In manufacturing, a molding tool is a custom-made hollow block used to shape pliable raw material into a final, solid part. It functions as a negative of the desired component, allowing liquid plastic, metal, or other materials to be injected, fill the cavity, and harden into a specific, repeatable shape. This process is the cornerstone of modern mass production.

The core purpose of a molding tool is not merely to shape an object, but to enable the rapid and consistent manufacturing of thousands or millions of identical parts at an exceptionally low cost per unit.

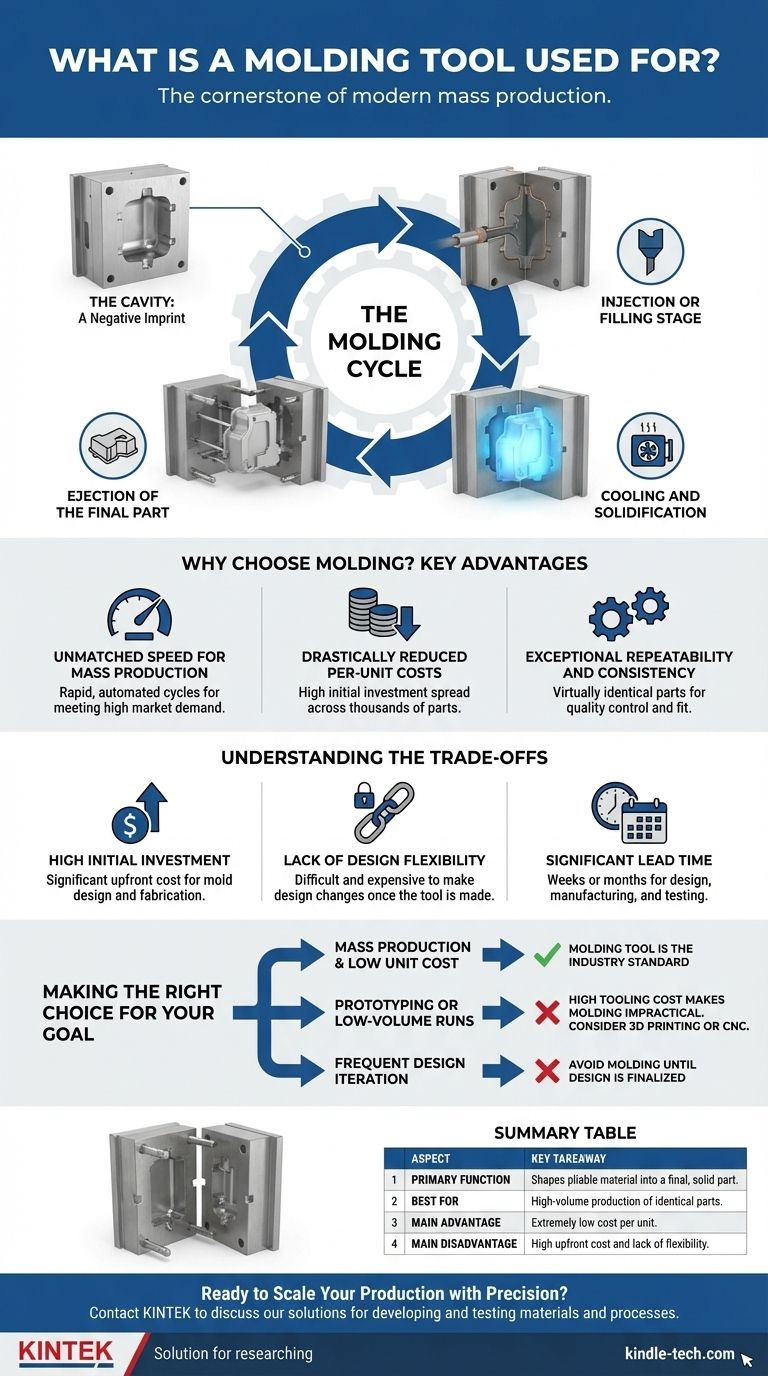

The Fundamental Principle: How Molding Works

A molding tool, often simply called a "mold," transforms a raw material into a finished product through a precise, cyclical process. It is a highly engineered piece of equipment, typically machined from hardened steel.

The Cavity: A Negative Imprint

The heart of the tool is its cavity. This is the precisely machined negative space that exactly matches the geometry of the part you want to create.

The Injection or Filling Stage

Raw material, such as molten plastic pellets, is forced into the closed tool under high pressure. This material flows into every detail of the cavity, ensuring a complete and accurate shape.

Cooling and Solidification

Once filled, the tool is cooled. This causes the raw material inside to solidify, permanently taking the shape of the cavity. This step is critical for the part's final dimensions and stability.

Ejection of the Final Part

The tool then opens, and an ejection mechanism pushes the finished, solid part out. The tool closes again, ready for the cycle to repeat, often in a matter of seconds.

Why Choose Molding? The Key Advantages

The decision to invest in a molding tool is driven by its profound impact on production speed, cost, and quality. It is the defining technology for high-volume manufacturing.

Unmatched Speed for Mass Production

Because all process steps are automated and precisely timed, molding cycles are incredibly fast. This allows for the rapid production of parts one after another, making it the ideal method for meeting high market demand.

Drastically Reduced Per-Unit Costs

While the initial cost of creating the tool is high, it is a one-time investment. When spread across thousands or millions of identical parts, the cost attributed to the tool for each individual component becomes negligible. This is how molding achieves an extremely low cost per part.

Exceptional Repeatability and Consistency

A well-made tool produces virtually identical parts with every single cycle. This high degree of precision is essential for quality control and ensuring that components fit and function correctly in final assemblies.

Understanding the Trade-offs

Despite its advantages, molding is not the right solution for every situation. Its effectiveness is tied directly to production volume.

High Initial Investment

The design and fabrication of a high-quality, hardened steel molding tool is a significant upfront expense. This investment can range from thousands to hundreds of thousands of dollars, depending on the part's complexity.

Lack of Design Flexibility

Once a tool is machined from steel, making changes to the part design is difficult, expensive, and sometimes impossible without creating a new tool. It is not suited for iterative development or products that may require frequent updates.

Significant Lead Time

The process of designing, manufacturing, and testing a molding tool can take weeks or even months. This lead time must be factored into any product development timeline.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's scale, budget, and design maturity.

- If your primary focus is mass production and low unit cost: A molding tool is the industry standard and the most efficient path to producing thousands or millions of identical parts.

- If your primary focus is prototyping or low-volume runs: The high initial tooling cost makes molding impractical; alternatives like 3D printing or CNC machining are far more suitable.

- If your primary focus is frequent design iteration: Avoid committing to a molding tool until your design is completely finalized and validated, as changes are prohibitively expensive.

Choosing the correct manufacturing method begins with understanding the fundamental trade-offs between tooling investment and per-unit cost.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Shapes pliable material into a final, solid part via a custom cavity. |

| Best For | High-volume production of thousands or millions of identical parts. |

| Main Advantage | Extremely low cost per unit after the initial tooling investment. |

| Main Disadvantage | High upfront cost and lack of design flexibility once the tool is made. |

Ready to Scale Your Production with Precision?

Choosing the right manufacturing process is critical to your project's success. If you are planning for high-volume production and require consistent, high-quality parts, a custom molding tool is the industry-proven solution.

At KINTEK, we specialize in providing the robust lab equipment and consumables necessary for developing and testing materials and processes before committing to full-scale production. Our expertise supports manufacturers in validating their designs for molding, ensuring a smooth transition to mass production.

Contact us today to discuss how our solutions can help you achieve manufacturing excellence. Let's build efficiency together.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Special Heat Press Mold for Lab Use

- Assemble Lab Cylindrical Press Mold

- Ball Press Mold for Lab

People Also Ask

- What is the role of high-purity graphite molds in vacuum hot pressing? Enhance Diamond Composite Matrix Precision

- What function do graphite molds perform during vacuum hot-pressing? Enhance Diamond/Aluminum Composite Precision

- What role does a steel pellet die play in molding BZY20 ceramics? Ensure Uniform Density & Precision.

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What is the purpose of using a mold for pellet pressing when preparing catalyst test samples? Ensure Data Consistency

- What are the core functions of high-temperature molds? Expert Insights on WC-10Co Vacuum Hot Pressing

- What is the purpose of using a hydraulic press with polished steel molds for electrode compaction? Boost Battery Performance

- What functions do High-Purity Graphite Molds perform? Enhance Your Aluminum Matrix Composite Hot-Press Sintering