At its core, the three foundational heat treatments for metals, particularly steel, are annealing, hardening, and tempering. These processes use controlled heating and cooling cycles to fundamentally change a metal's internal structure, allowing you to precisely tailor its mechanical properties for a specific application.

The purpose of heat treatment is not arbitrary; it is a deliberate engineering process to manipulate the trade-off between a material's hardness, toughness, and ductility. Understanding these three core methods gives you control over the final performance of a metal component.

Why Heat Treatment is Essential

Before examining the processes, it's crucial to understand the goal. Heat treatment modifies the microstructure—the arrangement of microscopic crystals or grains—within a metal.

The Microscopic Impact

The size, shape, and composition of these grains directly determine the macroscopic properties we observe, such as strength, machinability, and brittleness.

Controlling Material Performance

By managing temperature, time, and cooling rates, you can force the microstructure into specific configurations, effectively deciding whether the final part will be soft and easy to machine, extremely hard and wear-resistant, or tough and durable.

The Three Foundational Heat Treatments

Each of the three main treatments serves a distinct purpose in the lifecycle of a metal part. They are often used in sequence to achieve a desired balance of properties.

1. Annealing: To Soften and Relieve Stress

Annealing is a process designed to make metal as soft and ductile as possible. It is often performed to make a material easier to machine or form.

The process involves heating the metal above its critical temperature, holding it there to allow the microstructure to fully transform and refine, and then cooling it very slowly. This slow cooling allows the grains to form in a uniform, stress-free state.

2. Hardening: To Increase Strength and Wear Resistance

Hardening is used to make a metal, typically steel, significantly harder and stronger, increasing its resistance to wear and abrasion.

This is achieved by heating the steel above its critical temperature and then cooling it rapidly—a process known as quenching. This rapid cooling traps the carbon atoms in a highly stressed, needle-like crystal structure called martensite, which is extremely hard but also very brittle.

3. Tempering: To Reduce Brittleness and Add Toughness

Tempering is almost always performed immediately after hardening. A hardened part is often too brittle for practical use and could shatter like glass under impact.

The process involves reheating the hardened part to a lower temperature (well below the critical point) and holding it for a specific time. This relieves some of the internal stress from the martensite structure, sacrificing some hardness to gain a significant increase in toughness.

Understanding the Trade-offs

Choosing a heat treatment is never about achieving a single perfect property. It is always a balancing act.

The Hardness vs. Toughness Dilemma

This is the most critical trade-off in heat treatment. Hardness is the resistance to scratching and indentation, while toughness is the ability to absorb energy and deform without fracturing.

Increasing hardness through quenching inevitably reduces toughness, making the material brittle. Tempering is the intentional act of walking back from maximum hardness to regain essential toughness.

The Critical Role of Cooling Rates

The speed at which a metal cools is the primary variable that determines the outcome. A slow cool in the furnace results in a soft, annealed state. A rapid quench in water or oil results in a hard, martensitic state. An intermediate cooling rate, like in open air (normalizing), produces a different set of properties altogether.

Material Composition is Key

Not all metals are equally responsive to heat treatment. For steels, the carbon content is the most important factor. Low-carbon steels cannot be significantly hardened through quenching, while high-carbon and alloy steels are designed specifically for it.

Selecting the Right Treatment for Your Goal

Your choice depends entirely on the intended function of the final component.

- If your primary focus is manufacturability: Anneal the material to make it soft, ductile, and easy to machine, stamp, or form.

- If your primary focus is maximum wear resistance: Harden the component for extreme surface hardness, but be prepared for it to be brittle and only use it in applications without high impact.

- If your primary focus is balanced strength and durability: Use the classic combination of hardening followed by tempering to create a part that is strong, holds an edge, and can withstand operational shock.

By understanding these fundamental processes, you gain direct control over the final performance and reliability of your material.

Summary Table:

| Heat Treatment | Primary Goal | Process Summary | Key Outcome |

|---|---|---|---|

| Annealing | Soften & Relieve Stress | Heat above critical temperature, then cool very slowly. | Soft, ductile, and stress-free material. |

| Hardening | Increase Strength & Wear Resistance | Heat above critical temperature, then quench (cool rapidly). | Very hard but brittle martensitic structure. |

| Tempering | Reduce Brittleness & Add Toughness | Reheat hardened part to a lower temperature, then cool. | Balanced properties: strong, tough, and durable. |

Ready to achieve precise material properties in your lab?

Understanding these heat treatments is the first step. Implementing them consistently requires reliable and accurate equipment. KINTEK specializes in high-performance lab furnaces and ovens designed for precise annealing, hardening, and tempering processes.

Contact our experts today to discuss how our solutions can bring reliability and repeatability to your heat treatment workflows, ensuring your materials meet their exact performance specifications.

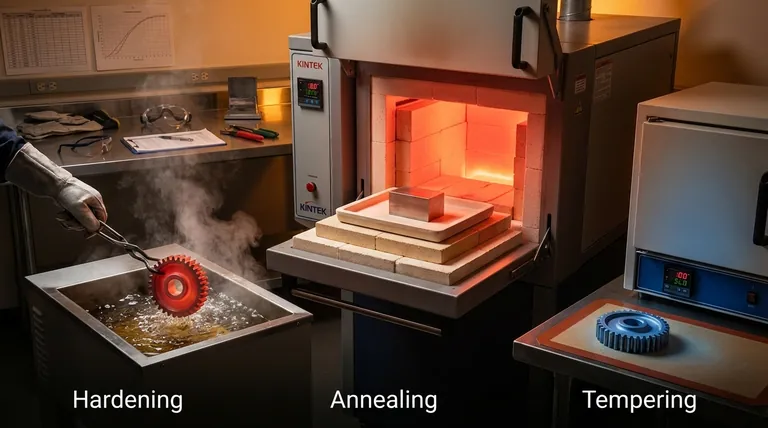

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- How does heat treatment process work? Tailor Material Properties for Your Application