At its core, furnace cleaning is the targeted maintenance of the individual components inside your furnace unit. This process focuses specifically on parts critical to performance and safety, including the heat exchanger, blower motor, combustion chamber, burners, and fan assembly. Technicians use a combination of high-pressured air and industrial vacuums to remove accumulated dust, soot, and debris.

The crucial distinction to understand is that furnace cleaning is not a superficial task. It is a precise technical service aimed at ensuring the efficiency, longevity, and safe operation of your heating system's most vital internal parts.

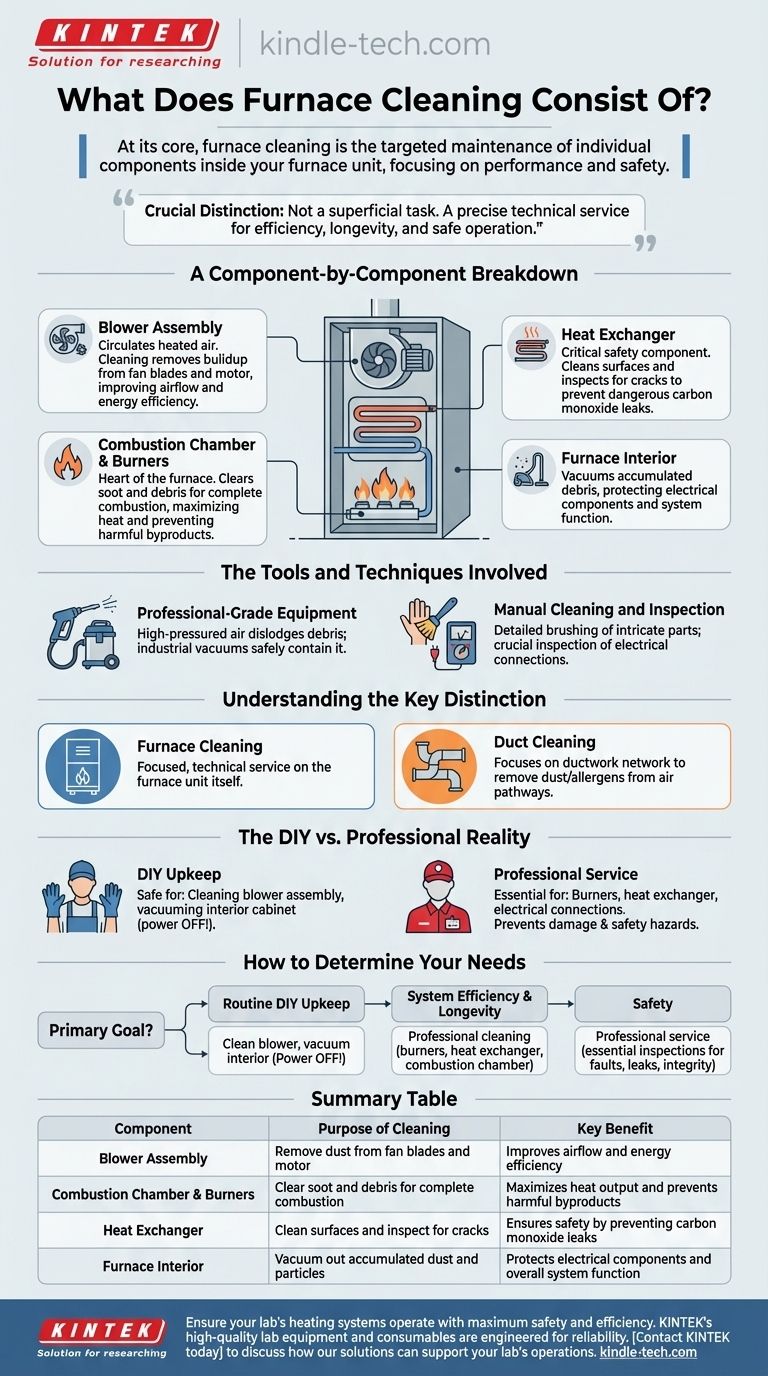

A Component-by-Component Breakdown

To understand the value of a furnace cleaning, it's essential to know what each key component does and why its cleanliness matters.

