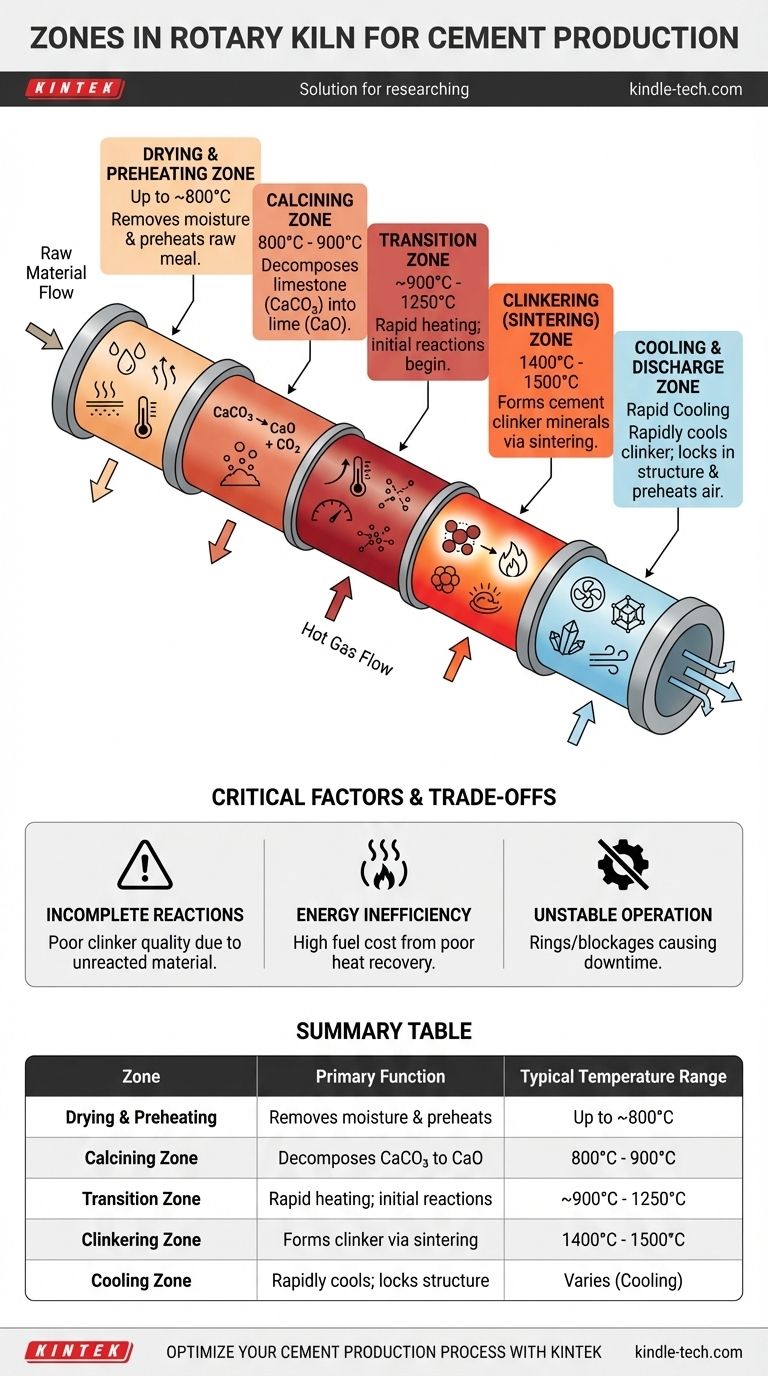

To understand a cement rotary kiln, you must view it as a long, multi-stage chemical reactor, not just a furnace. Based on the flow of material, the primary zones are the preheating zone, the calcining zone, the transition zone, and the clinkering (or sintering) zone, followed by cooling and discharge. Each zone maintains a specific temperature profile to trigger a distinct and necessary chemical reaction in the production of cement clinker.

The core principle is that a rotary kiln is not a single heating chamber, but a sequential process line. It systematically prepares and transforms raw materials through carefully controlled thermal zones to ensure the final chemical reactions create high-quality cement clinker efficiently.

The Journey of Raw Material: A Zone-by-Zone Breakdown

As the raw mix travels down the inclined, rotating kiln, it passes through several distinct thermal environments. Each zone is engineered to perform a specific task in the transformation from raw meal to finished clinker.

The Drying and Preheating Zone

This is the first section the raw material enters at the upper end of the kiln. Its primary function is to remove any remaining free water from the mix.

Hot gases flowing from the hotter zones further down the kiln heat the material to several hundred degrees Celsius, preparing it for the next critical stage. In modern dry-process kilns, much of this work is done in a separate preheater tower before the material even enters the kiln itself.

