At its core, sintering is the process of fusing ceramic particles into a solid, dense mass using heat, often supplemented by pressure, without melting the material. The primary techniques are categorized by the physical mechanisms they employ: solid-state sintering, which relies purely on heat-driven diffusion; liquid-phase sintering, which uses a small amount of liquid to accelerate the process; and pressure-assisted sintering, which applies external force to enhance densification and achieve superior properties.

The central challenge in sintering ceramics is achieving maximum density and strength while preventing unwanted grain growth. The choice of technique is therefore a strategic trade-off between the final desired properties, processing time, and equipment cost.

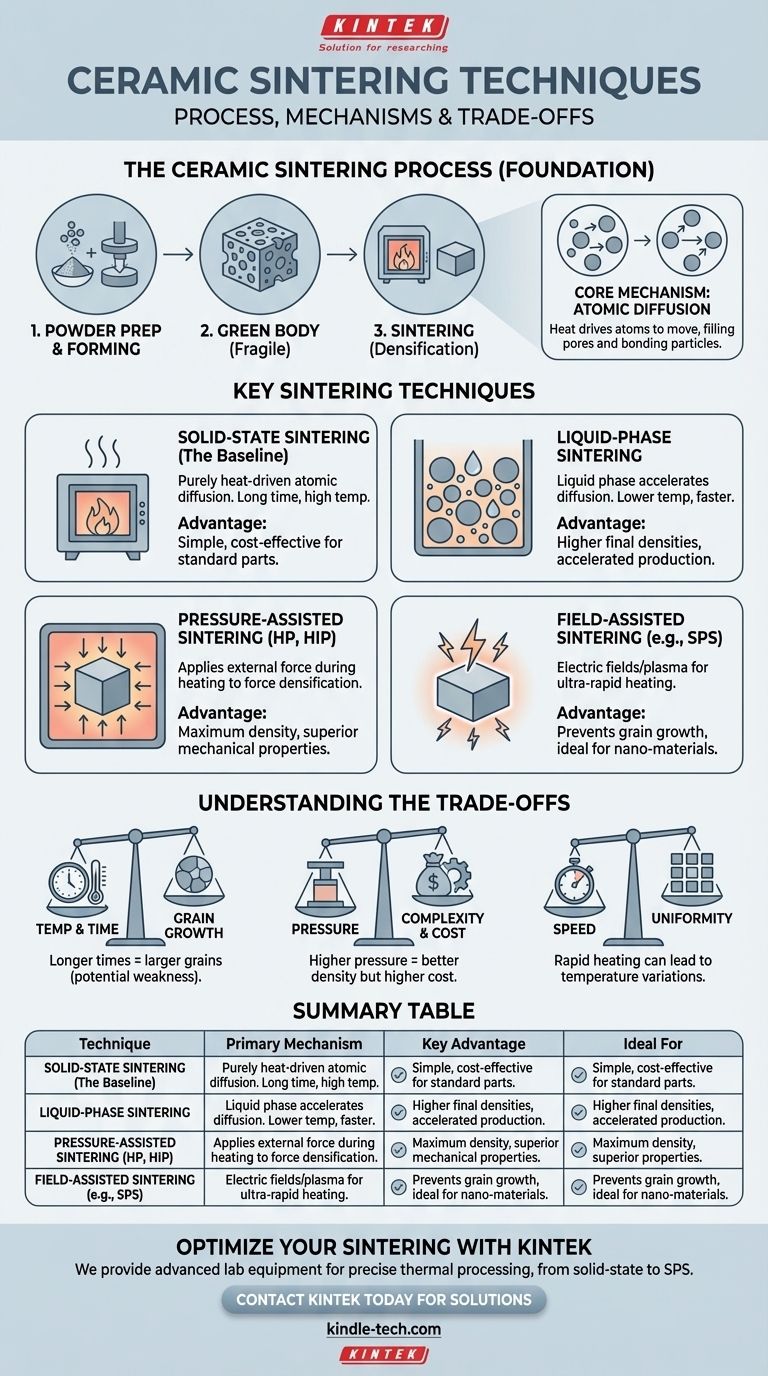

The Foundation: The Ceramic Sintering Process

Before examining specific techniques, it's crucial to understand where sintering fits within the overall manufacturing workflow. It is not a standalone step but the critical densification phase that transforms a fragile powder compact into a robust component.

From Powder to Part: The General Workflow

The journey begins by preparing a homogenous mixture of ceramic powder, a binder, and other agents into a slurry. This slurry is often spray-dried to create uniform granules ready for pressing.

This powder is then compacted in a mold or die to form a "green body." This part is fragile, held together only by the binder, but has the desired shape.

The green body is first heated at a low temperature to carefully burn off the binder. Finally, it undergoes high-temperature sintering, where the ceramic particles fuse, the part shrinks, and it gains its final density and strength.

The Core Mechanism: Atomic Diffusion

Sintering works by creating conditions (high heat) where atoms can move, or diffuse, across the boundaries of adjacent particles.

This atomic movement fills the voids (pores) between particles, causing them to bond together and the overall component to shrink and become denser. This happens entirely in the solid state, well below the material's melting point.

Key Sintering Techniques and Their Mechanisms

While the goal of densification is universal, the methods to achieve it vary significantly. These techniques are chosen based on the material type, cost constraints, and required final performance.

Solid-State Sintering (The Baseline)

This is the most fundamental form of sintering, relying solely on thermal energy to drive atomic diffusion. It is often called "conventional sintering."

The green body is simply placed in a high-temperature furnace for an extended period, allowing particles to slowly fuse and pores to close. While simple and widely used, it can require very high temperatures and long durations, which can lead to excessive grain growth and limit the final strength.

Liquid-Phase Sintering (Accelerating Densification)

This technique introduces a small amount of a liquid phase during heating. This liquid can be an intentional additive or result from impurities that have a lower melting point than the main ceramic powder.

The liquid wets the solid particles and acts as a high-speed transport path for atoms, dramatically accelerating diffusion and rearrangement. This allows for sintering at lower temperatures and shorter times compared to solid-state sintering, often resulting in higher final densities.

Pressure-Assisted Sintering (Forcing Densification)

For high-performance applications where maximum density is non-negotiable, external pressure is applied during the heating cycle.

Hot Pressing (HP) involves simultaneously heating and applying uniaxial (one-direction) pressure to the powder in a die. This force physically aids in particle rearrangement and pore closure, producing highly dense parts.

Hot Isostatic Pressing (HIP) is a more advanced method where the part is heated in a high-pressure inert gas environment. The pressure is isostatic (equal from all directions), allowing for the densification of complex shapes and the healing of internal defects.

Field-Assisted Sintering (Advanced & Rapid)

These cutting-edge techniques use electric fields or microwaves to deliver heat in a fundamentally different way, solving many of the problems of conventional methods.

A prominent example is Spark Plasma Sintering (SPS). In SPS, a pulsed DC current is passed directly through the powder and tooling. This creates extremely rapid heating rates and plasma between particles, allowing for full densification in minutes instead of hours. The speed is critical for preventing grain growth, making it ideal for creating nano-structured ceramics.

Understanding the Trade-offs: Method vs. Microstructure

The choice of a sintering technique is never made in isolation. It is a calculated decision based on a critical balance of competing factors.

Temperature and Time vs. Grain Growth

This is the classic dilemma of conventional sintering. The heat and time required to eliminate porosity also provide the energy for grains to grow larger. While a dense part is strong, excessively large grains can become a source of weakness and fracture.

Pressure vs. Complexity and Cost

Pressure-assisted methods like HP and HIP are exceptionally effective at producing dense, fine-grained ceramics at lower temperatures. However, the equipment is significantly more expensive and complex, and throughput is often lower, making it unsuitable for low-cost, high-volume production.

Speed vs. Uniformity

Advanced, rapid techniques like SPS are revolutionary for developing new materials and preserving nano-scale features. The trade-off can be challenges in achieving perfectly uniform temperature distribution across large or complex-shaped parts, which can lead to variations in density and stress.

Choosing the Right Sintering Strategy

Your choice must be guided by the end goal for the component. There is no single "best" technique, only the most appropriate one for a specific application.

- If your primary focus is cost-effective production of standard parts: Solid-state or liquid-phase sintering provides a reliable and economical balance of properties for items like tiles or insulators.

- If your primary focus is maximum density and mechanical performance: Pressure-assisted methods like Hot Isostatic Pressing (HIP) are the industry standard for critical components like bearings or armor.

- If your primary focus is preserving nanostructures or developing advanced materials: Field-assisted techniques like Spark Plasma Sintering (SPS) are essential to achieve densification without sacrificing fine grain structure.

Ultimately, selecting the right sintering technique is about precisely controlling the material's microstructure to achieve the desired performance in the final component.

Summary Table:

| Technique | Primary Mechanism | Key Advantage | Ideal For |

|---|---|---|---|

| Solid-State Sintering | Heat-driven atomic diffusion | Simple, cost-effective | Standard parts, tiles, insulators |

| Liquid-Phase Sintering | Liquid-phase accelerated diffusion | Lower temperatures, faster densification | Accelerated production with high density |

| Pressure-Assisted Sintering | Heat + External pressure | Maximum density, superior properties | Critical components like bearings, armor |

| Field-Assisted Sintering (e.g., SPS) | Electric field/plasma heating | Ultra-fast, prevents grain growth | Nano-structured/advanced materials |

Ready to Optimize Your Ceramic Sintering Process?

Choosing the right sintering technique is critical for achieving the density, strength, and microstructure your application demands. The experts at KINTEK specialize in providing the advanced lab equipment and consumables necessary for precise thermal processing.

We help laboratories and manufacturers select the right furnaces and tooling for techniques ranging from conventional solid-state sintering to advanced Spark Plasma Sintering (SPS). Let us help you achieve superior results and accelerate your R&D or production.

Contact KINTEK today to discuss your specific ceramic sintering needs and discover the optimal solution for your lab.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why Use a Programmed Muffle Furnace for Plastic-Derived Carbon? Master Precision for Superior Yield & Structure

- How do high-temperature box resistance furnaces regulate the microstructure of T91 and HT9 steels? Precise Thermal Control

- What is the function of a high-temperature muffle furnace in LLTO nanofiber preparation? Key Roles in Calcination

- Why is the forced air drying oven essential for CoxAl3FeyOm catalyst preparation? Key Pre-treatment Insights

- Why is a high-temperature muffle furnace required for the calcination treatment of tin-niobium mixed oxides?

- How can I reduce my sintering? Switch to Advanced Methods for Faster, Lower-Temp Processing

- How does a multi-step heat treatment program benefit Li-Zr-P-O electrolyte synthesis? Optimize Your Solid Electrolytes

- What is the temperature of a sintering oven? Master the Key to Perfect Material Properties