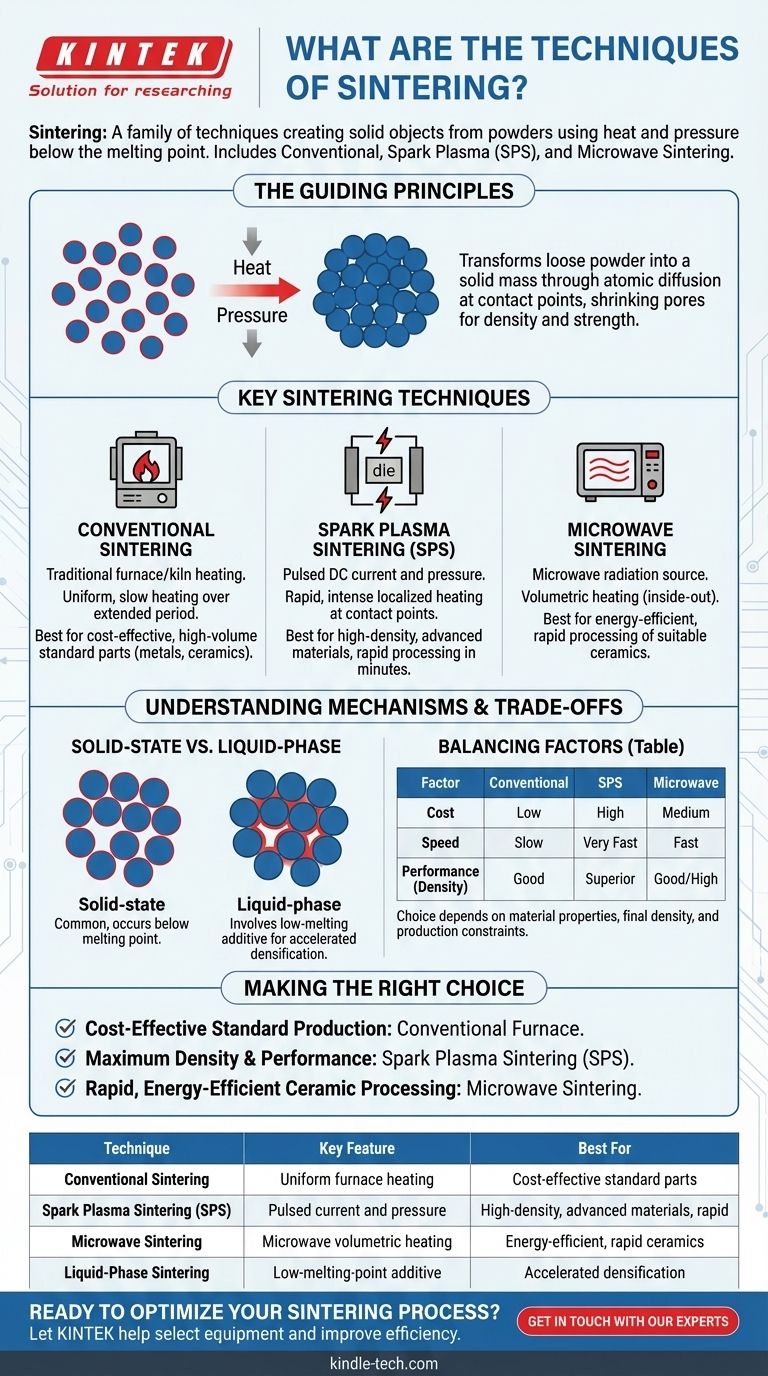

At its core, sintering is not a single process but a family of techniques used to create solid objects from powders using heat and sometimes pressure. The primary methods include Conventional Sintering in a furnace, advanced electrical methods like Spark Plasma Sintering (SPS), and energy-efficient approaches like Microwave Sintering, each chosen based on the material and desired outcome.

The specific sintering technique chosen is a strategic decision dictated by the material's properties, the required final density and strength of the part, and constraints like cost and production speed. There is no single "best" method; there is only the right method for the application.

The Guiding Principles of Sintering

Before comparing techniques, it's essential to understand the fundamental goal. Sintering transforms a collection of loose particles—whether metal, ceramic, or a composite—into a coherent, solid mass.

What Happens During Sintering?

The process works by heating the material to a high temperature, but critically, below its melting point. At this temperature, atoms at the contact points between particles diffuse, causing the particles to fuse together.

