robust ventilation, inspect gas lines, have fire suppression ready |

| Mechanical/Electrical | Crushing from heavy parts, high-voltage shock | Use certified lifting equipment, inspect furnaces, follow lockout/tagout procedures |

Ensure your heat treatment processes are safe and efficient. KINTEK specializes in providing reliable lab equipment and consumables for laboratory needs. Our expertise helps you mitigate risks and maintain a secure working environment. Contact us today to discuss your specific requirements and how we can support your safety goals.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of vacuum drying equipment in the processing of SiC/B4C composite powders? Prevent Agglomeration Today

- What are the heating methods in a laboratory? Choose the Right Tool for Safe & Precise Results

- What are the safety precautions during heat treatment? A Guide to Managing Extreme Heat, Gases & Hazards

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs

- What is the application of pyrolysis in waste management? Unlock Waste into Energy & Resources

- Why is a controlled drying oven used at a low temperature of 50°C for mineral products? Ensure Sample Integrity

- What is coating film thickness? The Key to Coating Performance, Durability, and Cost Control

- Why is a powerful magnetic stirrer essential during photocatalytic degradation? Ensure Accurate Catalyst Performance