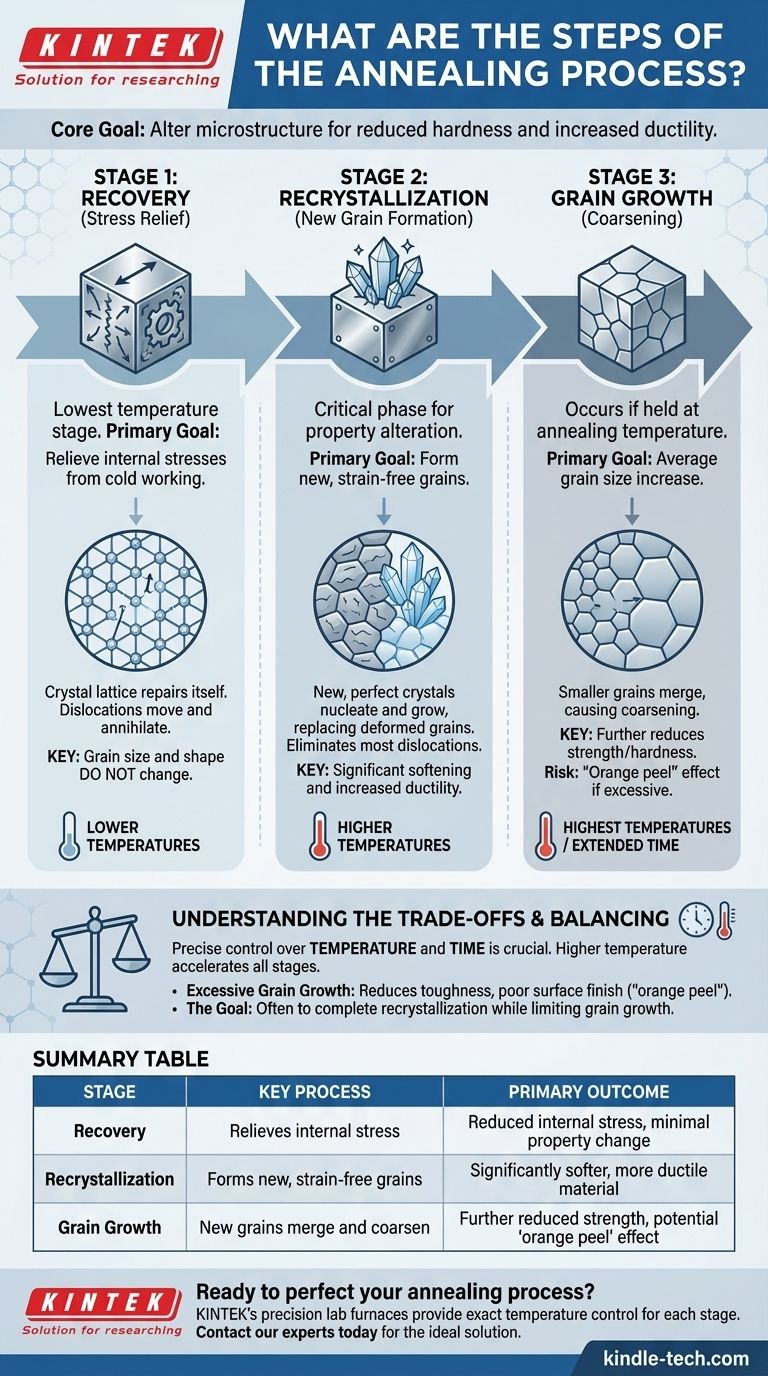

At its core, the annealing process is a heat treatment that alters a material's microstructure to achieve desired properties like reduced hardness and increased ductility. It is defined by three distinct and sequential stages that occur as the temperature is increased: Recovery, Recrystallization, and Grain Growth. Each stage systematically reverses the effects of work hardening by repairing and reconfiguring the material's internal crystal structure.

Annealing is not simply a matter of heating and cooling a metal. It is a precise, three-stage microstructural transformation that first relieves internal stress, then replaces deformed crystals with new ones, and finally allows those new crystals to grow.

The Three Stages of Microstructural Change

The entire purpose of annealing is to manipulate the internal grain structure of a material. As the material is heated, it passes through three predictable phases, each with a unique effect on its mechanical properties.

