At its core, heat treatment is a group of industrial processes used to intentionally alter the physical, and sometimes chemical, properties of a material. The primary processes can be broadly categorized into four main types: annealing, which softens a material; hardening, which increases its strength; tempering, which reduces brittleness after hardening; and case hardening, which hardens only the surface. These processes achieve their results by using controlled heating and cooling to manipulate the material's internal microstructure.

The specific type of heat treatment chosen is not arbitrary; it is a precise engineering decision designed to solve a fundamental trade-off. Each process targets a specific balance between properties like hardness, toughness, and ductility to meet the demands of a final application.

The Goal: Engineering a Material's Microstructure

Heat treatment is not simply about making metal hot or cold. It's a highly controlled metallurgical process designed to change the material's internal crystal structure, known as its microstructure.

Think of a metal's microstructure as its internal architecture. By precisely applying and removing thermal energy, you can rearrange this architecture to produce entirely different performance characteristics from the exact same piece of metal.

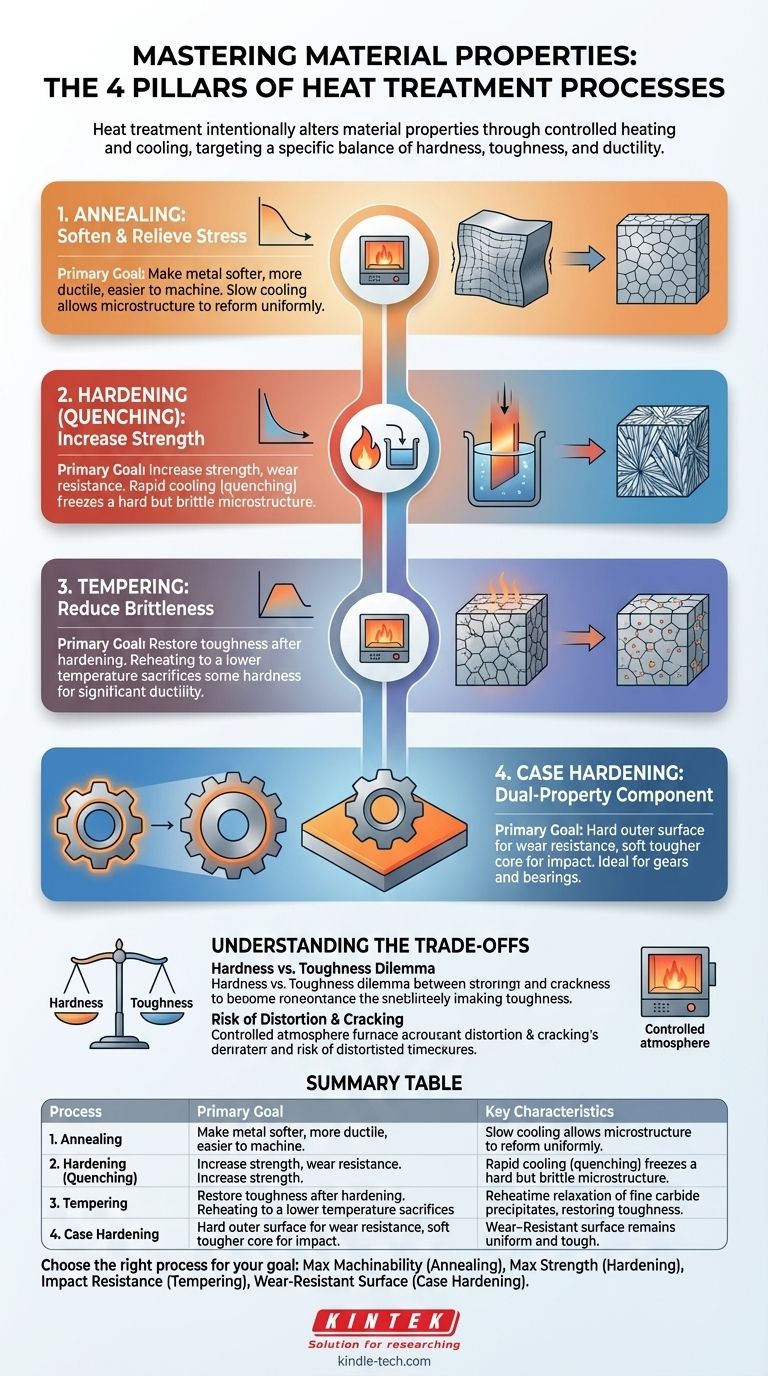

The Four Pillars of Heat Treatment

While there are many specific recipes, nearly all heat treatment processes fall into one of four fundamental categories, each with a distinct objective.

1. Annealing: To Soften and Relieve Stress

The primary goal of annealing is to make a metal softer, more ductile, and easier to machine or form. It also serves to relieve internal stresses that may have built up during prior manufacturing steps like forging or casting.

The process involves heating the material to a specific temperature, holding it there for a period, and then allowing it to cool very slowly. This slow cooling allows the internal crystal structure to reform in a uniform, low-stress state.

2. Hardening (Quenching): To Increase Strength

Hardening is used to increase a metal's strength, wear resistance, and ability to hold a sharp edge. It is the process that makes tools, bearings, and gears durable.

This is achieved by heating the material to a critical temperature where its crystal structure changes, and then cooling it rapidly. This rapid cooling, called quenching, freezes a hard but brittle microstructure in place. Common quenching media include water, oil, or air.

3. Tempering: To Reduce Brittleness

A material that has been hardened is often too brittle for practical use; it might shatter under impact. Tempering is a secondary process performed after hardening to restore some toughness.

The part is reheated to a lower temperature, held for a specific time, and then cooled. This process strategically sacrifices a small amount of hardness to gain a significant increase in toughness, relieving the internal stresses created during quenching.

4. Case Hardening: For a Dual-Property Component

Case hardening, or surface hardening, creates a component with two distinct sets of properties: an extremely hard, wear-resistant outer surface (the "case") and a softer, tougher, more ductile inner core.

This is ideal for parts like gears, which need to resist surface wear while also withstanding shock and impact without cracking. This is often done by diffusing elements like carbon (carburizing) or nitrogen (nitriding) into the surface of the steel at high temperatures.

Understanding the Inherent Trade-offs

Choosing a heat treatment process requires understanding the compromises involved. You are always balancing one property against another.

The Hardness vs. Toughness Dilemma

The most fundamental trade-off in metallurgy is between hardness and toughness.

Increasing a material's hardness almost invariably makes it more brittle (less tough). Tempering is the primary method for navigating this compromise, allowing engineers to dial in the precise balance required for an application.

The Risk of Distortion and Cracking

The rapid cooling required for hardening introduces significant internal stress. This can cause a part to warp, distort, or even crack if the process is not carefully controlled.

Factors like the part's geometry, the type of steel, and the quench rate must be managed to prevent these defects.

The Critical Role of Atmosphere Control

Many heat treatment processes occur in furnaces with a controlled atmosphere. This is not an afterthought; it is essential for process integrity.

An uncontrolled atmosphere can lead to oxidation (scaling) or the loss of carbon from the surface (decarburization), both of which compromise the final properties of the component. Specialized gas mixtures are used to protect the material and ensure the desired chemical reactions occur.

Making the Right Choice for Your Goal

Your selection of a heat treatment process should be driven by the primary performance requirement of the final part.

- If your primary focus is maximum machinability and formability: Choose a full annealing process to create the softest and most uniform material condition.

- If your primary focus is maximum wear resistance and strength: Choose a hardening process, followed by a low-temperature temper to relieve stress without sacrificing significant hardness.

- If your primary focus is impact resistance and durability: Choose hardening followed by a higher-temperature temper to trade more hardness for a significant gain in toughness.

- If your primary focus is a wear-resistant surface with a shock-resistant core: Choose a case hardening process like carburizing or nitriding.

Ultimately, heat treatment transforms a simple material into a high-performance component engineered for a specific purpose.

Summary Table:

| Process | Primary Goal | Key Characteristics |

|---|---|---|

| Annealing | Soften material, relieve stress | Heated then cooled slowly; improves ductility and machinability |

| Hardening | Increase strength and wear resistance | Heated then quenched rapidly; creates a hard, brittle structure |

| Tempering | Reduce brittleness after hardening | Reheated to a lower temperature; increases toughness |

| Case Hardening | Harden surface while keeping core tough | Diffuses elements (e.g., carbon) into surface; ideal for gears and bearings |

Need precise heat treatment for your lab materials? KINTEK specializes in lab equipment and consumables, offering solutions that ensure accurate temperature control and atmosphere management for annealing, hardening, tempering, and case hardening processes. Our expertise helps you achieve the perfect balance of hardness, toughness, and durability for your specific application. Contact us today to discuss how we can support your laboratory's heat treatment needs!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- Why is air and water vapor introduced during pre-oxidation? Master Surface Passivation for Coking Experiments

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- Does melting require increase in temperature? Understanding Latent Heat and Phase Changes

- What are the four steps to the heat treating process? Master the 3 Core Stages for Superior Results

- What should be considered when performing melting point determination? Ensure Accurate Compound Identification and Purity Assessment