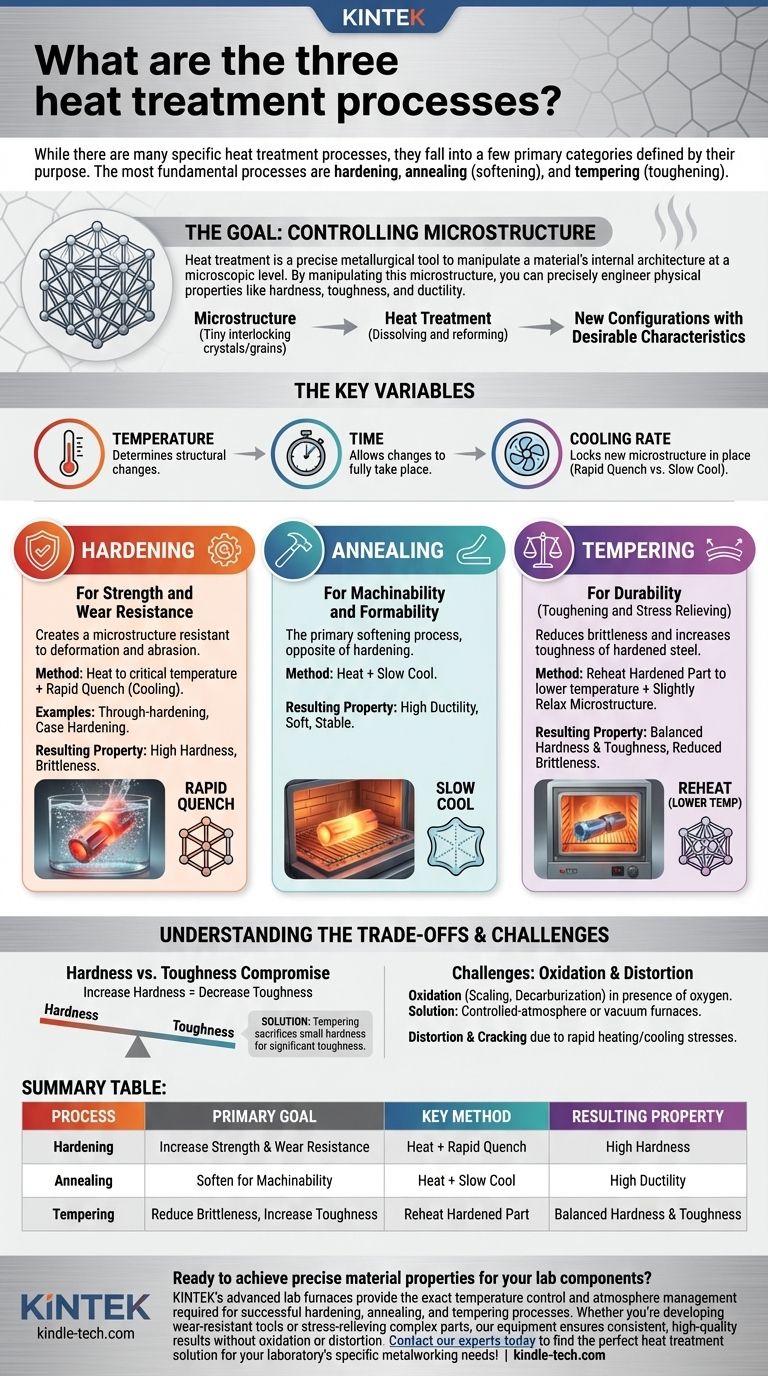

While there are many specific heat treatment processes, they are not a random collection of techniques. Instead, they fall into a few primary categories defined by their purpose: hardening the metal, softening the metal, or modifying its internal properties for toughness and stability. The most fundamental processes are hardening, annealing (softening), and tempering (toughening).

Heat treatment is the controlled application of heat to alter a metal's internal crystal structure, known as its microstructure. By manipulating this structure, you can precisely engineer its physical properties—like hardness, toughness, and ductility—to fit a specific application.

The Goal of Heat Treatment: Controlling Microstructure

Heat treatment is not simply about making metal hot. It is a precise metallurgical tool used to manipulate a material's internal architecture at a microscopic level.

What is Microstructure?

Think of a metal's internal structure as being made of tiny, interlocking crystals or grains. The size, shape, and arrangement of these grains—the microstructure—determine the metal's overall properties.

Heat treatment works by dissolving and reforming these crystalline structures into new configurations that possess more desirable characteristics.

