At its core, a 3-high rolling mill is a machine used for shaping metal that features three rolls stacked vertically. Unlike simpler 2-high mills, this configuration allows the workpiece to be passed back and forth through the mill without needing to reverse the direction of the powerful driving motor, making it a historically significant and efficient design for intermediate metal reduction.

The defining characteristic of a 3-high mill is not just its three rolls, but its operational efficiency. It enables bidirectional rolling, allowing for multiple reduction passes on a single piece of metal in a compact, mechanically simpler setup than modern reversing mills.

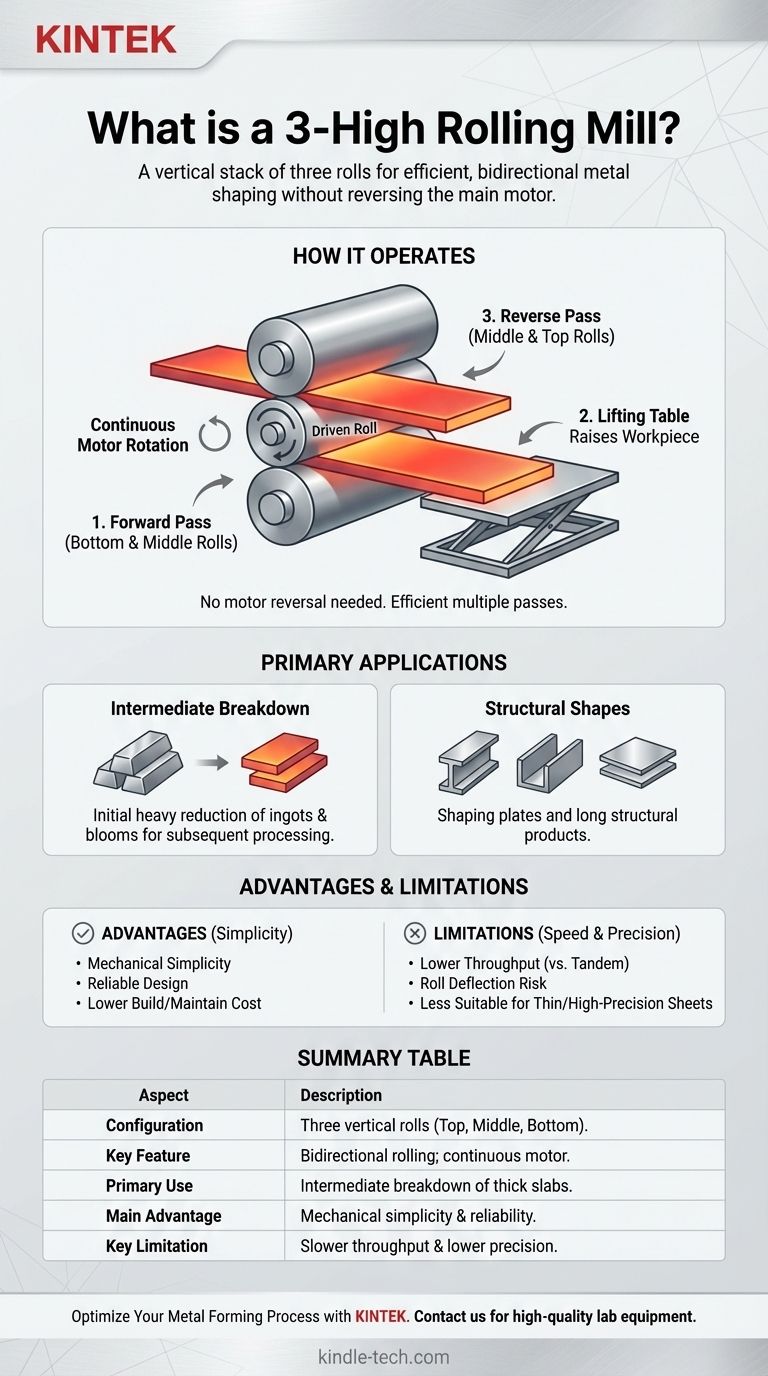

How a 3-High Rolling Mill Operates

To understand the value of a 3-high mill, you must first understand its unique mechanical process. It is a clever solution to the problem of performing multiple rolling passes efficiently.

The Vertical Roll Configuration

A 3-high mill consists of a top roll, a middle roll, and a bottom roll arranged in a vertical stack. The middle roll is typically driven directly by the motor, while the top and bottom rolls are often driven by friction from their contact with the workpiece and the middle roll.