Stage 1: Recovery (Stress Relief)

This is the first and lowest-temperature stage of the process. During recovery, the primary goal is to relieve the internal stresses that have built up within the material from processes like cold working.

The metal begins to soften as the crystal lattice is given enough thermal energy to repair itself. This happens through the movement and annihilation of dislocations, which are linear defects in the crystal structure.

Crucially, the overall size and shape of the grains do not change during recovery. The material becomes less stressed internally, but its fundamental grain map remains the same.

Stage 2: Recrystallization (New Grain Formation)

As the temperature continues to rise, the material enters the recrystallization stage. This is the most critical phase for significantly altering the material's properties.

During recrystallization, new, strain-free grains begin to nucleate and grow. These new, perfect crystals form at the boundaries of the old, deformed grains and eventually consume them entirely.

This process eliminates the vast majority of dislocations and replaces the hardened, stressed structure with a new, softer, more ductile one. It is the primary mechanism for reversing the effects of work hardening.

Stage 3: Grain Growth (Coarsening)

If the material is held at the annealing temperature after recrystallization is complete, grain growth begins. There are no new grains forming at this point.

Instead, the smaller of the new, strain-free grains begin to merge into their larger neighbors. This causes the average grain size to increase, a process also known as coarsening. This further reduces the material's strength and hardness.

Understanding the Trade-offs

While annealing is a powerful tool, it is not without complexity. The transition between stages, particularly from recrystallization to grain growth, must be carefully managed to avoid undesirable outcomes.

The Problem with Excessive Grain Growth

Achieving a large grain size can be a specific goal, but uncontrolled or excessive grain growth is often detrimental.

Extremely large grains can reduce a material's toughness and lead to a poor surface finish, known as the "orange peel" effect, if the part is subsequently formed or bent. The goal is often to complete recrystallization while limiting the extent of grain growth.

Balancing Temperature and Time

The success of an annealing process depends on precise control over both temperature and time. A higher temperature can cause the three stages to proceed much more quickly.

The key is to hold the material at the right temperature for just long enough to achieve complete recrystallization without allowing significant grain growth to occur, unless that is the specific intent.

Making the Right Choice for Your Goal

The annealing parameters you choose should directly reflect the final properties you need to achieve in your material.

- If your primary focus is stress relief with minimal change in strength: Your process should be designed to conclude within the Recovery stage, using lower temperatures and shorter times.

- If your primary focus is maximizing ductility and softness: You must ensure the material fully completes the Recrystallization stage, creating an entirely new grain structure.

- If your primary focus is balancing strength and formability: You need to complete recrystallization while carefully controlling or preventing the Grain Growth stage to maintain a fine-grained structure.

By understanding these three distinct stages, you can move from simply heating a material to precisely engineering its final mechanical properties.

Summary Table:

| Stage | Key Process | Primary Outcome |

|---|---|---|

| Recovery | Relieves internal stress | Reduced internal stress, minimal property change |

| Recrystallization | Forms new, strain-free grains | Significantly softer, more ductile material |

| Grain Growth | New grains merge and coarsen | Further reduced strength, potential for 'orange peel' effect |

Ready to perfect your annealing process?

KINTEK's precision lab furnaces provide the exact temperature control and uniformity required to master each stage of annealing—from stress relief to controlled grain growth. Whether you're working with metals or advanced alloys, our equipment ensures you achieve the precise material properties you need.

Contact our experts today to find the ideal annealing solution for your laboratory's specific requirements.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is meant by annealing process? Transform Brittle Metals into Workable Materials

- Why must thermal cycling tests for bimetallic composite pipe cross-sections be performed in a vacuum heating furnace?

- What are the advantages of insulation in a furnace? Maximize Efficiency, Performance, and Lifespan

- What critical process conditions does a vacuum sintering furnace provide for titanium? Expert Diffusion Bonding Guide

- What critical conditions must a furnace provide for 1.25Cr-0.5Mo austenitization? Achieve Precise Thermal Control

- How do you maintain vacuum pressure? Master the balance between gas removal and gas load for stable performance.

- What is the vacuum level of a vacuum furnace? Match the Right Vacuum to Your Process

- What role do condensation devices play in the recovery of magnesium during vacuum distillation? Optimize Metal Yield