In short, a vacuum press is a versatile tool for laminating, veneering, and forming materials. It excels at applying perfectly uniform pressure across large or complex curved surfaces, making it ideal for advanced woodworking, artistic mounting, and specialized craft projects where traditional clamps would be impractical or ineffective.

The core function of a vacuum press is not suction, but using atmospheric pressure to clamp objects together with perfectly even force. This capability allows you to create high-quality bonds and forms that are impossible to achieve with mechanical clamps alone.

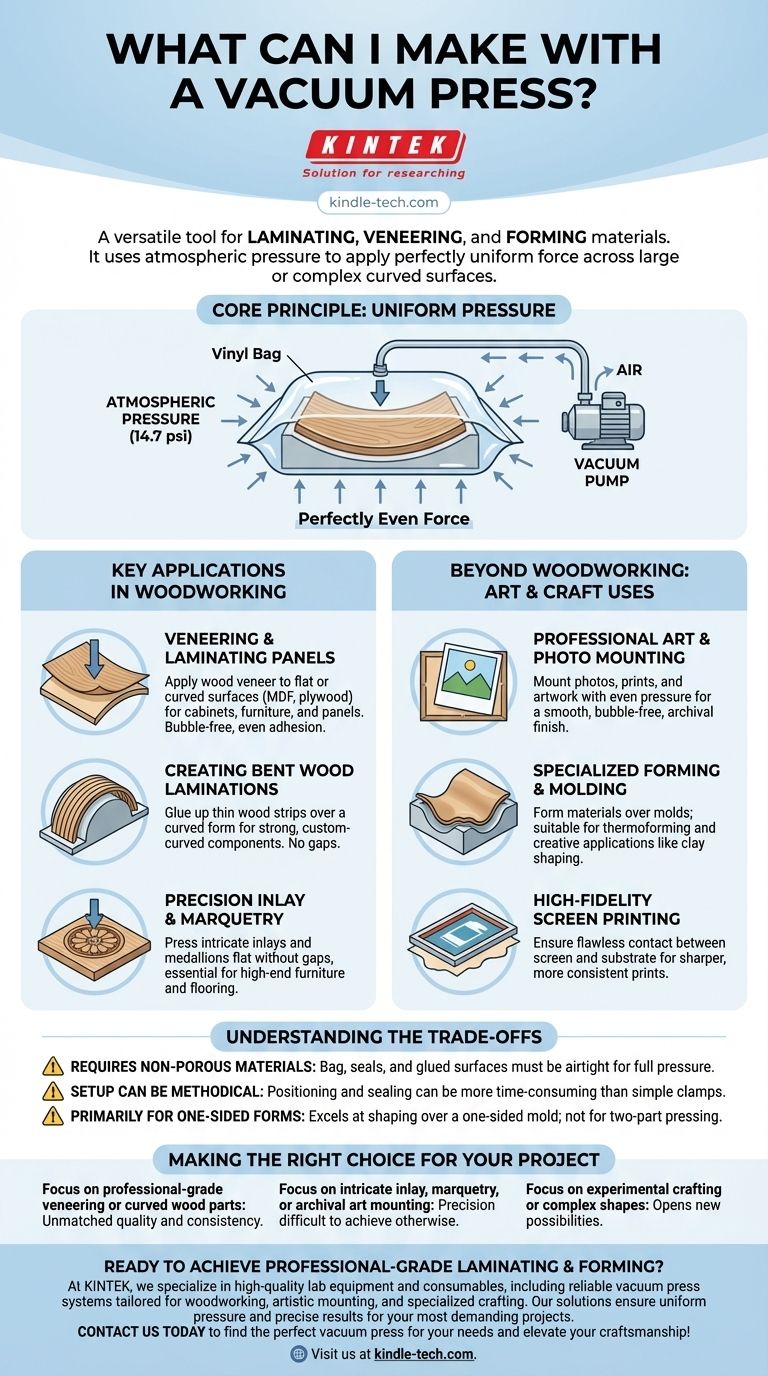

The Core Principle: Uniform Pressure

How It Works

A vacuum press uses a pump to remove air from a sealed vinyl or polyurethane bag. Once the air is evacuated, the outside atmospheric pressure (about 14.7 psi at sea level) exerts immense, even force on everything inside the bag.

