Crucible furnaces are primarily categorized by their heating source. While they all operate on the simple principle of heating a container (the crucible) to melt material, the method of generating that heat fundamentally divides them into two main types: fuel-fired and electric.

The core decision in selecting a crucible furnace is not about which type is universally superior, but about aligning the heat source—either fuel or electricity—with your specific requirements for temperature control, operating environment, and scale.

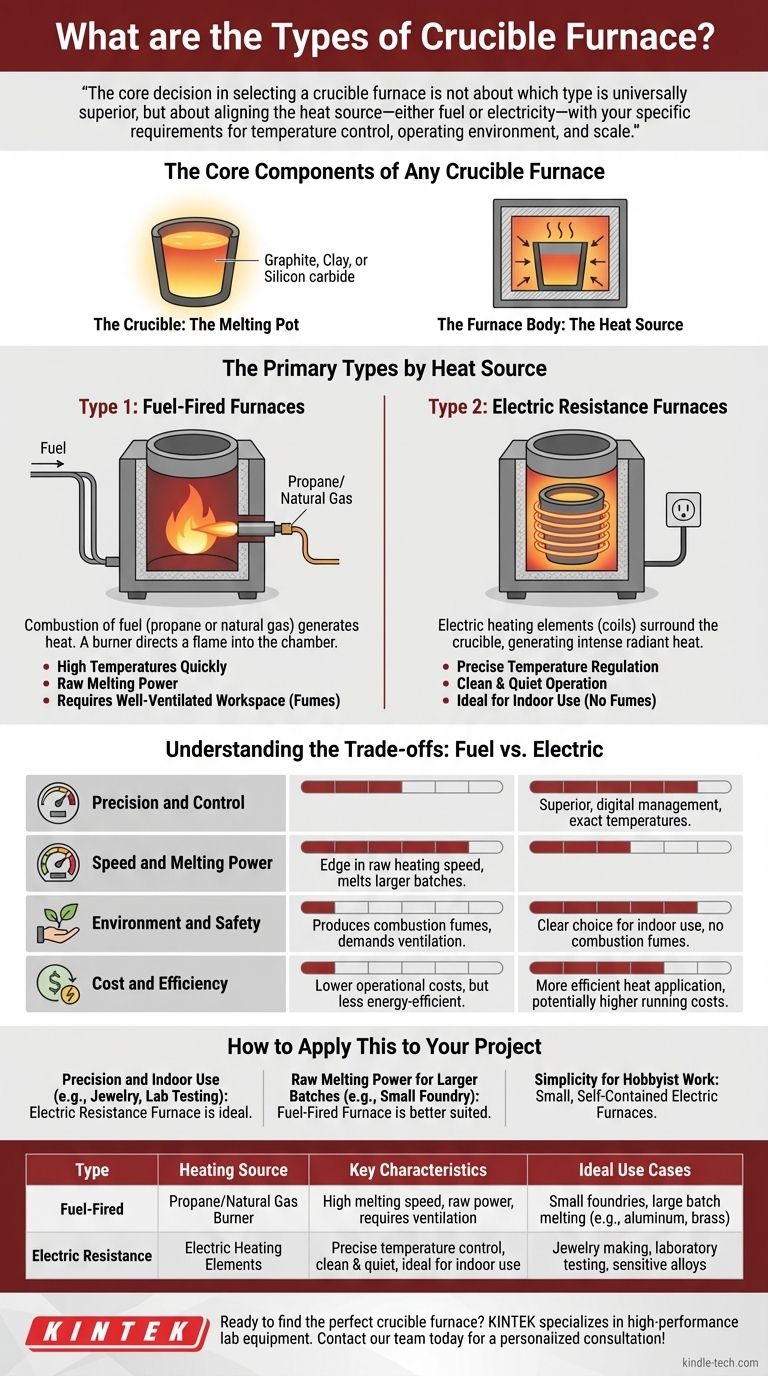

The Core Components of Any Crucible Furnace

Before exploring the types, it's essential to understand the two parts they all share. The interplay between these components defines the furnace's capability.

The Crucible: The Melting Pot

The crucible is the removable container that holds the metal or other material to be melted.

It is made from refractory materials capable of withstanding extreme temperatures, such as graphite, clay, or silicon carbide. The choice of crucible material depends on the metal being melted.

The Furnace Body: The Heat Source

The furnace body is the insulated structure that contains the crucible and the heating system. Its job is to generate immense heat and direct it efficiently toward the crucible.

The Primary Types by Heat Source

The fundamental difference between crucible furnaces lies in how they generate heat. This distinction dictates their performance, ideal use cases, and operational requirements.

Type 1: Fuel-Fired Furnaces

These furnaces use the combustion of a fuel, typically propane or natural gas, to generate heat. A burner directs a powerful flame into the furnace chamber, which then heats the crucible indirectly.

They are known for their ability to reach high temperatures quickly and are often favored for their raw melting power.

Type 2: Electric Resistance Furnaces

These furnaces use electric heating elements (coils) that surround the crucible. When electricity passes through these coils, they glow red hot, generating intense radiant heat.

This method provides exceptionally clean and quiet operation and allows for very precise temperature regulation, which is critical for working with sensitive alloys.

Understanding the Trade-offs: Fuel vs. Electric

Choosing between a fuel-fired and an electric furnace involves a direct comparison of their strengths and weaknesses.

Precision and Control

Electric furnaces offer superior temperature control. The ability to digitally manage the power output to the heating elements allows for holding materials at exact temperatures, which is crucial for laboratory work and complex jewelry casting.

Speed and Melting Power

Fuel-fired furnaces often have an edge in raw heating speed. The intense heat from a gas burner can melt larger batches of metal like aluminum, brass, or bronze more quickly than a comparable electric model.

Environment and Safety

Electric furnaces are the clear choice for indoor use in smaller workshops or labs. They produce no combustion fumes, requiring less extensive ventilation.

Fuel-fired furnaces produce carbon monoxide and other byproducts, demanding a well-ventilated workspace or outdoor operation to ensure safety.

Cost and Efficiency

Crucible furnaces, in general, are not highly energy-efficient. Fuel-fired models may have lower operational costs depending on local gas prices, while electric furnaces, though potentially more expensive to run, apply their heat more efficiently within the insulated chamber.

How to Apply This to Your Project

Your specific application is the most important factor in determining the right type of furnace.

- If your primary focus is precision and indoor use: An electric resistance furnace is the ideal choice for tasks like jewelry making or lab testing.

- If your primary focus is raw melting power for larger batches: A fuel-fired furnace is better suited for small foundry operations where speed and volume are key.

- If your primary focus is simplicity for hobbyist work: Small, self-contained electric furnaces are often easier for beginners to set up and operate safely.

Understanding how a furnace generates its heat is the first and most critical step in selecting the right tool for your work.

Summary Table:

| Type | Heating Source | Key Characteristics | Ideal Use Cases |

|---|---|---|---|

| Fuel-Fired | Propane/Natural Gas Burner | High melting speed, raw power, requires ventilation | Small foundries, large batch melting (e.g., aluminum, brass) |

| Electric Resistance | Electric Heating Elements | Precise temperature control, clean & quiet, ideal for indoor use | Jewelry making, laboratory testing, sensitive alloys |

Ready to find the perfect crucible furnace for your project?

KINTEK specializes in high-performance lab equipment, including crucible furnaces for both industrial and research applications. Whether you need the raw power of a fuel-fired model or the precise control of an electric furnace, our experts can help you select the right equipment to enhance your efficiency and results.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of alumina crucibles in Na3V2(PO4)2F3 synthesis? Ensure Purity in NVPF Production

- What are the advantages of using a silicon carbide crucible? Achieve Peak Purity for Zinc-Lead Alloy Melting

- Why Use Glassy Carbon Crucibles for Geological Fusion? Ensure High-Purity Trace Zirconium Analysis Results

- What is the difference between graphite and clay crucible? A Guide to Choosing the Right Crucible for Your Lab

- What is the maximum temperature for a porcelain crucible? Avoid Cracking and Contamination

- What factors influence the selection of high-purity alumina crucibles or graphite boats for W-Cu infiltration?

- What are modern crucibles made of? A Guide to Materials for High-Temperature Applications

- What is the best crucible for melting gold? Choose the Right Crucible for Safety & Purity