The Blower Assembly

The blower assembly, which includes the fan, motor, belts, and pulleys, is responsible for circulating heated air throughout your home. Buildup on the fan blades reduces airflow, forcing the motor to work harder and consume more energy.

A thorough cleaning involves removing the fan unit, carefully washing the blades with a non-toxic cleaner, and wiping down all associated parts.

The Combustion Chamber & Burners

This is the heart of your furnace, where fuel is burned to generate heat. Soot and other debris can accumulate on the burners, leading to inefficient combustion.

Cleaning this area ensures the fuel burns cleanly and completely, maximizing heat output and preventing the release of harmful byproducts.

The Heat Exchanger

The heat exchanger is a critical safety component. It transfers heat from the combustion process into the air that gets circulated through your home, while keeping toxic exhaust gases safely sealed away.

A clean heat exchanger allows for maximum heat transfer, improving efficiency. More importantly, the cleaning process often includes an inspection to check for cracks or damage that could lead to dangerous carbon monoxide leaks.

The Furnace Interior

Over time, debris like iron oxide, dust, and other particles can settle inside the furnace cabinet. A comprehensive service includes vacuuming and wiping down this interior.

This prevents debris from being drawn into the blower assembly or interfering with electrical components.

The Tools and Techniques Involved

The effectiveness of a furnace cleaning depends heavily on the methods and equipment used.

Professional-Grade Equipment

Professionals utilize equipment that is far more powerful than standard household tools. High-pressured air dislodges stubborn debris from tight crevices, while industrial-grade vacuums safely contain and remove it from the system.

Manual Cleaning and Inspection

Beyond powerful tools, the process requires detailed manual work. Technicians use brushes to scrub fan blades and other intricate parts.

Critically, this is also a time for inspection. A professional will check the connections of electric heating elements and wires to prevent poor contact and dangerous electrical arcing.

Understanding the Key Distinction

Many homeowners confuse furnace cleaning with a different, though related, service. It's vital to know the difference to ensure you're getting the service you actually need.

Furnace Cleaning vs. Duct Cleaning

These are two separate services. Furnace cleaning is a focused, technical service on the furnace unit itself, as described above.

Duct cleaning, by contrast, focuses on the network of ductwork that runs throughout your walls and ceilings, removing dust and allergens from the air pathways. While both contribute to a healthy HVAC system, they address entirely different areas.

The DIY vs. Professional Reality

Some aspects, like wiping out the interior cabinet or cleaning the blower fan, can be done by a mechanically inclined homeowner who takes proper safety precautions, primarily disconnecting the power source.

However, components like the burners, heat exchanger, and electrical connections are best left to a trained professional. Improper cleaning can cause damage or, worse, create a safety hazard.

How to Determine Your Furnace Cleaning Needs

Use your primary goal to decide on the right course of action for your system.

- If your primary focus is routine DIY upkeep: You can safely clean the blower assembly and vacuum the interior cabinet after shutting off all power to the unit.

- If your primary focus is system efficiency and longevity: A professional cleaning that addresses the burners, heat exchanger, and combustion chamber is a wise annual investment.

- If your primary focus is safety: Professional service is the only option, as it includes essential inspections for electrical faults, combustion issues, and heat exchanger integrity.

Ultimately, understanding what furnace cleaning truly entails empowers you to maintain a safe, efficient, and reliable heating system.

Summary Table:

| Component | Purpose of Cleaning | Key Benefit |

|---|---|---|

| Blower Assembly | Remove dust from fan blades and motor | Improves airflow and energy efficiency |

| Combustion Chamber & Burners | Clear soot and debris for complete combustion | Maximizes heat output and prevents harmful byproducts |

| Heat Exchanger | Clean surfaces and inspect for cracks | Ensures safety by preventing carbon monoxide leaks |

| Furnace Interior | Vacuum out accumulated dust and particles | Protects electrical components and overall system function |

Ensure your lab's heating systems operate with maximum safety and efficiency. Just as precise furnace maintenance is critical for a safe environment, KINTEK's high-quality lab equipment and consumables are engineered for reliability and performance. From ovens and furnaces to essential lab supplies, we serve the precise needs of laboratories. Contact KINTEK today to discuss how our solutions can support your lab's operations.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs