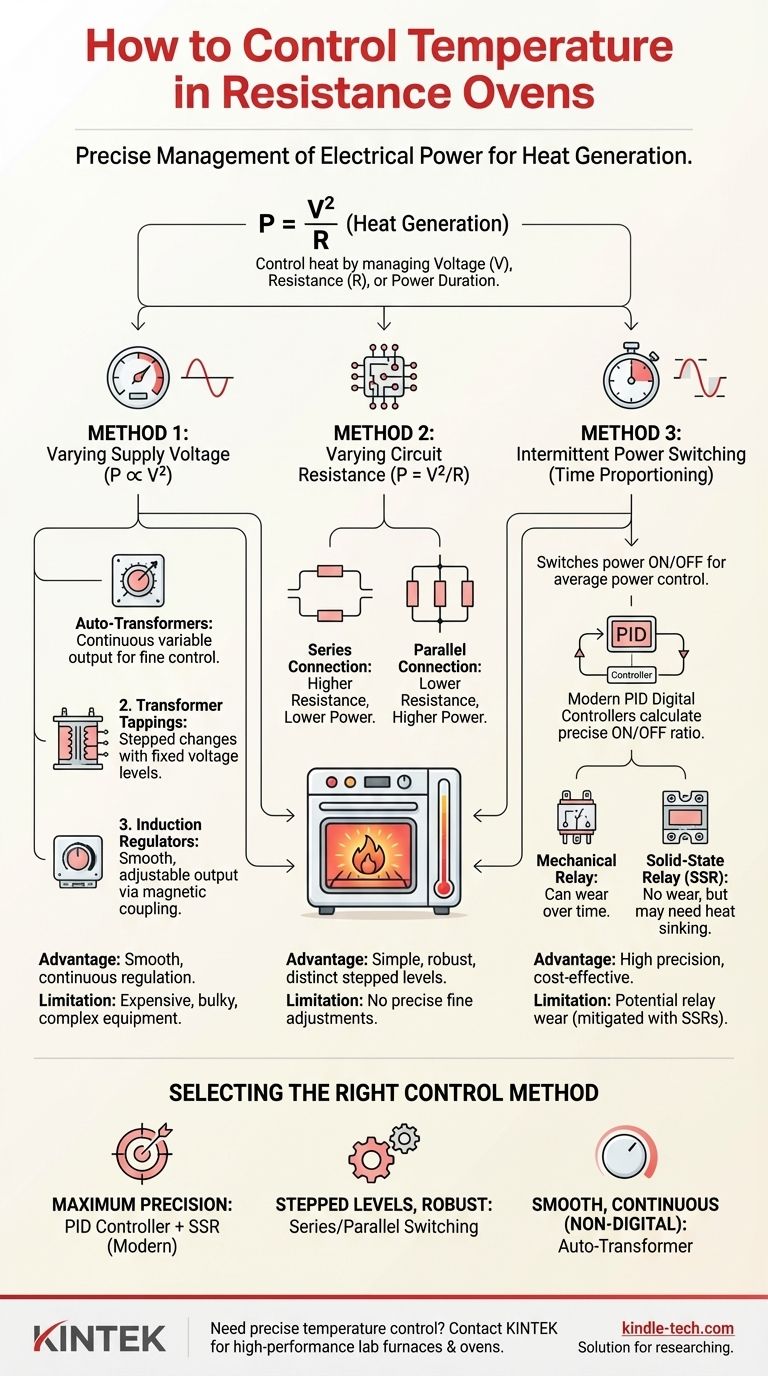

Controlling the temperature in a resistance oven is a matter of precisely managing the electrical power that generates heat. This is achieved through three primary methods: varying the supply voltage to the heating elements, changing the electrical resistance of the heating circuit, or adjusting the on-off duty cycle of the power supply.

At its core, temperature control is about managing heat generation, which follows the electrical law P = V²/R. By manipulating the voltage (V), resistance (R), or the duration the power is applied, you gain direct control over the oven's thermal output and its internal temperature.

The Three Pillars of Temperature Control

The heat produced in a resistance oven is a direct result of I²R losses, where electrical energy is converted into thermal energy. All control methods work by manipulating the variables in this power equation.

Method 1: Varying the Supply Voltage

Since power is proportional to the square of the voltage (P ∝ V²), small adjustments to the voltage can produce significant changes in heat output. This allows for smooth and continuous temperature regulation.

