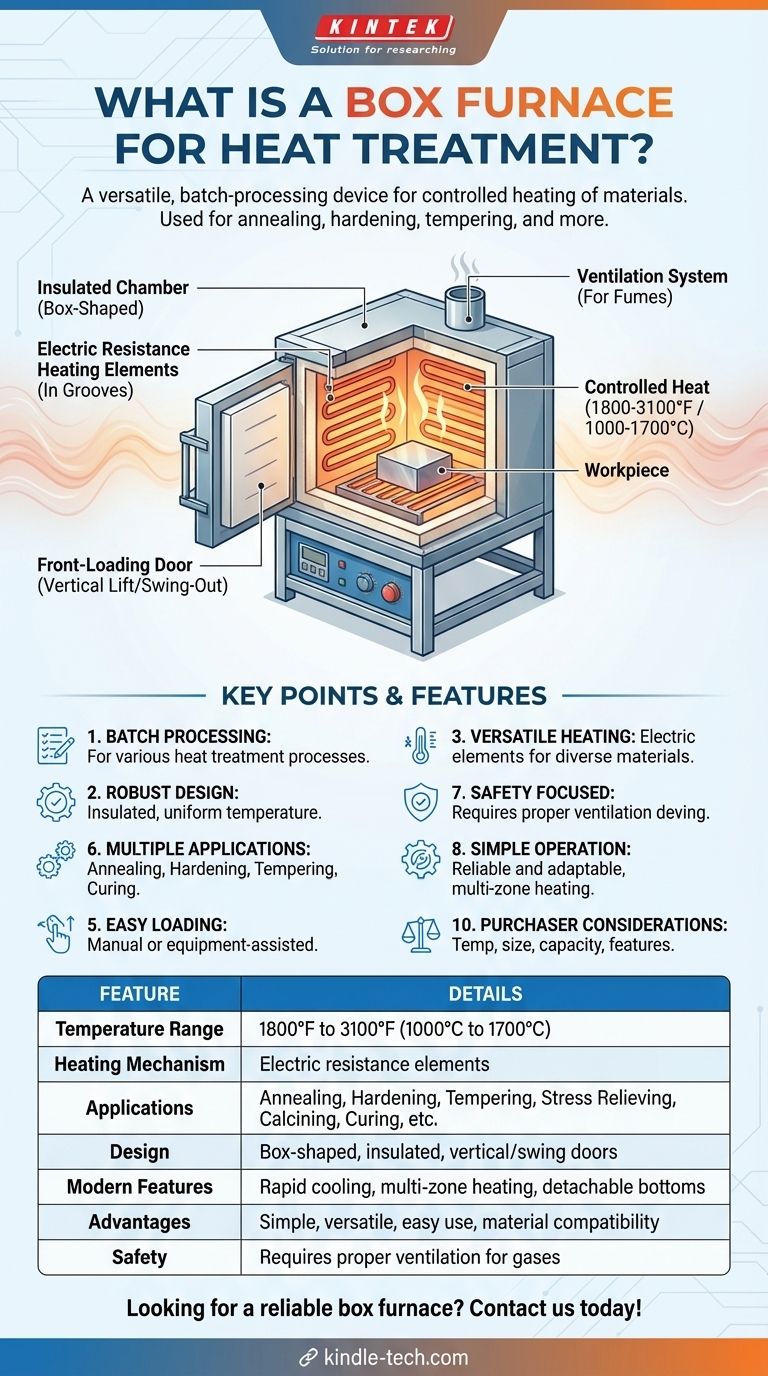

A box furnace for heat treatment is a versatile and widely used industrial heating device designed for batch processing of materials. It features a box-shaped insulated chamber that accommodates workpieces for controlled heating at specific temperatures. These furnaces are commonly used for processes like annealing, hardening, tempering, stress relieving, and other high-temperature treatments. They are available in various sizes, from small tabletop models to large heavy-duty units, and can operate at temperatures ranging from 1800°F to 3100°F (1000°C to 1700°C). Box furnaces are known for their simple design, ease of use, and ability to handle a wide range of materials and applications. They are typically heated by electric resistance elements and may include features like vertical lift or swing-out doors for easy loading and unloading. Proper ventilation or exhaust systems are required to manage volatile gases released during heating.

Key Points Explained:

-

Definition and Purpose of a Box Furnace:

- A box furnace is a batch-operating furnace designed for heat treatment processes.

- It is used for annealing, hardening, tempering, stress relieving, calcining, curing, and preheating.

- The furnace provides controlled heating at specific temperatures to achieve desired material properties.

-

Design and Structure:

- The furnace has a rectangular, box-shaped chamber with an insulated interior to maintain uniform temperature distribution.

- It features a front-loading mechanism with single or multiple doors that can swing out or lift vertically for easy access.

- Modern designs may include a detachable, movable bottom (elevator-type) for handling large and heavy loads.

-

Heating Mechanism:

- Box furnaces are typically heated by electric resistance elements, often placed in refractory grooves.

- The heating elements generate the required heat, and insulation ensures consistent temperature throughout the chamber.

-

Temperature Range and Versatility:

- Box furnaces can operate at temperatures ranging from 1800°F to 3100°F (1000°C to 1700°C).

- They are versatile and can handle a variety of materials, including low alloy steels, ceramics, and composites.

-

Loading and Unloading:

- Workpieces are loaded manually or using equipment like forklifts or cranes for heavy components.

- The design allows for easy placement of products in a range of sizes, making it suitable for small to medium-sized parts.

-

Applications:

- Commonly used in industries for heat-treating, calcining, curing, annealing, stress relieving, preheating, and tempering.

- Suitable for both small-scale and large-scale operations, depending on the furnace size and configuration.

-

Safety and Ventilation:

- Volatile materials in samples burn off during heating, releasing gases that require proper ventilation.

- Furnaces must be placed in fume hoods or equipped with local exhaust systems like canopy or snorkel hoods to manage fumes.

-

Advantages:

- Simple and problem-free design, making them easy to operate and maintain.

- Versatile and adaptable to various heat treatment processes and material types.

- Available in a range of sizes and configurations, from tabletop models to heavy-duty multi-level units.

-

Modern Features:

- Some box furnaces include rapid cooling systems using high-velocity gas systems for faster processing.

- Multi-zone heating capabilities allow for precise temperature control across different sections of the furnace.

-

Considerations for Purchasers:

- Evaluate the required temperature range, chamber size, and load capacity based on specific application needs.

- Ensure the furnace design aligns with the type of materials and processes being used.

- Consider additional features like ventilation systems, rapid cooling, and multi-zone heating for enhanced functionality.

Summary Table:

| Feature | Details |

|---|---|

| Temperature Range | 1800°F to 3100°F (1000°C to 1700°C) |

| Heating Mechanism | Electric resistance elements |

| Applications | Annealing, hardening, tempering, stress relieving, calcining, curing, etc. |

| Design | Box-shaped insulated chamber with vertical lift or swing-out doors |

| Modern Features | Rapid cooling systems, multi-zone heating, detachable bottoms |

| Advantages | Simple design, versatility, ease of use, and wide material compatibility |

| Safety Considerations | Requires proper ventilation or exhaust systems for volatile gases |

Looking for a reliable box furnace for your heat treatment needs? Contact us today to find the perfect solution!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation