While there are many specific annealing techniques, the question of "two processes" often refers to a simplification of the core goals. In reality, annealing is a single process with three distinct stages, but it is categorized into different types based on the target temperature. The two most fundamental categories that cover the majority of applications are Full Annealing and Process Annealing.

The most critical takeaway is that annealing isn't a set of two distinct processes, but rather a spectrum of heat treatments. The key variable is the target temperature relative to the material's critical transformation points, which dictates the final properties of the metal.

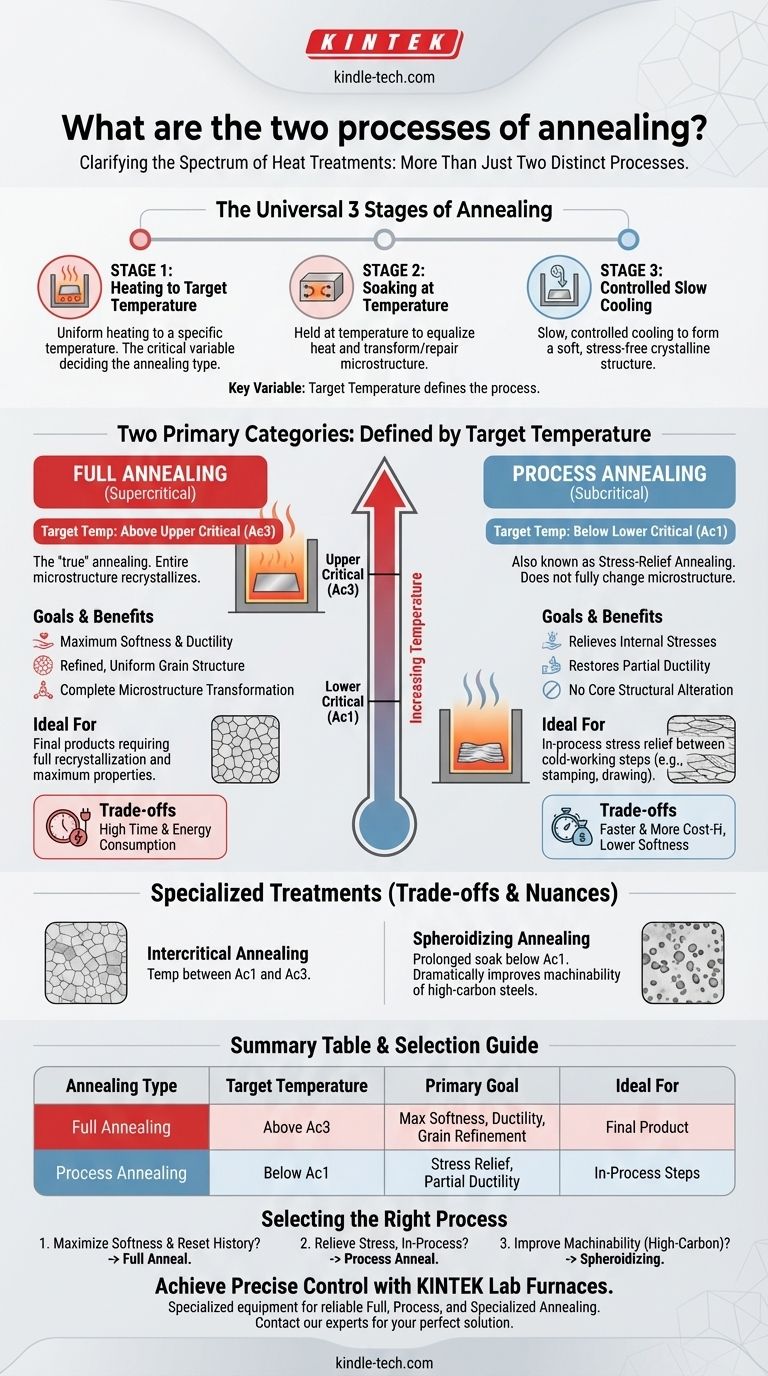

The Universal Stages of Any Annealing Process

Before categorizing annealing into different types, it's essential to understand that every annealing treatment follows the same three fundamental stages. The "type" of annealing is simply a variation in the parameters of these stages, primarily temperature.

Stage 1: Heating to a Target Temperature

The metal is slowly and uniformly heated to a specific, predetermined temperature. This temperature is the most critical variable and determines which type of annealing is being performed.

Stage 2: Soaking at Temperature

Once the target temperature is reached, the metal is held there for a set period. This "soaking" allows the temperature to equalize throughout the material's entire cross-section and enables the internal microstructure to transform and repair defects.

Stage 3: Controlled Slow Cooling

After soaking, the metal is cooled at a very slow and controlled rate, often by leaving it in the furnace and shutting it off. This slow cooling is crucial for forming a soft, ductile, and stress-free crystalline structure.

The Primary Categories of Annealing (The "Why")

The confusion over "two processes" arises from how these stages are applied. The main distinction comes down to how hot the material gets, which is based on its lower (Ac1) and upper (Ac3) critical temperatures.

Full Annealing (Supercritical)

This is often considered the "true" form of annealing. The metal, typically steel, is heated to a temperature above its upper critical temperature (Ac3).

This high temperature causes the entire microstructure to recrystallize into a new, uniform grain structure. The slow cool from this state produces maximum softness, ductility, and a refined grain structure.

Process Annealing (Subcritical)

This method, also known as stress-relief annealing, involves heating the metal to a temperature below its lower critical temperature (Ac1).

Because it doesn't cross the critical temperature threshold, it doesn't fully change the microstructure. Instead, its primary goal is to relieve internal stresses that have built up during cold-working processes like stamping or drawing, restoring some ductility so the part can be worked further.

Intercritical and Spheroidizing Anneals

Between the two main categories lie more specialized treatments. Intercritical annealing heats the metal to a temperature between Ac1 and Ac3.

Spheroidizing is another type of subcritical anneal that uses a prolonged soak just below Ac1 to transform hard iron carbides into small, rounded spheroids, dramatically improving the machinability of high-carbon steels.

Understanding the Trade-offs

Choosing an annealing process involves balancing the desired outcome with practical constraints. There is no single "best" method for all situations.

Time and Energy Consumption

Full annealing is the most time-consuming and energy-intensive process. Heating to a higher temperature and the extremely slow cooling rate required can take many hours or even days for large parts, increasing costs significantly.

Degree of Softness vs. Efficiency

Process annealing is much faster and cheaper than a full anneal. However, it only restores partial ductility and does not refine the grain structure. It is a pragmatic choice for in-process manufacturing steps, not for a final, fully softened product.

Surface Finish and Oxidation

Heating metals to high temperatures in the presence of oxygen causes surface oxidation, or "scale." To prevent this, specific techniques like Bright Annealing are performed in a controlled atmosphere of inert or vacuum gas, but this adds complexity and cost to the process.

Selecting the Right Process for Your Goal

Your choice depends entirely on what you need the material to do next. By understanding the underlying goal, you can select the appropriate method.

- If your primary focus is achieving maximum softness and wiping out the material's prior history: A Full Anneal is the correct choice, as it completely recrystallizes the microstructure.

- If your primary focus is relieving stress between cold-working steps without altering the core structure: A Process (Subcritical) Anneal is the most efficient and cost-effective solution.

- If your primary focus is improving the machinability of a high-carbon steel part: A specialized subcritical treatment like Spheroidizing is the most effective approach.

Ultimately, viewing annealing as a versatile tool defined by temperature allows you to tailor the heat treatment to the precise needs of your project.

Summary Table:

| Annealing Type | Target Temperature | Primary Goal | Ideal For |

|---|---|---|---|

| Full Annealing | Above upper critical (Ac3) | Maximum softness, ductility, and grain refinement | Final product requiring full recrystallization |

| Process Annealing | Below lower critical (Ac1) | Stress relief and partial ductility restoration | In-process stress relief between cold-working steps |

Need precise control over your annealing process? The right lab furnace is critical for achieving accurate temperature profiles and consistent results. KINTEK specializes in high-quality lab furnaces and equipment designed for reliable Full Annealing, Process Annealing, and other specialized heat treatments.

Contact our experts today to find the perfect solution for your laboratory's specific annealing needs and ensure your materials meet the desired properties every time.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab