In the context of a furnace, a retort is a sealed, heat-resistant container, often made of a nickel-based alloy, that holds the materials being heat-treated. Its primary purpose is to isolate the workload from the furnace's heating elements and the outside air. This isolation allows for the creation of a precisely controlled atmosphere inside the retort, which is critical for many advanced thermal processes.

The crucial concept to understand is that a retort transforms a furnace from a simple oven into a controlled chemical reactor. It's not just a container; it's the component that enables high-purity atmospheric control for sensitive metallurgical treatments.

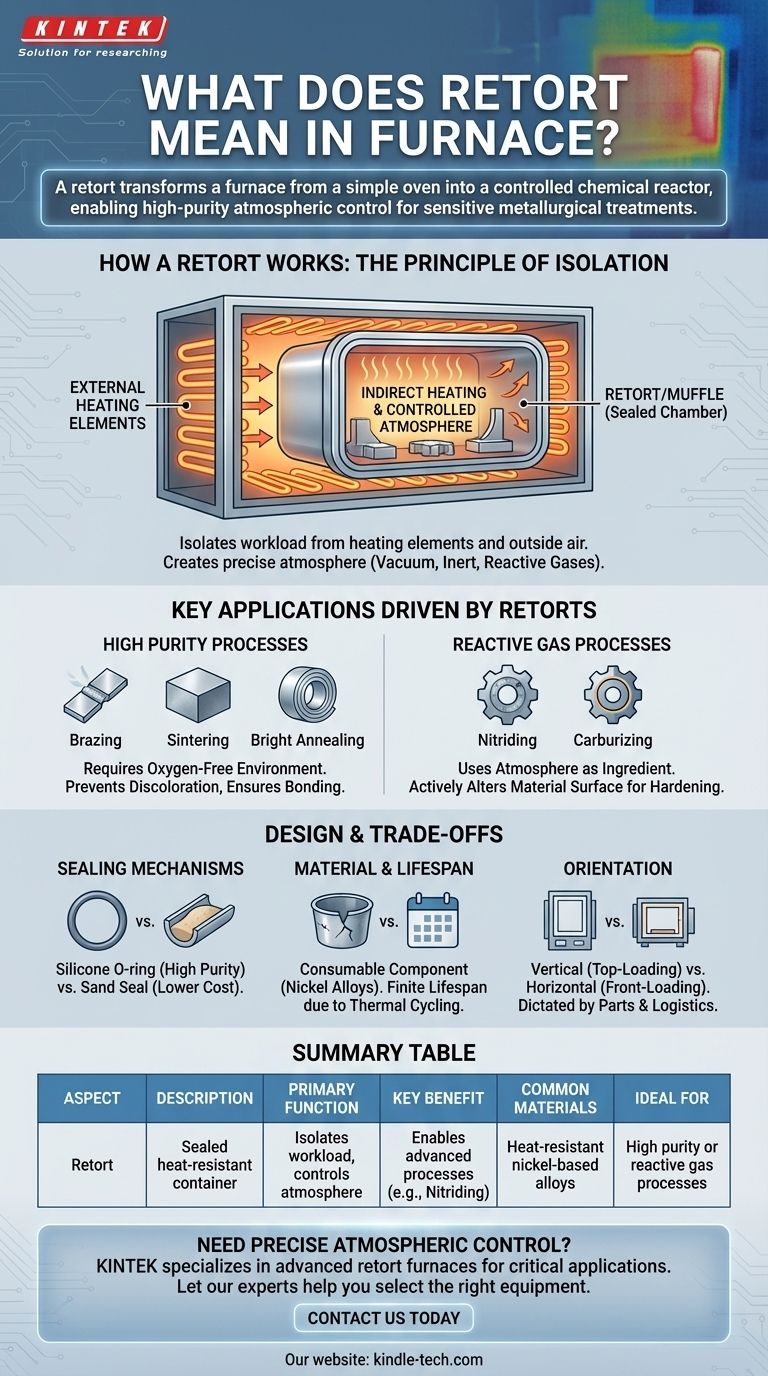

How a Retort Works: The Principle of Isolation

A retort furnace operates on a simple but effective principle: indirect heating within a controlled environment. Understanding this separation of functions is key to grasping its value.

