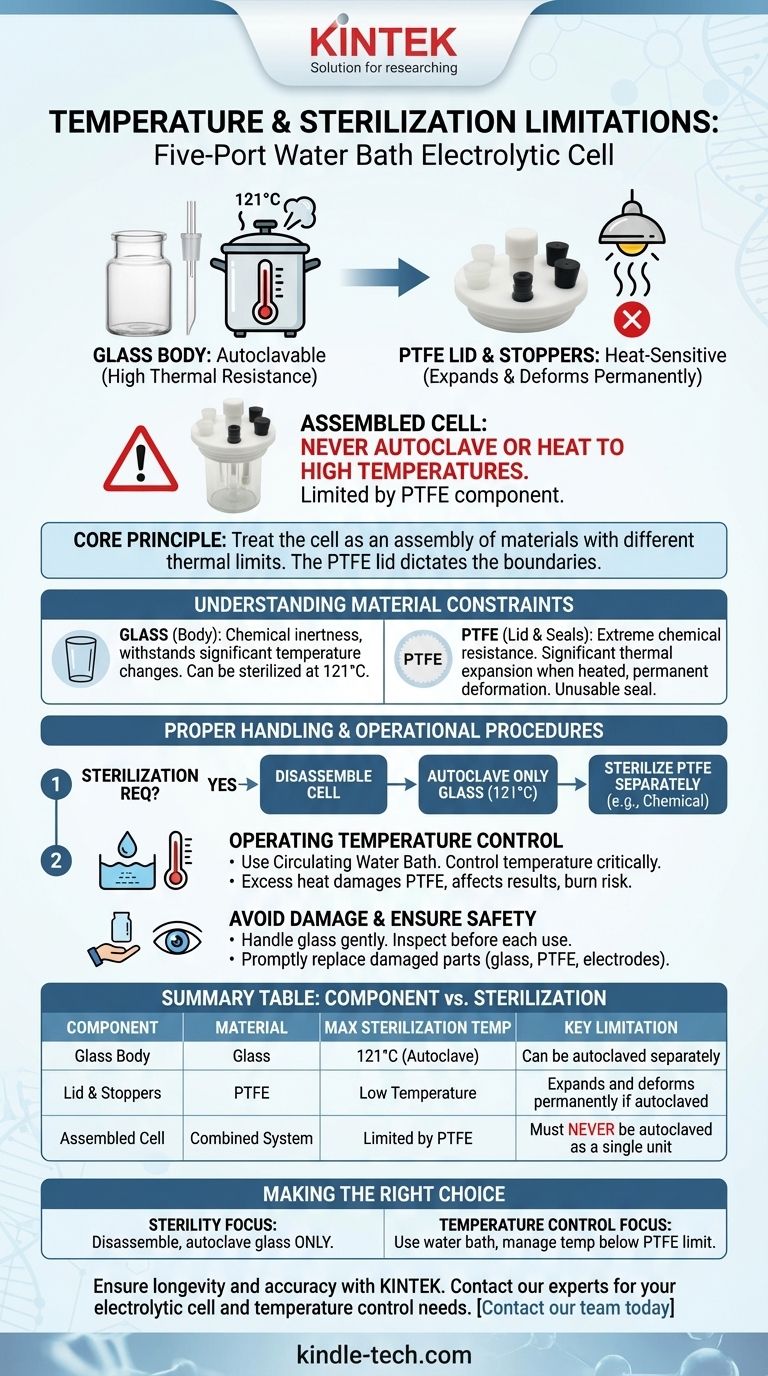

The fundamental limitation of the five-port water bath electrolytic cell is the difference in thermal properties between its components. The glass body can be sterilized by autoclaving at 121°C, but the Polytetrafluoroethylene (PTFE) lid will expand and deform permanently if heated. Therefore, the entire assembled cell must never be autoclaved or heated to high temperatures.

The core principle is to treat the cell not as a single unit, but as an assembly of materials with different thermal limits. All sterilization and temperature control procedures must respect the fact that the PTFE lid is the most heat-sensitive component, dictating the operational boundaries for the entire system.