This atomic movement reduces the surface area of the individual particles and shrinks the pores between them, leading to a denser, stronger final component.

Key Sintering Techniques Explained

The various techniques are primarily distinguished by how they deliver heat and whether they apply external pressure to aid the process.

Conventional Sintering

This is the most traditional and widely used method. The compacted powder part, often called a "green part," is placed in a furnace or kiln.

Heat is applied slowly and uniformly, allowing the part to sinter over an extended period. This method is highly effective for a wide range of materials, from porcelain to basic metal parts.

Spark Plasma Sintering (SPS)

SPS is a modern, advanced technique that combines heat and pressure. A pulsed DC electrical current is passed directly through the powder and the graphite die containing it.

This generates rapid, intense heat localized at the particle contact points, while simultaneous mechanical pressure is applied. This combination dramatically accelerates the densification process, often taking only minutes instead of hours.

Microwave Sintering

This method uses microwave radiation as the heat source. Unlike a conventional furnace that heats from the outside-in, microwaves can heat the material volumetrically (from the inside-out).

This can lead to more uniform heating, faster processing times, and potential energy savings, particularly for certain types of ceramic materials.

Solid-State vs. Liquid-Phase Sintering

These terms describe the mechanism, not the equipment. Solid-state sintering, the most common form, occurs entirely without any melting.

Liquid-phase sintering involves adding a secondary material with a lower melting point to the powder mix. During heating, this secondary material melts, creating a liquid that helps pull the primary particles together through capillary action, accelerating densification.

Understanding the Trade-offs

Choosing a sintering technique involves balancing speed, cost, performance, and material compatibility. No single method is superior in all aspects.

Cost vs. Performance

Conventional sintering is generally the most cost-effective solution for high-volume production due to simpler equipment. However, it is slow and may not achieve the highest possible densities.

Spark Plasma Sintering (SPS) offers superior performance, achieving near-full density in a fraction of the time. This performance comes at the cost of highly specialized, expensive equipment and is typically reserved for advanced materials and research.

Speed vs. Complexity

Microwave and SPS techniques offer significant speed advantages over conventional methods. However, this speed requires more complex process control to manage rapid heating and prevent thermal stresses or non-uniformity within the part.

Material Compatibility

Certain materials respond better to specific techniques. For example, some advanced non-oxide ceramics require the precisely controlled atmosphere and temperature possible in specialized furnaces, while the rapid heating of SPS is ideal for processing novel alloys and biomaterials that might degrade during long conventional cycles.

Making the Right Choice for Your Goal

Your final decision should be guided by the end-use application of the part you are creating.

- If your primary focus is cost-effective production of standard metal or ceramic parts: Conventional furnace sintering is the established and reliable choice.

- If your primary focus is achieving maximum density and superior mechanical properties in advanced materials: Spark Plasma Sintering (SPS) is the leading technology for high-performance applications.

- If your primary focus is rapid, energy-efficient processing of suitable ceramic materials: Microwave sintering presents a compelling modern alternative to conventional methods.

Ultimately, effective sintering is about precisely matching the processing technique to the unique characteristics of the material and the performance demands of the final component.

Summary Table:

| Technique | Key Feature | Best For |

|---|---|---|

| Conventional Sintering | Uses a furnace for uniform heating | Cost-effective production of standard parts |

| Spark Plasma Sintering (SPS) | Applies pulsed current and pressure | High-density, advanced materials, rapid processing |

| Microwave Sintering | Uses microwave radiation for volumetric heating | Energy-efficient, rapid processing of ceramics |

| Liquid-Phase Sintering | Uses a low-melting-point additive | Accelerated densification of certain materials |

Ready to Optimize Your Sintering Process?

Choosing the right sintering technique is critical for achieving the desired density, strength, and performance in your components. The experts at KINTEK are here to help.

We specialize in providing the ideal lab equipment and consumables for your specific sintering needs, whether you're working with conventional furnaces or advanced systems like SPS.

Let us help you:

- Select the right equipment for your material and application goals.

- Improve your process efficiency and final product quality.

- Access expert technical support to get the most out of your sintering operations.

Contact us today for a consultation and discover how KINTEK's solutions can advance your materials research and production.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- What is the sintering time? A Critical Process Variable for Material Density and Strength

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?