The Bidirectional Rolling Process

The key to its operation is the path of the metal. First, the workpiece (like a hot steel slab) is passed between the bottom and middle rolls.

After it exits, a lifting table raises the workpiece so it is aligned with the gap between the middle and top rolls. The metal is then passed back through in the opposite direction. This cycle can be repeated multiple times.

The Advantage of Continuous Rotation

This design was ingenious for its time. The main motor and rolls can spin continuously in one direction. The reversal of the metal's travel is handled by simply redirecting it through a different roll gap, avoiding the need for a complex and expensive reversing motor.

Primary Purpose and Applications

While modern mills have surpassed them in certain areas, 3-high mills remain relevant for specific stages of metal forming, particularly for roughing and intermediate work.

Intermediate Breakdown Work

Their most common application is as roughing or breakdown mills. They take thick initial forms of metal, such as ingots or blooms, and perform the initial heavy reductions in thickness.

The goal here is not final precision but efficient, substantial size reduction, preparing the metal for subsequent finishing passes in other types of mills.

Producing Plates and Structural Shapes

3-high mills are also frequently used to produce plates and long structural products like beams and channels. The bidirectional process is well-suited for shaping these larger, less-precise items.

Understanding the Trade-offs

No single mill design is perfect for every task. The 3-high mill's advantages in simplicity come with limitations in speed and precision compared to more specialized equipment.

Advantage: Mechanical Simplicity

The primary benefit is its robust and relatively simple design. By avoiding a reversing motor, the mill is mechanically less complex and historically was more reliable and less costly to build and maintain.

Disadvantage: Lower Throughput

The process of rolling, lifting the table, and passing the material back is slower than a tandem mill, where metal passes through a series of 2-high or 4-high stands in a single, continuous line.

Limitation: Roll Deflection and Precision

Because the work rolls are not supported by larger "backup rolls" (a feature of 4-high mills), they can be more prone to bending or deflection under heavy load. This makes 3-high mills less suitable for producing very thin or high-precision flat-rolled products, where maintaining a perfectly uniform thickness is critical.

Making the Right Choice for Your Goal

Selecting the correct rolling mill technology depends entirely on the stage of production and the desired characteristics of the final product.

- If your primary focus is intermediate reduction of thick slabs: A 3-high mill is a classic and effective choice for this "roughing" stage, offering good efficiency for heavy work.

- If your primary focus is high-volume, continuous production of a single product: A tandem mill setup is far more productive, as it eliminates the time lost reversing the material.

- If your primary focus is producing finished, high-precision flat sheets: A 4-high or advanced cluster mill is superior, as their backup rolls minimize deflection and ensure exceptional flatness and gauge control.

Ultimately, the 3-high mill represents a pivotal design in metalworking, optimized for the specific task of efficient, bidirectional intermediate shaping.

Summary Table:

| Aspect | Description |

|---|---|

| Roll Configuration | Three rolls stacked vertically (top, middle, bottom). |

| Key Feature | Bidirectional rolling; material passes back and forth without reversing the motor. |

| Primary Use | Intermediate breakdown/roughing of thick slabs, ingots, and blooms. |

| Main Advantage | Mechanical simplicity and reliability for heavy reduction. |

| Key Limitation | Slower throughput than tandem mills; less precision for thin sheets due to roll deflection. |

Optimize Your Metal Forming Process with KINTEK

Are you involved in intermediate metal reduction or roughing operations? The principles of efficient, robust machinery—exemplified by the 3-high mill—are at the core of what we do. KINTEK specializes in providing high-quality lab equipment and consumables tailored to the demanding needs of metallurgical laboratories and R&D facilities.

We understand that precision and reliability are critical. Whether you are testing material properties, developing new alloys, or simulating industrial processes, our equipment is designed to deliver accurate and consistent results.

Let us help you achieve your goals.

Contact us today to discuss how our solutions can enhance your laboratory's efficiency and support your metalworking research and development.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

People Also Ask

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- What is the difference between monolayer and multilayer film? Choose the Right Packaging for Your Product

- What is the milling process of rubber? Transform Raw Rubber into a Workable Compound

- What is cheaper than injection molding? Discover Cost-Effective Alternatives for Low-Volume Production

- What is the pyrolysis of natural rubber? A Sustainable Solution for Tire and Rubber Waste

- What is the process of multilayer co extrusion? Engineer High-Performance Composite Materials

- What is a two roll mill? Master Polymer Mixing for R&D and Quality Control