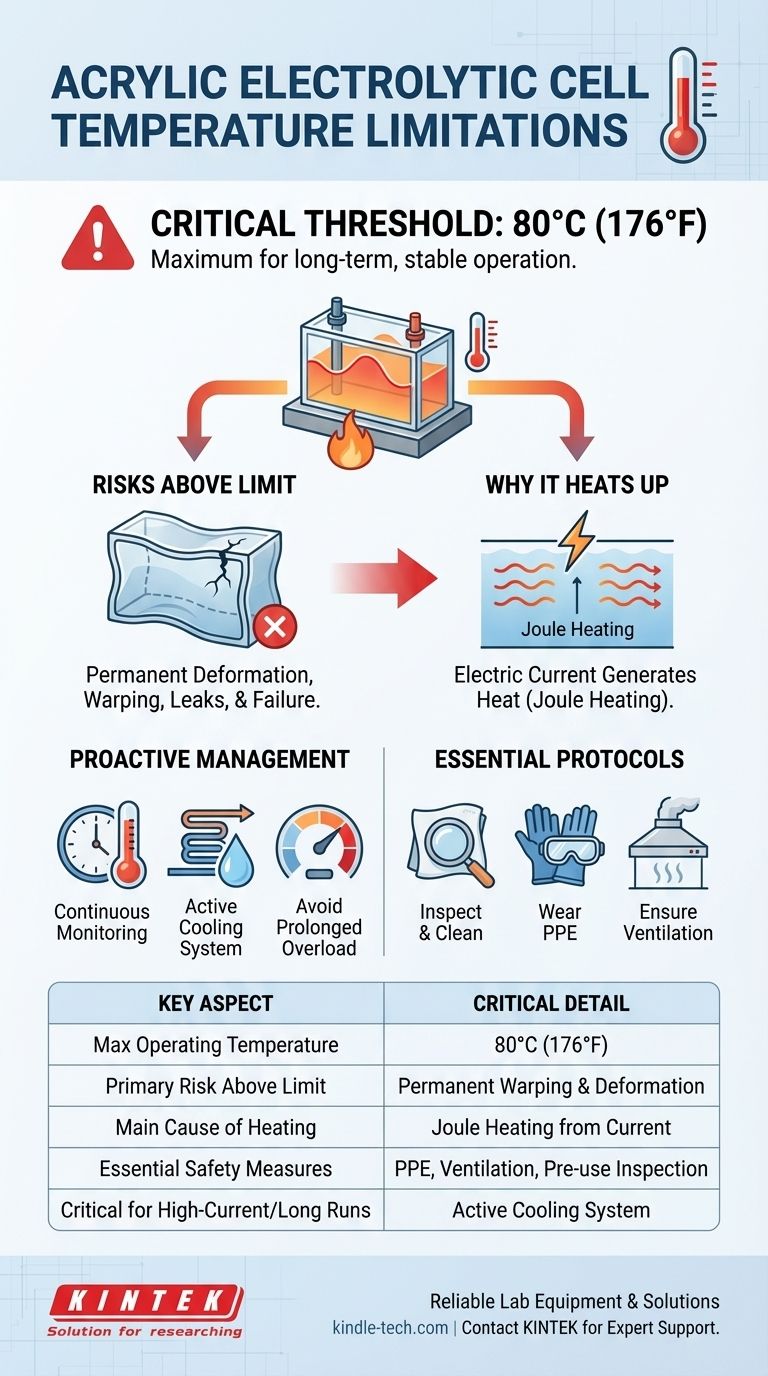

To put it directly, the recommended long-term operating temperature for an acrylic electrolytic cell is at or below 80°C (176°F). If the electrolyte temperature exceeds this limit during your process, you must actively cool the cell to prevent the acrylic material from permanently deforming.

The core issue is that while acrylic is a versatile material for electrolytic cells, its moderate heat resistance is a critical operational boundary. Exceeding 80°C doesn't just risk a failed experiment; it risks destroying the cell itself.

Understanding the Thermal Limits of Acrylic

The entire structure and integrity of your cell depend on keeping the material within its specified thermal range. Ignoring this can lead to immediate and irreversible failure.

The 80°C Threshold

The manufacturer's guideline of 80°C is the maximum for long-term, stable operation. While an ideal operating temperature is closer to room temperature, 80°C serves as the absolute ceiling you should design your process around.

The Primary Risk: Deformation

When acrylic gets too hot, it softens. This will cause the cell to warp, deform, or lose its shape. This damage compromises seals, alters electrode spacing, and can easily lead to leaks, rendering the cell useless.

