At its core, professional sieving requires a sieve shaker, a calibrated set of test sieves, and a collection pan. This system moves far beyond simple screening, creating a controlled environment for precise and repeatable particle size analysis. The quality and calibration of these components directly determine the accuracy of your results.

The essential insight is that sieving for analytical purposes is not just about separation. It's about establishing a repeatable, standardized process where the equipment—from the shaker to the sieves themselves—works as a single system to produce reliable data.

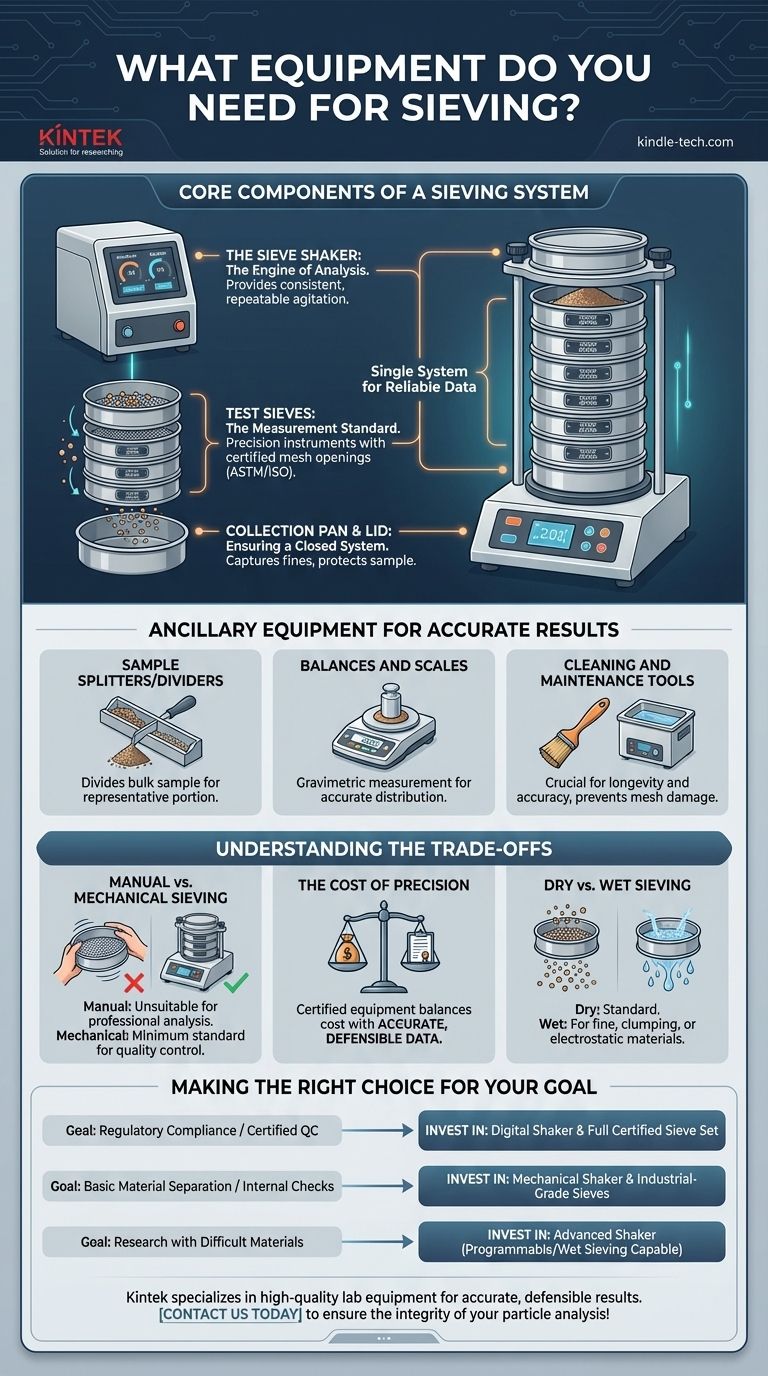

The Core Components of a Sieving System

To achieve accurate particle size analysis, three primary pieces of equipment are non-negotiable. They form the foundation of the entire process.

The Sieve Shaker: The Engine of Analysis

A sieve shaker is the motorized unit that provides the agitation needed to separate particles. Its primary purpose is to ensure the separation is consistent and repeatable every single time.

Modern, high-end shakers feature digital controls for parameters like vibration amplitude and duration. This removes the human variability inherent in manual shaking and is essential for any laboratory environment where results must be defensible.

Test Sieves: The Measurement Standard

Test sieves are the most critical component. These are not just simple screens; they are precision instruments with a woven wire mesh or perforated plate held in a rigid frame.

Each sieve is manufactured to meet strict standards (like ASTM or ISO) that certify the opening size of the mesh. For a proper analysis, you will use a "stack" of sieves with progressively smaller mesh openings, arranged from largest on top to smallest on the bottom.

Collection Pan and Lid: Ensuring a Closed System

A solid collection pan is placed at the very bottom of the sieve stack. Its job is to collect the finest particles that pass through all the sieves, often referred to as "fines" or the "pan fraction."

A lid is placed on top of the entire stack. This prevents any loss of sample material during the vigorous shaking process and protects the sample from airborne contaminants.

Ancillary Equipment for Accurate Results

Beyond the core components, several other tools are required to follow a correct analytical procedure from start to finish.

Sample Splitters/Dividers

For large initial samples, a sample splitter (or riffler) is used. This device divides the bulk sample into a smaller, but still statistically representative, portion for analysis. This ensures the small amount you test accurately reflects the entire batch.

Balances and Scales: The Basis of Measurement

Sieve analysis is a gravimetric method, meaning it relies on weight. A precision balance is mandatory for weighing the initial sample and then weighing the material retained on each individual sieve after shaking. The accuracy of your balance directly impacts the accuracy of your final particle size distribution report.

Cleaning and Maintenance Tools

Properly caring for your test sieves is crucial for their longevity and accuracy. This requires dedicated sieve brushes with bristles that won't damage the delicate mesh. For thorough cleaning, an ultrasonic bath is often used to dislodge fine particles without harming the sieve.

Understanding the Trade-offs

Investing in proper sieving equipment requires balancing cost against the need for accuracy.

Manual vs. Mechanical Sieving

While manual sieving is possible, it is entirely unsuitable for professional analysis. The results are impossible to replicate because the agitation (tapping, shaking, rotating) cannot be controlled. A mechanical sieve shaker is the minimum standard for any quality control or research application.

The Cost of Precision

Certified test sieves and digital shakers represent a significant investment. This cost is justified by the need for accurate, defensible data. Using uncertified or damaged equipment can lead to incorrect conclusions, failed quality audits, or flawed research.

Dry vs. Wet Sieving

For materials that are very fine, clump together, or have electrostatic charges, dry sieving may not be effective. Wet sieving attachments are available for many shakers, which introduce a liquid (usually water) to help wash the particles through the sieves for a more accurate separation.

Making the Right Choice for Your Goal

Your specific application will determine the level of equipment you need.

- If your primary focus is regulatory compliance or certified quality control: You must invest in a digital sieve shaker and a full set of certified, traceable test sieves to ensure your results are repeatable and defensible.

- If your primary focus is basic material separation for internal process checks: A basic mechanical shaker and a limited set of industrial-grade sieves may suffice, but the data should not be used for external reporting.

- If your primary focus is research with difficult materials: You should prioritize a shaker with advanced features, such as programmable agitation patterns or wet sieving capabilities, to handle unique particle characteristics.

Ultimately, selecting the right sieving equipment is about investing in the confidence and integrity of your results.

Summary Table:

| Core Component | Key Function | Critical Feature |

|---|---|---|

| Sieve Shaker | Provides consistent, repeatable agitation | Digital controls for amplitude & duration |

| Test Sieves | Precision measurement of particle size | Certified to ASTM/ISO standards |

| Collection Pan & Lid | Captures fines and protects sample | Ensures a closed, contamination-free system |

Ready to build a sieving system that delivers accurate, defensible results? KINTEK specializes in high-quality lab equipment and consumables, including precision sieve shakers and certified test sieves tailored to your laboratory's needs. Our experts can help you select the right components for compliance, quality control, or advanced research. Contact us today to ensure the integrity of your particle analysis!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the different methods of sieving? Choose the Right Technique for Your Material

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What size are test sieves? A Guide to Frame Diameters and Mesh Sizes

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis