At its core, a controlled atmosphere processing system is an engineered environment where the atmospheric composition, pressure, and temperature are precisely managed to achieve a specific outcome. These systems are essential in fields ranging from semiconductor manufacturing and materials science to food processing. They work by replacing ambient air with a carefully regulated mixture of gases, creating conditions that enable processes that would otherwise be impossible.

The fundamental principle is not about a single machine, but about the precise management of a gaseous environment. By removing reactive elements like oxygen and introducing specific process gases, these systems allow for unparalleled control over chemical and physical transformations.

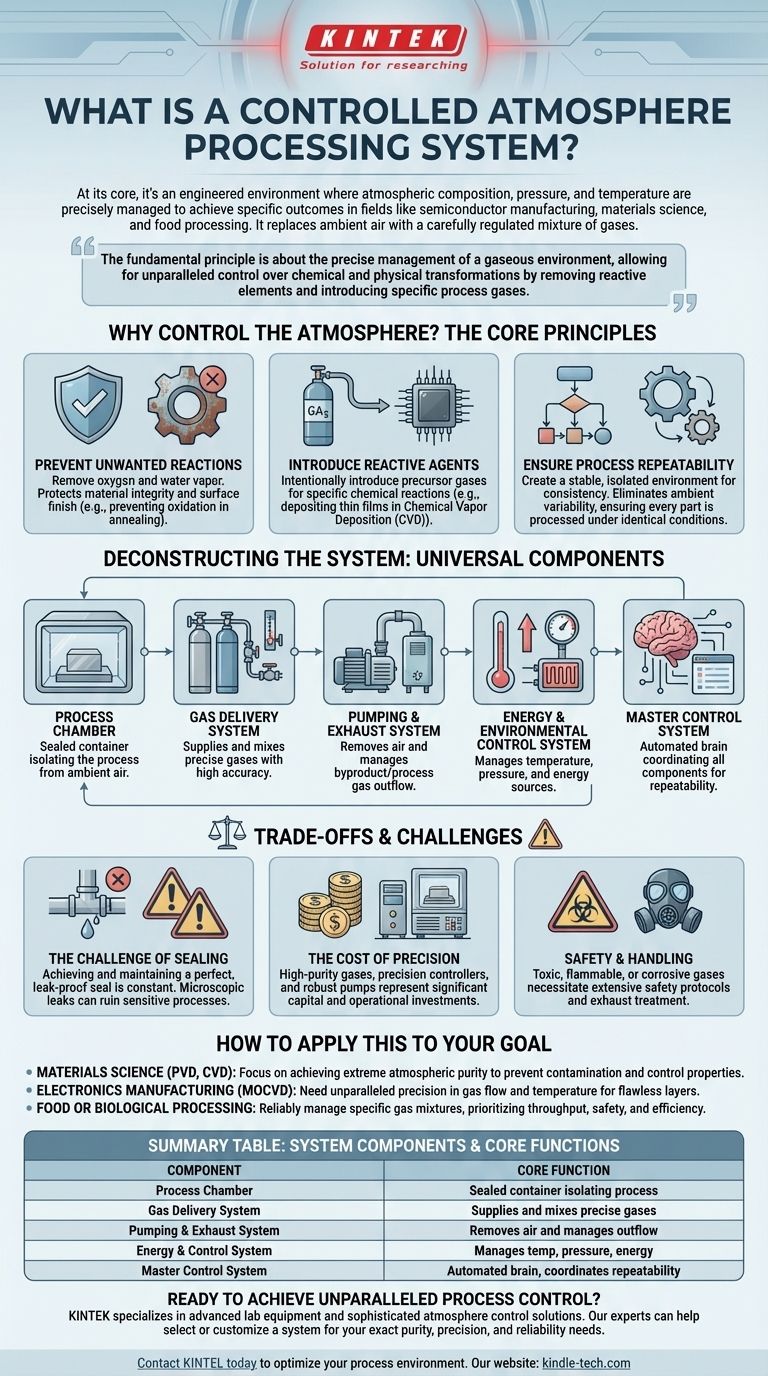

The Core Principle: Why Control the Atmosphere?

Normal air is a complex mixture of gases—primarily nitrogen and oxygen, with traces of water vapor, argon, and carbon dioxide. For many advanced processes, these components are contaminants that interfere with the desired outcome.

To Prevent Unwanted Reactions

The most common reason to control an atmosphere is to remove oxygen and water vapor. During high-temperature processes like metal heat treatment (annealing), oxygen will cause oxidation, or rust, which degrades the material's quality.

By replacing air with an inert gas like nitrogen or argon, the material is protected from these unwanted chemical reactions, ensuring its integrity and surface finish.

To Introduce Reactive Agents

Conversely, some processes require specific reactive gases that aren't present in normal air. In Chemical Vapor Deposition (CVD), precursor gases are intentionally introduced into a chamber.

These gases react on a heated surface to deposit a thin, solid film—a fundamental technique for creating computer chips and protective coatings. The controlled atmosphere ensures only the desired reactions occur.

To Ensure Process Repeatability

By creating a stable, well-defined, and isolated environment, these systems eliminate the variability of ambient conditions. This ensures that every part or batch is processed under the exact same conditions. This repeatability is critical for high-volume manufacturing where consistency is paramount.

Deconstructing the System: Universal Components

While a system for stunning poultry is very different from one for growing a semiconductor crystal, they share a common architectural DNA. The references to MOCVD, PVD, and CVD systems reveal a set of five core functional blocks.

The Process Chamber

This is the heart of the system—a sealed container where the work happens. It can be a steel vacuum chamber for PVD, a quartz tube furnace for CVD, or a larger enclosure for food processing. Its primary job is to isolate the process from the outside world.

The Gas Delivery System

This subsystem is responsible for supplying, mixing, and delivering the precise gases required. It uses high-purity gas sources and sophisticated mass flow controllers to regulate the flow of each gas with extreme accuracy, ensuring the atmospheric recipe is perfect.

The Pumping & Exhaust System

This system serves two purposes. First, a vacuum pump removes the ambient air to create a clean slate. Second, it manages the outflow of process gases and byproducts. This may involve a "scrubber" to neutralize hazardous exhaust before it is released.

The Energy & Environmental Control System

This includes all the hardware used to manage the physical environment inside the chamber. It consists of heaters or coolers to control temperature, as well as pressure sensors and valves. In a furnace, this is the heating element; in a deposition system, it's often a complex energy source like a plasma generator.

The Master Control System

This is the brain of the operation. Modern systems are managed by sophisticated electronics and software that automate the entire process. The control system monitors all sensors and precisely coordinates the gas delivery, pumping, and energy systems to execute the programmed recipe.

Understanding the Trade-offs and Challenges

Controlled atmosphere systems provide immense capability, but this comes with significant engineering challenges and operational costs.

The Challenge of Sealing

Achieving and maintaining a perfect, leak-proof seal on the process chamber is a constant battle. Even microscopic leaks can introduce contaminants like oxygen or moisture, ruining sensitive processes. This is often the primary source of process failure and requires diligent maintenance.

The Cost of Precision

The components required for precise control are expensive. High-purity gases, precision mass flow controllers, and robust vacuum pumps represent a significant capital investment. The operational cost of gases and energy can also be substantial.

Safety and Handling

Many of the gases used in materials science and electronics manufacturing are toxic, flammable, or corrosive. This necessitates extensive safety protocols, specialized gas cabinets, leak detectors, and exhaust treatment systems to protect personnel and the environment.

How to Apply This to Your Goal

Understanding the core principles allows you to identify the most critical aspects of a system based on your specific application.

- If your primary focus is materials science (e.g., heat treatment, PVD, CVD): Your main concern is achieving extreme atmospheric purity to prevent contamination and precisely control material properties.

- If your primary focus is electronics manufacturing (e.g., MOCVD): You need unparalleled precision and repeatability in gas flow and temperature to deposit atomically thin, flawless layers.

- If your primary focus is food or biological processing (e.g., stunning, packaging): Your goal is to reliably manage a specific gas mixture to control a biological process, prioritizing throughput, safety, and efficiency over extreme vacuum or purity.

By grasping these fundamental building blocks, you can effectively evaluate, operate, and troubleshoot any controlled atmosphere system you encounter.

Summary Table:

| System Component | Core Function |

|---|---|

| Process Chamber | Sealed container isolating the process from ambient air. |

| Gas Delivery System | Supplies and mixes precise gases with high accuracy. |

| Pumping & Exhaust System | Removes air and manages byproduct/process gas outflow. |

| Energy & Control System | Manages temperature, pressure, and energy sources. |

| Master Control System | Automated brain coordinating all components for repeatability. |

Ready to achieve unparalleled process control and repeatability?

Whether your work is in sensitive materials science, high-precision electronics manufacturing, or large-scale industrial processing, the right controlled atmosphere system is critical to your success. KINTEK specializes in advanced lab equipment, including sophisticated atmosphere control solutions.

Our experts can help you select or customize a system that delivers the exact purity, precision, and reliability your application demands. Let's discuss your specific goals and challenges.

Contact KINTEL today to optimize your process environment.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is hydrogen used in annealing furnaces? Achieve Superior Surface Quality & Faster Cycles

- Why is a 1937 K high-temperature atmosphere furnace required for iron-free magnesium spinels? Achieve Phase Purity

- What is the role of a high-temperature atmosphere furnace in the growth of alpha-Al2O3 and alpha-Fe2O3 oxide films?

- What is the atmosphere of a heat treatment furnace? Mastering Surface Chemistry for Superior Materials

- What process environment does an atmosphere sintering furnace provide for LLZ-LGVO? Achieve High-Purity Densified Bonding

- How does a high-temperature atmosphere sintering furnace contribute to UO2 fuel pellets? Achieve High-Density Precision

- What are the common applications of a dry hydrogen atmosphere? Enhance Precision in Metallurgy & Advanced Brazing

- How do atmosphere or vacuum furnaces protect sulfide electrolytes? Key Insights for Safe & High-Performance Synthesis