Understanding the Material Constraints

To use the cell effectively and safely, you must understand why its components react differently to heat. The design intentionally uses different materials for their unique properties, but this creates specific handling requirements.

The Glass Body: High Thermal Resistance

The cell body is made of glass, a material chosen for its chemical inertness and ability to withstand significant temperature changes.

This allows the glass portion alone to be sterilized using a standard autoclave process, which typically involves steam at 121°C under high pressure.

The PTFE Lid and Stoppers: The Limiting Factor

The lid, stoppers, and other seals are made from Polytetrafluoroethylene (PTFE), a fluoropolymer known for its extreme chemical resistance.

However, PTFE undergoes significant thermal expansion when heated. Even if it doesn't melt, heating it to autoclave temperatures will cause it to expand and permanently lose its original shape, compromising the seal and rendering the lid unusable.

The Assembled Cell: A System of Constraints

Because the PTFE lid cannot handle high temperatures, the entire assembly is limited by this constraint.

Attempting to heat or autoclave the fully assembled cell will inevitably damage the PTFE components, leading to experimental failure and the need for replacement parts.

Proper Handling and Operational Procedures

Adhering to correct procedures for sterilization and temperature control is not just a recommendation; it is essential for the longevity of the equipment and the validity of your experimental results.

How to Sterilize Components Separately

If sterilization is required, you must first disassemble the cell.

Only the glass body and any other glass components (like a Luggin capillary) can be placed in an autoclave. All PTFE parts must be sterilized by other means suitable for the material, such as chemical sterilization (not detailed in the provided references).

Operating Temperature Considerations

The cell is designed for temperature control using a circulating water bath.

While a specific maximum operating temperature is not given, it is critical to control the water bath temperature. Excessively high temperatures can not only damage the PTFE components through expansion but also adversely affect experimental results and pose a significant burn risk.

Avoiding Damage and Ensuring Safety

Always handle the glass cell gently to prevent breakage. Before each use, perform a visual inspection.

Regularly check all components, including the glass body, PTFE seals, and electrodes. Promptly replace any part that shows signs of damage, wear, or deformation to ensure a proper seal and accurate measurements.

Making the Right Choice for Your Goal

Your experimental goal dictates how you should approach these limitations.

- If your primary focus is sterility: Always disassemble the cell completely and autoclave only the glass components at 121°C.

- If your primary focus is a temperature-controlled reaction: Use a water bath, but carefully manage the temperature to a level that is effective for your experiment without causing the PTFE lid to expand or creating a safety hazard.

Understanding these material-based limitations is the key to ensuring both accurate results and the long-term integrity of your equipment.

Summary Table:

| Component | Material | Maximum Sterilization Temperature | Key Limitation |

|---|---|---|---|

| Glass Body | Glass | 121°C (Autoclave) | Can be autoclaved separately |

| Lid & Stoppers | PTFE (Polytetrafluoroethylene) | Low Temperature | Expands and deforms permanently if autoclaved |

| Assembled Cell | Combined System | Limited by PTFE | Must NEVER be autoclaved as a single unit |

Ensure the longevity and accuracy of your experiments with the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells and components designed for precise temperature control and chemical resistance. Our experts can help you select the perfect setup for your specific sterilization and temperature requirements. Contact our team today to discuss your laboratory needs and enhance your research efficiency!

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How does a three-electrode electrolytic cell function during PEC testing? Optimize MoS2 Photoanode Analysis

- What maintenance procedures are recommended for a side-window optical electrolytic cell? Ensure Data Accuracy & Extend Cell Lifespan

- How should the electrolytic cell be stored? Ensure Longevity and Data Accuracy

- What is the importance of electrolytic polishing and electrolytic cells in FeCrAl sample prep? Reveal true structures.

- What is the function of Alumina Sheaths in a molten salt electrolytic cell assembly? Essential High-Heat Protection

- What are the advantages of using a double chamber glass electrolytic cell for evaluating MFC anode performance?

- What role does a high-precision electrochemical workstation play in the leaching process of Sm2(Co,Fe,Cu,Zr)17 magnets?

- What materials are used for the caps of the sealed and non-sealed electrolysis cells? PTFE vs. POM Explained