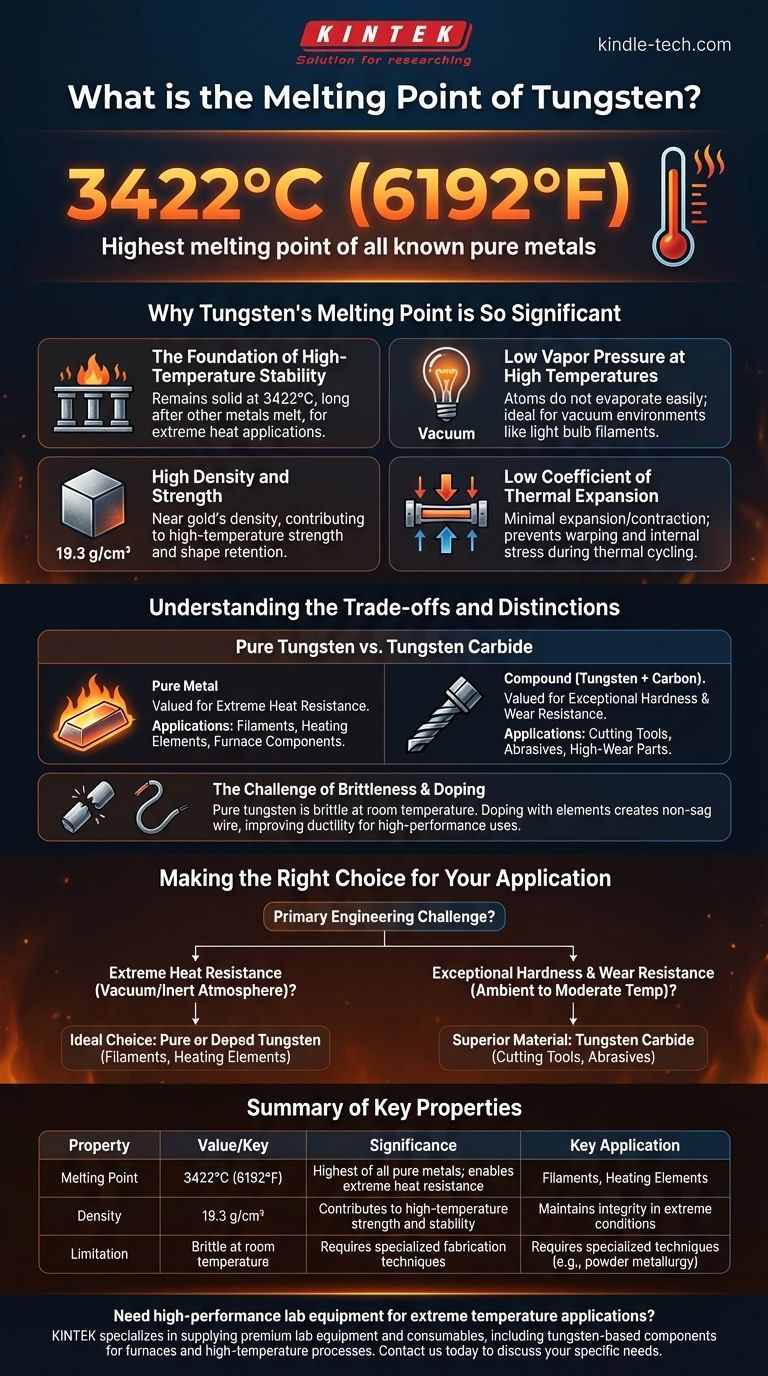

The melting point of tungsten is 3422°C (6192°F). This is the highest melting point of all known pure metals, a fundamental property that defines its primary use in extreme temperature applications. It is this characteristic, combined with its other physical properties, that makes tungsten a critical material in advanced engineering and technology.

While its record-high melting point is tungsten's most famous attribute, its true value emerges from the combination of this heat resistance with high density, low thermal expansion, and low vapor pressure, making it uniquely stable under extreme conditions.

Why Tungsten's Melting Point is So Significant

A high melting point is more than just a number; it is the cornerstone of a material's performance in demanding environments. For tungsten, this property is the gateway to a host of other high-performance characteristics.

The Foundation of High-Temperature Stability

The ability to remain solid at 3422°C means tungsten maintains its structural integrity long after steel, titanium, and other refractory metals have melted. This makes it an essential component for applications that operate in extreme heat.

Low Vapor Pressure at High Temperatures

Crucially, a high melting point is correlated with a low vapor pressure. This means that even at very high temperatures, tungsten atoms do not readily evaporate into a gas. This is why it was the material of choice for incandescent light bulb filaments, which operate in a vacuum.

High Density and Strength

Tungsten is incredibly dense, at 19.3 g/cm³, nearly the same as gold. This mass contributes to its high-temperature strength, allowing it to resist deformation and maintain its shape even when heated.

Low Coefficient of Thermal Expansion

Tungsten expands and contracts very little when its temperature changes. This thermal stability is critical for components that undergo rapid heating and cooling cycles, as it prevents internal stress, warping, and eventual failure.

Understanding the Trade-offs and Distinctions

While its heat resistance is unparalleled, tungsten is not a universal solution. Understanding its limitations and how it differs from its famous derivative, tungsten carbide, is key to using it effectively.

Pure Tungsten vs. Tungsten Carbide

Many people confuse tungsten with tungsten carbide. They are fundamentally different materials.

- Tungsten is a pure metal, valued for its heat resistance.

- Tungsten Carbide is a compound of tungsten and carbon, forming a ceramic-like material. It is valued for its exceptional hardness and wear resistance, making it ideal for cutting tools and abrasives.

The Challenge of Brittleness

In its pure form, tungsten is notoriously brittle at room temperature. This makes it very difficult to machine or work with using conventional methods. Fabricating tungsten parts often requires specialized techniques like powder metallurgy.

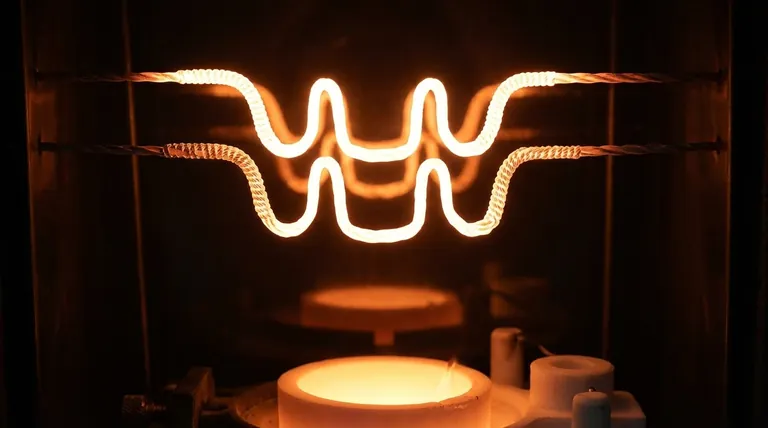

The Role of Doping

To overcome some of its brittleness and improve performance, most commercial tungsten is not perfectly pure. It is often "doped" with small amounts of other elements. This process creates non-sag tungsten wire, which is more ductile and resists drooping at extreme temperatures, a critical feature for filaments and heating coils.

Making the Right Choice for Your Application

Choosing between tungsten and its derivatives depends entirely on your primary engineering challenge.

- If your primary focus is extreme heat resistance in a vacuum or inert atmosphere: Pure or doped tungsten is the ideal choice for applications like filaments, heating elements, and furnace components.

- If your primary focus is exceptional hardness and wear resistance at ambient to moderate temperatures: Tungsten carbide is the superior material for cutting tools, abrasives, and high-wear parts.

Understanding these distinctions allows you to leverage the unique properties of the tungsten family to solve specific engineering problems effectively.

Summary Table:

| Property | Value | Key Significance |

|---|---|---|

| Melting Point | 3422°C (6192°F) | Highest of all pure metals; enables extreme heat resistance |

| Density | 19.3 g/cm³ | Contributes to high-temperature strength and stability |

| Key Application | Filaments, Heating Elements | Maintains integrity in extreme conditions |

| Limitation | Brittle at room temperature | Requires specialized fabrication techniques |

Need high-performance lab equipment for extreme temperature applications? KINTEK specializes in supplying premium lab equipment and consumables, including tungsten-based components for furnaces and high-temperature processes. Our expertise ensures you get the right materials for durability, precision, and reliability in your laboratory. Contact us today to discuss your specific needs and discover how KINTEK can support your research and production goals.

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- Why tungsten is not used in heating devices? The Critical Role of Oxidation Resistance

- Why tungsten is not used as heating element? Discover the critical role of oxidation resistance.

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments

- Can tungsten be used as a heating element? Unlocking Extreme Heat for High-Temperature Applications

- What are heating elements with tungsten? Unlock Extreme Heat for Vacuum & Industrial Processes