This is typically accomplished in one of three ways:

- Auto-Transformers: These devices provide a continuously variable output voltage from a fixed input, offering very fine control over the power delivered.

- Transformer Tappings: A transformer with multiple output connections ("taps") allows you to select from several fixed voltage levels, providing stepped changes in heat output.

- Induction Regulators: This older method functions like a transformer where the magnetic coupling can be varied, resulting in a smooth, adjustable output voltage.

Method 2: Varying the Circuit Resistance

By reconfiguring how the heating elements are connected, you can change the total resistance of the circuit and thus alter the power dissipation (P = V²/R).

The most common approach is to switch the heating elements between a series and parallel configuration. Connecting elements in series increases the total resistance, leading to lower power output. Switching them to parallel decreases the total resistance, maximizing heat generation. This method provides distinct, stepped levels of heat (e.g., low, medium, high).

Method 3: Intermittent Power Switching (Time Proportioning)

This method involves switching the power supply to the heating elements on and off for short, controlled periods. It does not change the instantaneous power, but it changes the average power delivered over time.

Think of it like rapidly flicking a light switch to achieve a level of brightness between fully on and fully off. Modern digital temperature controllers excel at this, using a PID (Proportional-Integral-Derivative) algorithm to calculate the precise on/off ratio needed to hold a set temperature. The actual switching is performed by a mechanical relay or a Solid-State Relay (SSR).

Understanding the Trade-offs

Each control method has distinct advantages and disadvantages. Choosing the right one depends on the requirements for precision, cost, and equipment longevity.

Voltage Control: Precision vs. Complexity

Voltage control offers the potential for very smooth and continuous power adjustment.

However, the equipment required, such as large auto-transformers or induction regulators, can be expensive, bulky, and mechanically complex, making it less common in modern, smaller ovens.

Resistance Control: Simplicity vs. Granularity

Altering the circuit resistance is a robust and electrically simple method. It doesn't require sophisticated control electronics.

The major limitation is that it only provides a few fixed heat levels. It is not suitable for applications that require holding a precise temperature, as it cannot make fine adjustments.

Time-Based Control: Cost-Effectiveness vs. Component Wear

This is the most common method in modern ovens due to its high precision and low cost, as it can be managed by inexpensive microcontrollers.

Its primary trade-off is component wear. Frequent switching can wear out mechanical relays over time. Using a Solid-State Relay (SSR) eliminates this issue but can be more expensive and may require heat sinking.

Making the Right Choice for Your Application

Your selection should be guided by your operational goals for precision, budget, and scale.

- If your primary focus is maximum precision and responsiveness: Use a modern digital controller employing time-proportioning control with a Solid-State Relay (SSR).

- If your primary focus is stepped power levels in a simple, robust system: Use variable resistance by reconfiguring heating elements between series and parallel.

- If your primary focus is smooth, continuous power adjustment without digital switching: Use an auto-transformer, accepting the higher initial cost and physical size.

By understanding these core principles, you can select the control strategy that delivers the most reliable and efficient performance for your specific heating task.

Summary Table:

| Control Method | How It Works | Key Advantage | Key Limitation |

|---|---|---|---|

| Varying Supply Voltage | Adjusts voltage to change power (P ∝ V²) | Smooth, continuous regulation | Expensive, bulky equipment |

| Varying Circuit Resistance | Switches heating elements between series/parallel | Simple, robust design | Only provides stepped heat levels |

| Intermittent Power Switching (Time-Proportioning) | Switches power on/off to control average power | High precision, cost-effective | Can cause relay wear (mitigated with SSRs) |

Need precise temperature control for your lab's heating processes? KINTEK specializes in high-performance lab furnaces and ovens with advanced control systems. Our experts can help you select the right equipment—whether you need the precision of PID control with SSRs or the robustness of a simple resistance-switching system—to ensure reliable and efficient results for your laboratory. Contact our team today to discuss your specific application!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is the function of a laboratory drying oven in Zr2.5Nb alloy pretreatment? Ensure Precise Corrosion Test Results

- What is the role of a laboratory drying oven in catalyst treatment? Ensure Structural Integrity & High Performance

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results

- How does a laboratory constant temperature drying oven contribute to the processing of synthesized Zinc Oxide precipitates?

- Why is a forced-air drying oven required for ZnS powder? Protect Sintered Ceramics from Cracking