Why Temperature Rises During Electrolysis

The flow of electric current through the electrolyte naturally generates heat, a phenomenon known as Joule heating. High currents or prolonged operational periods will inevitably raise the temperature of the system.

Proactive Temperature Management

Effective temperature control is not a reactive measure but a fundamental part of a well-designed experimental protocol.

Continuous Monitoring is Essential

Your experimental records must include temperature readings taken at regular intervals. This data provides the only reliable way to know if you are approaching the cell's thermal limit.

Implementing a Cooling System

If your process generates significant heat, a cooling device is mandatory. This can range from a simple cooling water bath that the cell sits in, to more integrated cooling coils running a coolant through the electrolyte.

Avoid Prolonged Overload

Running the cell at currents or voltages significantly above its intended specifications is a primary cause of rapid overheating. Adhering to the recommended operational parameters is crucial for thermal stability.

Essential Operating and Safety Protocols

Beyond temperature, proper handling is critical for ensuring both safety and the longevity of your equipment. These steps should be considered standard procedure.

Pre-Experiment Inspection and Cleaning

Before every use, visually inspect the cell body for any cracks, damage, or potential leaks. Clean it thoroughly with a suitable solvent to remove grease, then rinse with distilled water and allow it to air dry completely.

Proper Filling and Electrolyte Handling

Slowly pour the electrolyte into the cell, ensuring you do not exceed 80% of its total volume. This simple step prevents splashing and provides a safety margin.

Personal Protective Equipment (PPE)

Always wear acid and alkali-resistant gloves and safety goggles. Electrolytes are often corrosive, and direct contact can be hazardous.

Ventilation is Non-Negotiable

Acrylic cells are typically non-sealed. Since electrolysis can produce harmful gases like chlorine, you must operate the cell in a well-ventilated area or under a fume hood to prevent the buildup of hazardous fumes.

Making the Right Choice for Your Process

Your approach to thermal management should directly reflect the intensity of your work.

- If your primary focus is on low-current or short-duration experiments: Regular temperature monitoring may be sufficient, but be prepared to intervene if temperatures rise unexpectedly.

- If you are running high-current or long-duration processes: An active cooling system is not optional; it must be an integrated part of your setup from the very beginning.

- If your priority is safety and repeatability: The complete checklist of inspection, cleaning, PPE, and proper ventilation is the only way to ensure reliable and safe outcomes.

By respecting its thermal limitations and adhering to rigorous operating protocols, your acrylic electrolytic cell will remain a dependable and safe tool.

Summary Table:

| Key Aspect | Critical Detail |

|---|---|

| Max Operating Temperature | 80°C (176°F) for long-term use |

| Primary Risk Above Limit | Permanent warping and deformation of the acrylic cell body |

| Main Cause of Heating | Joule heating from electric current in the electrolyte |

| Essential Safety Measures | PPE (gloves, goggles), fume hood ventilation, pre-use inspection |

| Critical for High-Current/Long Runs | Active cooling system (e.g., water bath, cooling coils) |

Ensure Your Experiments Run Safely and Efficiently

Managing thermal limits is critical for the success and safety of your electrolysis work. At KINTEK, we specialize in providing reliable lab equipment and consumables, including solutions for temperature control and electrochemical processes.

Why choose KINTEK for your laboratory needs?

- Expert Support: Get guidance on selecting the right equipment and setting up effective cooling systems for your specific application.

- Quality Assurance: Trust in durable, precision-engineered products designed for repeatable results.

- Comprehensive Solutions: From basic cells to advanced integrated systems, we have the tools to support your research.

Don't risk your experiments or equipment. Let our experts help you build a safe and effective setup.

Contact KINTEK today for a consultation and ensure your lab operates at peak performance and safety.

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Optical Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What role does an electrolytic cell system play in metal hydrogen pre-charging? Speed Up Material Testing with KINTEK

- What is the role of a glass reactor in alkaline water electrolysis? Ensure Safety and Visual Precision

- What roles do the PTL and GDL play in electrolyzer components? Essential Insights for Mass Transport and Conductivity

- What are the advantages of using an undivided electrolytic cell for Acid Red-20? Boost Efficiency and Speed

- Why is the implementation of a zero-gap configuration significant in Copper-Chlorine cycle electrolyzers?

- How does high-temperature operation in SOC contribute to efficiency? Unlock Thermal Synergy for Hydrogen Production

- How does a three-electrode electrolytic cell system control MnO2 nanosheet loading? Achieve Micro-Level Precision

- What are the guidelines for sterilizing the electrolytic cell? Ensure Sterile, Damage-Free Lab Results