The Key Variables: Temperature, Time, and Cooling Rate

Every heat treatment process is a function of three variables:

- Temperature: How hot the material gets determines which structural changes are possible.

- Time: How long it is held at that temperature allows those changes to fully take place throughout the material.

- Cooling Rate: How quickly it is cooled locks the new microstructure in place. A rapid quench freezes a hard structure, while a slow cool allows a soft one to form.

The Primary Categories of Heat Treatment

Instead of an arbitrary list of three processes, it's more accurate to think in terms of three primary goals. Each goal is achieved through a family of related processes.

Hardening: For Strength and Wear Resistance

Hardening processes create a microstructure that is highly resistant to deformation and abrasion. This is achieved by heating the metal to a critical temperature and then cooling it very rapidly (quenching).

Specific examples include through-hardening, which hardens the entire part, and case hardening (or surface hardening), which creates a hard, wear-resistant outer shell while leaving a softer, tougher core.

Softening: For Machinability and Formability

Annealing is the primary softening process. It is essentially the opposite of hardening. The metal is heated and then cooled very slowly.

This slow cooling allows the microstructure to form in its softest, most stable, and lowest-stress state. Annealed metal is more ductile, making it easier to machine, bend, or stamp without fracturing.

Toughening and Stress Relieving: For Durability

Hardened steel is often extremely brittle. Tempering is a secondary process performed after hardening to reduce that brittleness and increase toughness. It involves reheating the hardened part to a lower temperature to slightly relax the microstructure.

Other related processes, like normalizing or stress relieving, are used to remove internal stresses introduced during manufacturing (like welding or machining), which improves dimensional stability and resistance to fatigue.

Understanding the Trade-offs

Selecting a heat treatment process is always an exercise in balancing competing properties. No single process is perfect for every situation.

The Hardness vs. Toughness Compromise

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness, you almost always decrease its toughness, making it more brittle and susceptible to shattering under impact.

Tempering is the solution to this problem, intentionally sacrificing a small amount of hardness to gain a significant amount of toughness.

The Challenge of Oxidation

As noted in many industrial applications, performing these processes at elevated temperatures in the presence of oxygen is problematic. The oxygen reacts with the hot metal surface.

This can cause undesirable scaling (a flaky oxide layer) or decarburization (the loss of carbon from the surface of steel), which softens the outer layer and defeats the purpose of hardening. For this reason, many heat treatments are performed in controlled-atmosphere furnaces or vacuum furnaces.

The Risk of Distortion and Cracking

Rapid heating and especially rapid cooling (quenching) are thermally violent events. The extreme temperature changes can cause internal stresses that lead to the part warping, distorting, or even cracking, particularly in complex geometries.

Matching the Process to Your Goal

The right choice depends entirely on what you need the final component to do.

- If your primary focus is maximum wear resistance: You will use a hardening process like through-hardening or case hardening, followed by a tempering step to prevent fractures.

- If your primary focus is easy machinability or formability: You will use an annealing process to put the material in its softest possible state before fabrication.

- If your primary focus is the durability and safety of a finished part: You will use tempering to toughen a hardened component or stress relieving to remove internal stresses from manufacturing.

Ultimately, heat treatment transforms a simple metal into a high-performance material engineered for a specific task.

Summary Table:

| Process | Primary Goal | Key Method | Resulting Property |

|---|---|---|---|

| Hardening | Increase Strength & Wear Resistance | Heat + Rapid Quench | High Hardness |

| Annealing | Soften for Machinability | Heat + Slow Cool | High Ductility |

| Tempering | Reduce Brittleness, Increase Toughness | Reheat Hardened Part | Balanced Hardness & Toughness |

Ready to achieve precise material properties for your lab components? KINTEK's advanced lab furnaces provide the exact temperature control and atmosphere management required for successful hardening, annealing, and tempering processes. Whether you're developing wear-resistant tools or stress-relieving complex parts, our equipment ensures consistent, high-quality results without oxidation or distortion. Contact our experts today to find the perfect heat treatment solution for your laboratory's specific metalworking needs!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the difference between hot air oven and muffle furnace? Choose the Right Tool for Your Lab's Thermal Needs

- What is the purpose of a muffle furnace in a lab? Achieve Pure, High-Temperature Heat for Your Materials

- What is the alternative to a laboratory oven? Find the Right Heating Tool for Your Lab

- What is difference between hot air oven and muffle furnace? Key Differences in Temperature and Applications

- What is the main function of the muffle furnace? Achieve Pure, High-Temperature Heating Without Contamination