In a ball mill, the most commonly used types of grinding media are stainless steel balls, ceramic balls, and flint pebbles. Each is selected based on its unique material properties, which directly influence the grinding process, efficiency, and the purity of the final product.

The selection of grinding media is not a trivial choice; it is a critical process variable. The ideal medium is determined by balancing the need for grinding efficiency against the acceptable level of product contamination and overall operational cost.

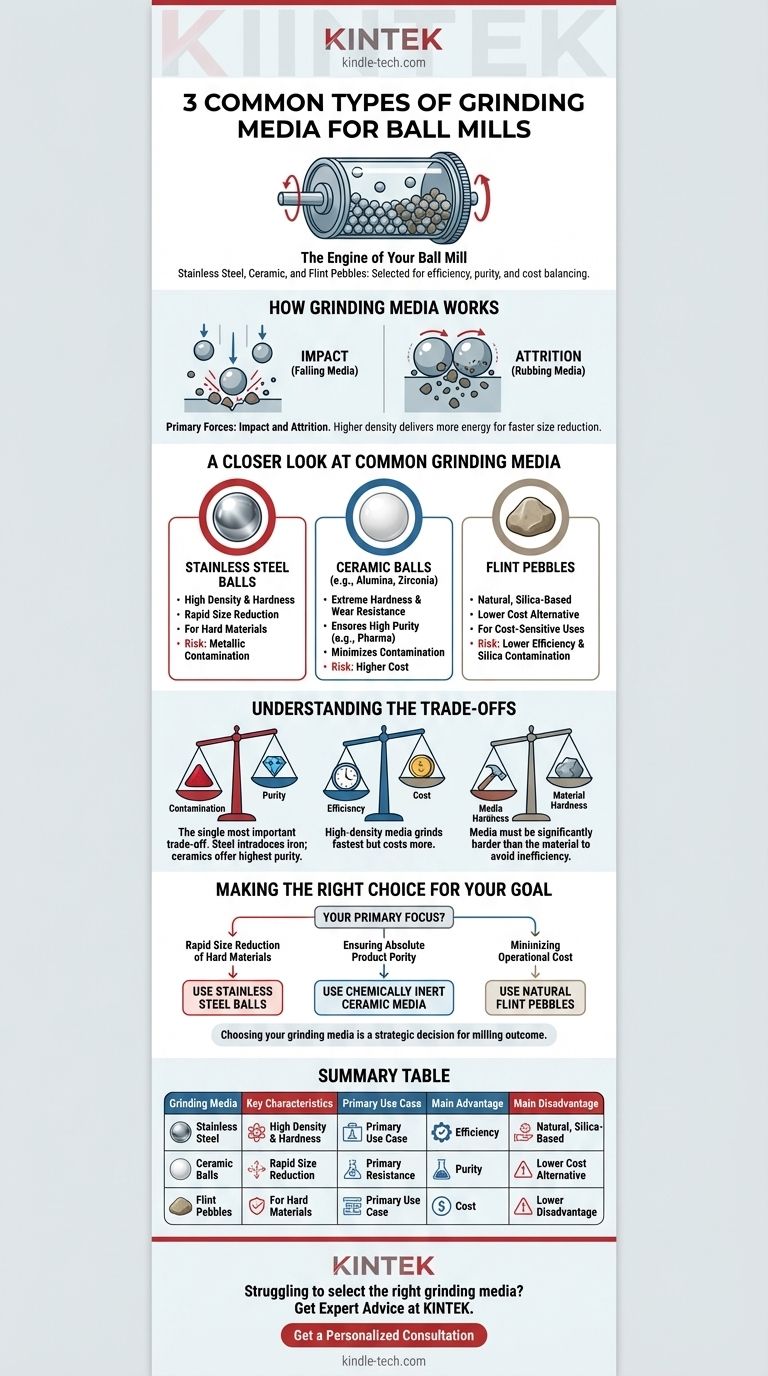

How Grinding Media Works

The Mechanics of Attrition

Grinding media are the engine of a ball mill. As the mill drum rotates, the media are lifted and then cascade or cataract down, creating a powerful grinding action.

This action breaks down particles through two primary forces: impact from the media falling and attrition from the media rubbing against each other and the material.

The Role of Energy and Motion

The kinetic energy of the media is paramount. The velocity and mass of each grinding element dictate the collision energy.

Higher density media, like steel, deliver more impact energy, leading to faster size reduction. Frictional and rubbing forces also contribute significantly to the grinding process, especially for achieving very fine particles.

A Closer Look at Common Grinding Media

Stainless Steel Balls

Stainless steel is a high-density, high-hardness medium. This makes it extremely effective for milling hard materials and for applications where rapid particle size reduction is the primary goal.

Its high mass delivers maximum impact energy upon collision, shattering tough particles efficiently. However, its primary drawback is the potential for metallic contamination.

Ceramic Balls

Ceramic media, such as those made from alumina or zirconia, are valued for their extreme hardness and excellent wear resistance.

This hardness makes them highly durable and, most importantly, minimizes the risk of contaminating the milled product. They are the standard choice in industries like pharmaceuticals, electronics, and specialty chemicals where product purity is non-negotiable.

Flint Pebbles

Flint pebbles are a natural, silica-based grinding medium. They are a lower-cost alternative to engineered media like steel or ceramic balls.

Because they have lower density and less uniform shape, their grinding efficiency is generally lower. They are typically used in applications where cost is a major factor and slight silica contamination is acceptable, such as in certain ceramic glaze preparations.

Understanding the Trade-offs

Contamination vs. Purity

The single most important trade-off is the risk of contamination. All grinding media will wear down over time, introducing small amounts of their own material into your product.

Steel introduces iron, which is unacceptable for many applications. Inert ceramics offer the highest purity but at a higher cost.

Grinding Efficiency vs. Cost

There is a direct relationship between the density of the media and its grinding efficiency. High-density steel grinds fastest but is more expensive and causes more wear on the mill lining.

Low-density, low-cost media like flint pebbles are less efficient, requiring longer milling times to achieve the same result.

Media Hardness vs. Material Hardness

A fundamental principle is that the grinding media must be significantly harder than the material being processed.

Using a softer medium on a hard material will result in the media being ground down instead of the product, leading to extreme contamination and inefficient milling.

Making the Right Choice for Your Goal

Ultimately, the correct media depends entirely on your project's specific requirements.

- If your primary focus is rapid size reduction of hard materials: High-density stainless steel balls provide the necessary impact energy.

- If your primary focus is ensuring absolute product purity: Chemically inert ceramic media is the only reliable choice.

- If your primary focus is minimizing operational cost for less sensitive materials: Natural flint pebbles can be a cost-effective solution.

Choosing your grinding media is a strategic decision that directly controls the outcome of your milling process.

Summary Table:

| Grinding Media | Key Characteristics | Primary Use Case | Main Advantage | Main Disadvantage |

|---|---|---|---|---|

| Stainless Steel Balls | High density, high hardness | Rapid size reduction of hard materials | Maximum grinding efficiency | Risk of metallic contamination |

| Ceramic Balls | Extreme hardness, chemically inert | Applications requiring high purity (pharmaceuticals, electronics) | Excellent product purity | Higher cost |

| Flint Pebbles | Natural, low density, lower cost | Cost-sensitive applications where silica contamination is acceptable | Low operational cost | Lower grinding efficiency |

Struggling to select the right grinding media for your specific material and purity requirements?

The choice of grinding media is a critical variable that directly impacts your product quality, efficiency, and cost. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including a full range of grinding media for ball mills. Our experts can help you navigate the trade-offs between contamination, efficiency, and cost to find the perfect solution for your laboratory's needs.

Contact us today to discuss your application and ensure optimal results for your milling process.

Get a Personalized Consultation

Visual Guide

Related Products

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the primary function of a planetary ball mill in FeCrAl-based powder prep? Achieve High-Energy Mechanical Alloying

- What is the primary function of a planetary ball mill for Fe-Cu composites? Optimize Particle Distribution & Conductivity

- What role does a high-energy planetary ball mill play in Mo-La2O3 alloying? Achieve Superior Microstructure Control