The Calcining Zone

This zone is where the first major chemical transformation occurs, typically at temperatures between 800°C and 900°C.

Here, the limestone (calcium carbonate, CaCO₃) in the raw mix decomposes, releasing carbon dioxide (CO₂) and leaving behind calcium oxide (CaO), or lime. This step is a massive energy sink, consuming a significant portion of the kiln's total fuel input.

The Transition Zone

After calcination, the material moves through a transition zone where the temperature rapidly increases.

This section acts as a bridge, ensuring the material is sufficiently heated before it enters the most intense part of the kiln. Some initial reactions between the lime and other minerals begin to occur here.

The Clinkering (Sintering) Zone

This is the heart of the kiln and the hottest section, with temperatures reaching 1400°C to 1500°C.

In this zone, the calcium oxide reacts with the silica, alumina, and iron oxide in the mix to form the final crystalline compounds that give cement its strength. This process of fusion is known as sintering, and the resulting nodular product is called clinker.

The Cooling and Discharge Zone

As the white-hot clinker exits the kiln, it enters a specialized cooler. Rapid cooling is essential to lock in the desired crystalline structure of the clinker minerals. This process also preheats the combustion air for the kiln, recovering a significant amount of energy.

Understanding the Trade-offs and Critical Factors

Controlling these zones is a complex balancing act. A failure to maintain the distinct profile of each zone directly impacts efficiency, cost, and the final quality of the cement.

Incomplete Reactions

If material moves through the calcining zone too quickly or at too low a temperature, not all the CaCO₃ will decompose. This unreacted material enters the clinkering zone, disrupting the delicate chemistry and resulting in poor-quality clinker.

Energy Inefficiency

The zoned system is designed for maximum heat recovery. Hot exhaust gas from the clinkering zone must be used to preheat and calcine the incoming raw meal. Poor sealing or improper airflow means this heat is wasted, driving up fuel consumption dramatically.

Unstable Kiln Operation

Poor control over the temperature profile in any single zone can lead to operational problems. These include the formation of large rings or blockages inside the kiln, which can force a complete shutdown for manual removal, leading to significant downtime and lost production.

Making the Right Choice for Your Goal

Understanding the function of each zone is essential for anyone involved in cement production, from plant operators to process engineers.

- If your primary focus is operational efficiency: Pay closest attention to the energy balance between the calcining and clinkering zones, as this is the key to minimizing fuel costs.

- If your primary focus is product quality: The temperature and residence time in the clinkering zone are the most critical variables for ensuring the complete formation of the desired cement minerals.

- If your primary focus is troubleshooting: Analyze which zone is deviating from its target parameters to quickly diagnose issues like blockages, inefficient combustion, or poor clinker chemistry.

Ultimately, the zoned design transforms a simple kiln into a precise and efficient chemical engineering instrument.

Summary Table:

| Zone | Primary Function | Typical Temperature Range |

|---|---|---|

| Drying & Preheating | Removes moisture and preheats raw meal | Up to ~800°C |

| Calcining Zone | Decomposes limestone (CaCO₃) into lime (CaO) | 800°C - 900°C |

| Transition Zone | Rapidly heats material; initial reactions begin | ~900°C - 1250°C |

| Clinkering Zone | Forms cement clinker minerals via sintering | 1400°C - 1500°C |

| Cooling Zone | Rapidly cools clinker to lock in mineral structure | Varies (Cooling) |

Optimize Your Cement Production Process with KINTEK

Understanding the precise thermal zones of your rotary kiln is the first step toward maximizing efficiency and ensuring superior clinker quality. KINTEK specializes in providing high-performance laboratory equipment and consumables essential for analyzing raw materials, monitoring process conditions, and testing final product quality.

Whether you are focused on operational efficiency, product quality, or troubleshooting, our solutions deliver the accuracy and reliability your laboratory needs to support a world-class cement production operation.

Ready to enhance your process control and product quality? Contact our experts today to discuss how KINTEK's lab equipment can meet your specific cement production challenges.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What furnace is used for calcination? A Guide to Muffle, Rotary Kiln, and Shaft Furnaces

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results

- What is the most suitable temperature for burning of cement in rotary kiln? Achieve Perfect Clinker at 1450°C

- What is the pyrolysis process? A Sustainable Solution for Waste Conversion

- What is temperature controlled pyrolysis? Master Heat to Turn Waste into Fuel, Char, or Gas

- What is the historical origin and evolution of the rotary kiln? From 1885 Patent to Modern Industrial Giant

- What are the factors affecting calcination? Master Temperature, Time, Atmosphere & Material Properties

- What can be used for pyrolysis? Turning Organic Waste into Valuable Resources