In short, hammer mills are used across nearly every major processing industry. Their versatility makes them a foundational piece of equipment in sectors ranging from agriculture and food production to biomass, recycling, and mineral processing. The core function of a hammer mill—brute-force particle size reduction—is a fundamental need in countless industrial value chains.

A hammer mill's widespread adoption stems from its simple, robust design. It excels at providing reliable and cost-effective grinding for a vast spectrum of brittle and fibrous materials, making it one of the most versatile size-reduction tools available.

The Core Principle: Why Hammer Mills Are So Common

To understand the "why" behind their use, you must first understand the "how." A hammer mill is a fundamentally simple machine that reduces the size of material through repeated impact.

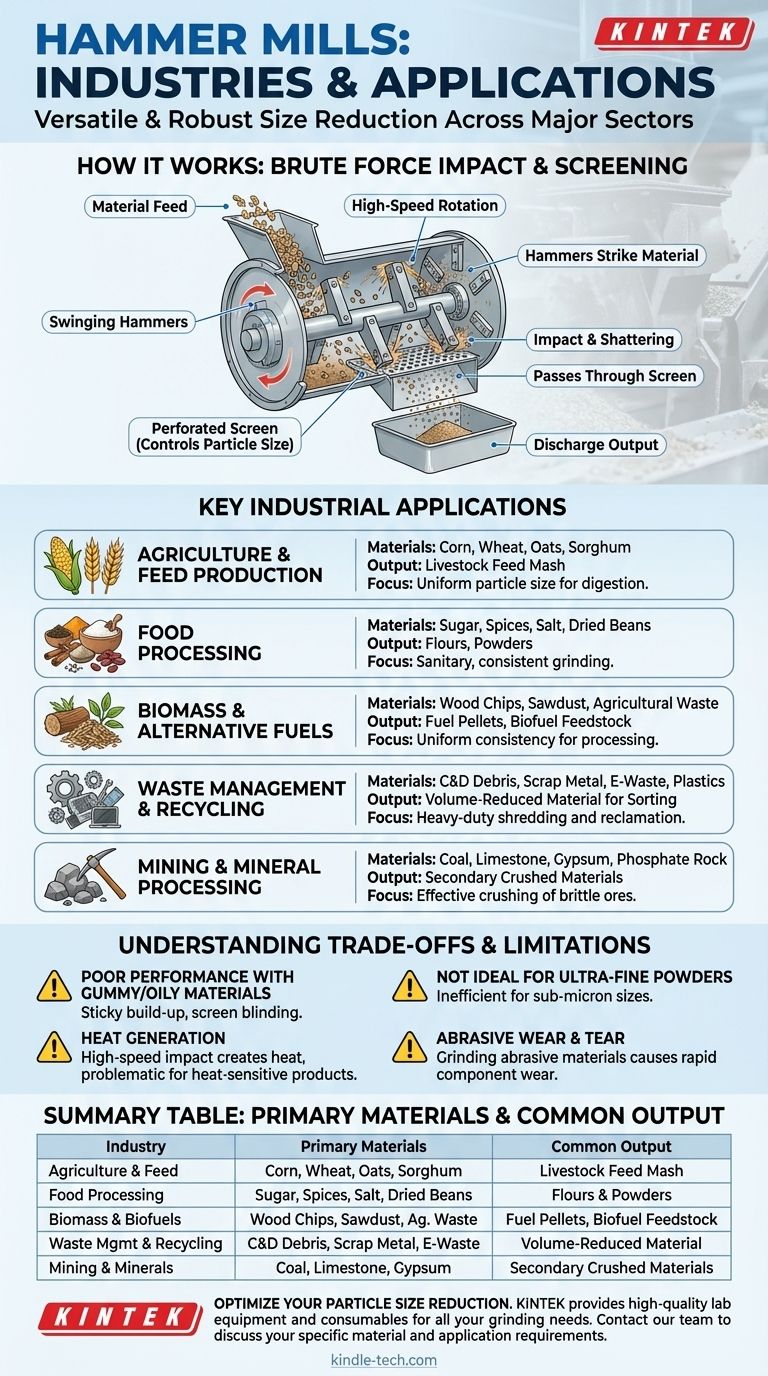

How It Works: Brute Force Impact

Material is fed into a grinding chamber containing a rotating shaft. A series of swinging hammers are attached to this shaft.

As the shaft spins at high speed, these hammers strike the material, shattering it against the chamber walls and breaker plates. This process continues until the particles are small enough to pass through a perforated screen that covers the discharge opening.

The Key to Versatility: The Screen

The final particle size is determined almost entirely by the size of the holes in the discharge screen.

By simply swapping out this screen, an operator can change the finished particle size from a coarse crack (for animal feed) to a fine powder (for flour or chemicals) using the same machine. This adaptability is a primary driver of its broad industrial use.

A Breakdown of Key Industrial Applications

The hammer mill's simple principle of impact grinding is applied to dozens of materials for different commercial purposes.

Agriculture and Feed Production

This is the most traditional and highest-volume application. Hammer mills are used to grind grains like corn, wheat, oats, and sorghum into mash for livestock and poultry feed. The ability to control particle size is critical for animal digestion and nutrient absorption.

Food Processing

For human consumption, hammer mills grind everything from sugar and spices to salt and dried beans. In these applications, they are typically constructed from stainless steel to meet strict sanitation and food safety standards. They are also used to create flours from various grains and pulses.

Biomass and Alternative Fuels

The renewables sector relies heavily on hammer mills to process wood chips, sawdust, agricultural waste (like corn stover), and switchgrass. Grinding this fibrous biomass into a uniform consistency is a crucial first step for creating fuel pellets or preparing feedstock for ethanol production.

Waste Management and Recycling

Heavy-duty hammer mills, often called "shredders" in this context, are workhorses in the recycling industry. They are used to pulverize construction and demolition (C&D) debris, scrap metal, e-waste, and even plastics to reduce volume and prepare the material for sorting and reclamation.

Mining and Mineral Processing

In the mineral industry, hammer mills are used for the secondary crushing of brittle materials. They effectively grind coal, limestone, gypsum, clay, and phosphate rock after a primary jaw or gyratory crusher has done the initial work.

Understanding the Trade-offs

Despite their versatility, hammer mills are not the right tool for every job. Understanding their limitations is key to proper application.

Limitation 1: Poor Performance with Gummy or Oily Materials

Materials with high moisture or oil content, such as certain spices or oily seeds, can become sticky when ground. This can cause the material to build up inside the mill and "blind" the screen, stopping the flow of product and requiring a shutdown for cleaning.

Limitation 2: Heat Generation

The high-speed impact action generates significant heat. This can be a major problem for heat-sensitive materials like low-melt-point plastics, certain chemicals, or spices where excess heat can destroy volatile oils and compromise flavor.

Limitation 3: Not Ideal for Ultra-Fine Powders

While a hammer mill can produce a fine powder, it is not efficient for creating ultra-fine or sub-micron particles. For applications requiring extremely small particle sizes, technologies like jet mills or media mills are superior.

Limitation 4: Abrasive Wear and Tear

Grinding highly abrasive materials like glass, quartz, or fired ceramics will cause rapid wear on the hammers and screens. While mills can be outfitted with hardened components, frequent maintenance and replacement of wear parts is an expected operational cost in these applications.

Making the Right Choice for Your Material

Your choice of grinding equipment must be driven by the properties of your input material and your desired output.

- If your primary focus is cost-effective, high-volume grinding of brittle or fibrous materials: The hammer mill is an excellent and often default choice for applications like animal feed, biomass, or basic mineral crushing.

- If your primary focus is grinding soft, sticky, or heat-sensitive products: You must explore alternative technologies like a cutter mill (for soft plastics) or cryogenic grinding (using liquid nitrogen to make the material brittle).

- If your primary focus is achieving an extremely fine, consistent particle size for high-spec applications: A hammer mill may be a preliminary step, but a ball mill, jet mill, or other fine-grinding mill will be required to reach the final specification.

Ultimately, understanding the simple principle of impact grinding is the key to knowing when a hammer mill is the right tool for your specific size reduction challenge.

Summary Table:

| Industry | Primary Materials Processed | Common Output |

|---|---|---|

| Agriculture & Feed Production | Corn, wheat, oats, sorghum | Livestock feed mash |

| Food Processing | Sugar, spices, salt, dried beans | Flours and powders |

| Biomass & Alternative Fuels | Wood chips, sawdust, agricultural waste | Fuel pellets, biofuel feedstock |

| Waste Management & Recycling | C&D debris, scrap metal, e-waste, plastics | Volume-reduced material for sorting |

| Mining & Mineral Processing | Coal, limestone, gypsum, phosphate rock | Secondary crushed materials |

Ready to Optimize Your Particle Size Reduction Process?

KINTEK specializes in providing high-quality lab equipment and consumables for all your grinding and processing needs. Whether you're in agriculture, recycling, or any other industry requiring reliable size reduction, our hammer mills and expert support can help you achieve consistent, cost-effective results.

Contact our team today to discuss your specific material and application requirements. Let KINTEK be your trusted partner in laboratory efficiency and productivity.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What role does a mechanical ball mill play in Al-Sn/Graphene production? Master Nano-Dispersion and Alloying

- What function does an Agate Mortar and Pestle serve in Na3OBr synthesis? Achieve Pure Solid-State Electrolytes

- Why is an agate mortar necessary for pre-treating carbonate rock samples? Ensure Purity in CO2-Water-Rock Experiments

- What is the ball milling process used for? A Guide to Grinding, Alloying, and Blending Materials

- What size are the balls in a ball mill? Optimize Your Grinding Process for Peak Efficiency

- What is the function of a ball mill in Reaction Bonded Boron Carbide? Achieve Optimal Powder Homogeneity for RBBC

- What does a grinder do in a laboratory? Achieve Homogeneous Sample Preparation for Accurate Analysis

- Why are zirconia grinding jars and balls required for solid-state electrolyte powders? Ensure High Purity & Performance