This process presses layers of material together or shapes a single flexible material over a mold. The result is a flawless bond or form without the risk of gaps, bubbles, or uneven pressure points common with mechanical clamps.

Key Applications in Woodworking

Veneering and Laminating Panels

This is the most common use for a vacuum press. It's the industry-standard method for applying wood veneer to flat or curved substrates like MDF or plywood to create cabinet doors, furniture components, and architectural panels.

Creating Bent Wood Laminations

By gluing up thin strips of wood (laminates) over a curved form inside the press, you can create strong, custom-curved components. This is essential for projects like curved furniture parts, arched door frames, and custom staircase stringers.

Precision Inlay and Marquetry

A vacuum press ensures that intricate veneer inlays and medallions are pressed flat and securely into the substrate without any gaps. This is critical for high-end furniture and custom flooring projects, where precision is paramount.

Beyond Woodworking: Artistic and Craft Uses

Professional Art and Photo Mounting

The even pressure of a vacuum press is perfect for mounting photographs, prints, and artwork to a backing board. It guarantees a smooth, bubble-free finish that protects the integrity of the piece.

Specialized Forming and Molding

The press can be used to form materials over a mold. While commonly used with heated plastics (thermoforming), it can also be adapted for creative applications like shaping clay components for pottery or other unique artistic forms.

High-Fidelity Screen Printing

In some professional screen printing setups, a vacuum press is used to hold the material perfectly flat and ensure flawless contact between the screen and the substrate. This results in sharper, more consistent prints.

Understanding the Trade-offs

Requires Non-Porous Materials

For the vacuum to work, the bag, seals, and glued surfaces must be airtight. Porous materials or leaky setups will prevent the pump from achieving full pressure, compromising the clamp.

Setup Can Be Methodical

While powerful, using a vacuum press requires careful setup. You must position the workpiece, form, and adhesive correctly inside the bag before sealing it and drawing the vacuum. This process can be more time-consuming than using simple clamps for small, flat projects.

Primarily for One-Sided Forms

When used for forming, a vacuum press excels at shaping a material over a one-sided mold. It is not a substitute for a two-part press that applies pressure from both sides simultaneously.

Making the Right Choice for Your Project

- If your primary focus is professional-grade veneering or creating curved wood parts: A vacuum press is the definitive tool for the job, offering unmatched quality and consistency.

- If your primary focus is intricate inlay, marquetry, or archival art mounting: The uniform pressure provides a level of precision and perfection that is difficult to achieve by other means.

- If your primary focus is experimental crafting or small repairs: While capable, a vacuum press may be overkill; however, it opens up a range of possibilities for complex shapes that no other tool can offer.

Ultimately, a vacuum press empowers you to execute complex laminating and forming tasks with absolute precision.

Summary Table:

| Application | Primary Use | Key Benefit |

|---|---|---|

| Veneering & Laminating | Applying veneer to flat/curved panels | Bubble-free, even adhesion |

| Bent Wood Laminations | Creating curved furniture parts | Strong, custom shapes without gaps |

| Inlay & Marquetry | Precision wood inlay work | Flawless, gap-free intricate designs |

| Art & Photo Mounting | Mounting prints to backing boards | Smooth, archival-quality finish |

| Forming & Molding | Shaping materials over molds | Ideal for complex, one-sided forms |

Ready to achieve professional-grade laminating and forming?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including reliable vacuum press systems tailored for woodworking, artistic mounting, and specialized crafting. Our solutions ensure uniform pressure and precise results for your most demanding projects.

Contact us today to find the perfect vacuum press for your needs and elevate your craftsmanship!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- How does the programmable temperature control of a vacuum hot press furnace benefit the reactive synthesis of TiAl?

- How does high-precision pressure control of a vacuum hot press furnace influence graphite/copper composites?

- What physical conditions are provided by the Hot Press Technique? Master TlBr Crystal Development with Precision

- What are the functions of hydraulic pressure in diffusion bonding? Master Superior Composite Material Integration

- How does a vacuum hot-press furnace facilitate the densification of boron carbide ceramics? Achieve Maximum Density.

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- Why is the rapid cooling of a Hot Isostatic Press (HIP) important for Li4SiO4 electrolytes? Unlock High Performance

- What role does a Hot Isostatic Pressing (HIP) furnace play in processing ATO? Achieve Maximum Density & Conductivity