The Retort as a Sealed Chamber

The retort itself is essentially a metallic box or pot, also known as a muffle. It is designed to withstand extreme temperatures and resist chemical reactions with the process gases.

This chamber is loaded with the parts to be treated and then sealed shut.

External Heating

The furnace's heating elements, whether electric resistance coils or gas burners, are located outside the retort.

These elements heat the retort's exterior walls. The retort then transfers this heat—primarily through radiation—to the parts located inside it. This indirect heating ensures the workload is never exposed to combustion byproducts or direct impingement from the heat source.

Creating the Controlled Atmosphere

Once sealed, the air inside the retort can be removed (creating a vacuum) or replaced with a specific gas or mixture of gases.

This is the retort's most important function. It enables processes like nitriding (using a nitrogen-rich atmosphere) or sintering (often requiring an inert atmosphere) that would be impossible in an open-air furnace due to unwanted chemical reactions like oxidation.

Key Applications Driven by Retorts

The ability to control the atmosphere unlocks a range of specialized heat-treatment processes that demand high purity and chemical precision.

Processes Requiring High Purity

Certain treatments, such as brazing, sintering, and bright annealing, require an environment completely free of oxygen to prevent discoloration and ensure proper material bonding. A sealed retort is the only way to guarantee this level of atmospheric purity.

Processes Using Reactive Gases

Other processes, like nitriding or carburizing, actively use the atmosphere as an ingredient. They introduce specific gases that react with the surface of the metal to harden it. A retort is essential to contain these reactive gases and ensure the chemical process occurs correctly and uniformly.

Understanding the Design and Trade-offs

While highly effective, retort-based systems have specific design considerations and operational trade-offs that are important to recognize.

Sealing Mechanisms

The integrity of the seal is paramount. The two most common methods are a silicone O-ring gasket clamped to the furnace exterior or a sand seal, where the retort's lip rests in a channel filled with sand.

The O-ring gasket provides a more positive seal and the highest level of atmospheric purity, while the sand seal is a simpler, lower-cost alternative for less demanding applications.

Material and Lifespan

Retorts are made from expensive, high-temperature nickel alloys. However, they are fundamentally consumable components.

The constant thermal cycling of heating and cooling causes stress and eventual degradation. A retort's lifespan is finite, and it must be periodically replaced, representing a significant operational cost.

Horizontal vs. Vertical Orientation

Retort furnaces can be designed as either top-loading vertical chambers or front-loading horizontal ones. This choice is not a matter of performance but is dictated by the type of parts being processed and the material handling logistics of the facility.

Making the Right Choice for Your Process

Selecting a retort furnace is a decision based entirely on the chemical and atmospheric requirements of your thermal process.

- If your primary focus is maximum atmospheric purity for a flawless surface finish: A retort furnace with a high-quality gasket seal is the definitive choice.

- If your process requires introducing a specific reactive gas to alter the material's surface: The retort is non-negotiable to contain the atmosphere and ensure process consistency.

- If you are performing simple treatments like stress-relieving or tempering that do not require a special atmosphere: A retort furnace is likely an unnecessary expense, and a direct-fired or standard atmospheric furnace would be more cost-effective.

Ultimately, a retort is the critical component that transforms a simple heating chamber into a precise metallurgical tool.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Isolates workload to create a precisely controlled atmosphere (e.g., inert, reactive). |

| Key Benefit | Enables advanced processes like nitriding, sintering, and bright annealing by preventing oxidation. |

| Common Materials | Heat-resistant nickel-based alloys. |

| Ideal For | Processes requiring high atmospheric purity or the use of reactive gases. |

Need precise atmospheric control for your heat-treating process?

At KINTEK, we specialize in advanced furnace solutions for laboratories. Our retort furnaces are engineered to deliver the high-purity environments required for critical applications like brazing, sintering, and nitriding, ensuring flawless results and material integrity.

Let our experts help you select the right equipment for your specific metallurgical needs. Contact us today to discuss your application and discover the KINTEK advantage.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes