In a microbiology lab, a muffle furnace is primarily used for two critical, high-temperature tasks: the complete destruction of all organic material on glassware to achieve depyrogenation, and the analytical process of ashing to determine the inorganic content of a sample. It is a specialized tool for incineration, not general-purpose sterilization.

A muffle furnace should not be confused with a standard lab oven or autoclave. Its unique purpose is to reach extremely high temperatures (often >500°C) to completely burn away organic compounds, a task that conventional heating methods cannot accomplish.

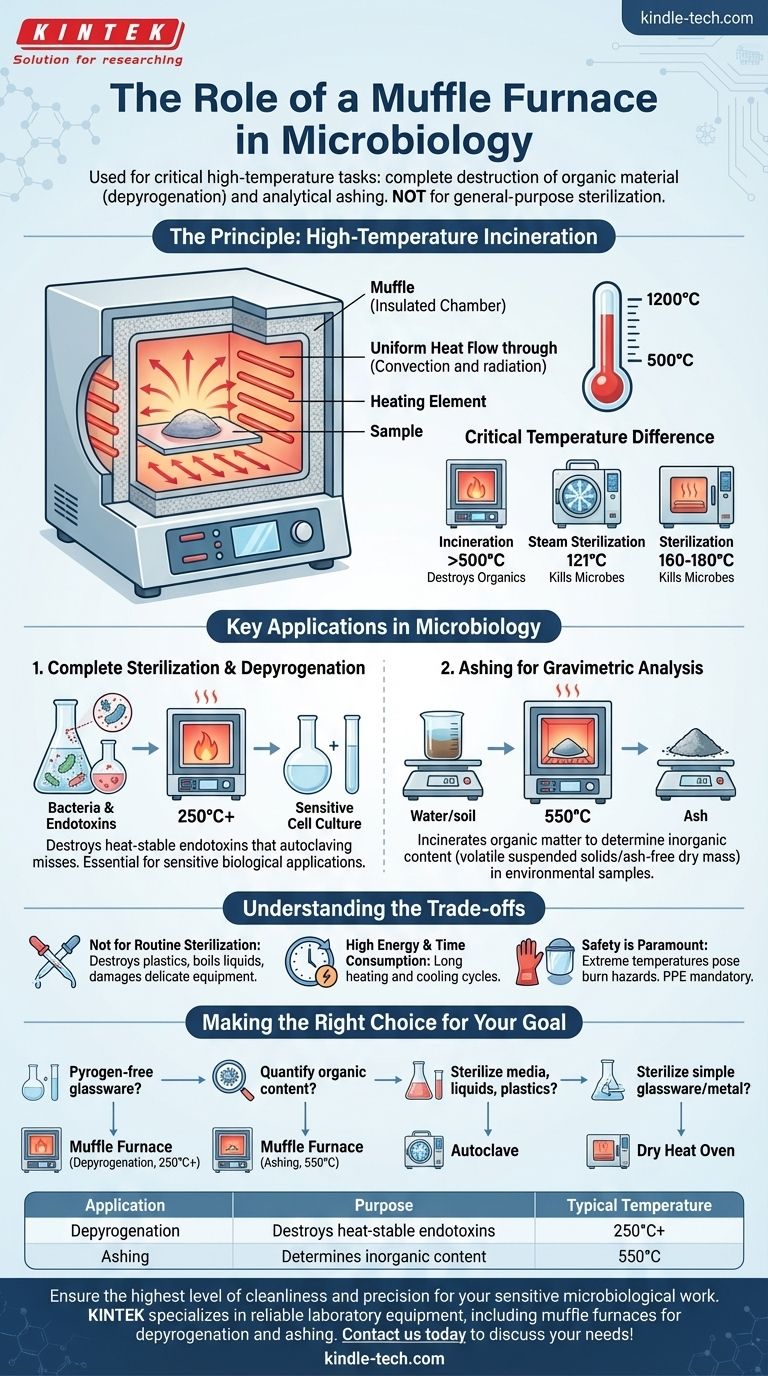

The Principle: High-Temperature Incineration

A muffle furnace is fundamentally a high-temperature oven designed for uniform, intense heating. Its name comes from the "muffle"—an insulating inner chamber that separates the contents from the direct radiation of the heating elements.

How It Works

This design ensures that the items inside are heated evenly and consistently through convection and radiation, without hot spots. This controlled environment is essential for processes that require the complete combustion of organic matter.

The Critical Temperature Difference

Standard dry heat ovens operate around 160-180°C, and autoclaves use steam at 121°C. These temperatures are sufficient to kill microorganisms. A muffle furnace, however, operates at much higher temperatures, typically between 500°C and 1200°C, to physically incinerate and remove the residual organic molecules left behind.

Key Applications in Microbiology

While its applications are niche, they are indispensable for certain types of microbiological work where the mere absence of living microbes is not enough.

Complete Sterilization and Depyrogenation

Autoclaving kills bacteria but leaves behind their heat-stable cell wall components, known as pyrogens or endotoxins. These molecules can trigger immune responses in cell cultures or animal models.

A muffle furnace operating at high temperatures (e.g., 250°C for at least 30 minutes, or higher) will completely oxidize and destroy these pyrogens, rendering glassware truly clean for the most sensitive biological applications.

Ashing for Gravimetric Analysis

In environmental microbiology, researchers often need to determine the organic content of a sample, such as water, soil, or sludge. This is referred to as measuring volatile suspended solids (VSS) or ash-free dry mass.

The procedure involves drying a sample to get its total mass, then placing it in a muffle furnace at a standardized temperature (e.g., 550°C). The furnace incinerates all organic matter, leaving only the inorganic "ash." By weighing the remaining ash, the mass of the original organic content can be calculated precisely.

Understanding the Trade-offs

Using a muffle furnace is a deliberate choice for a specific outcome, and it is the wrong tool for most common laboratory tasks.

Not for Routine Sterilization

It is extreme overkill for sterilizing culture media, plasticware, or most metal instruments. The intense heat will destroy plastics, boil away liquids, and can damage delicate equipment.

High Energy and Time Consumption

Muffle furnaces consume significant amounts of energy and require long cycles to heat up to temperature and, just as importantly, to cool down safely. This makes them highly inefficient for tasks that an autoclave can perform in minutes.

Safety is Paramount

The extreme temperatures pose a significant burn hazard. Proper training and the use of personal protective equipment (PPE), such as heat-resistant gloves and face shields, are mandatory when operating this equipment.

Making the Right Choice for Your Goal

Selecting the correct heating method is fundamental to reliable and safe lab work.

- If your primary focus is preparing pyrogen-free glassware for sensitive cell culture: Use a muffle furnace to ensure all residual endotoxins are destroyed.

- If your primary focus is quantifying the organic content of an environmental sample: Use a muffle furnace to perform ashing for an accurate gravimetric analysis.

- If your primary focus is sterilizing culture media, liquids, or plastic lab supplies: Use an autoclave, as a muffle furnace will destroy these items.

- If your primary focus is sterilizing simple, non-pyrogen-sensitive glassware or metal tools: A standard dry heat oven is a more efficient and appropriate choice.

Ultimately, a muffle furnace is an essential instrument for achieving the ultimate level of chemical and biological cleanliness required for your most sensitive work.

Summary Table:

| Application | Purpose | Typical Temperature |

|---|---|---|

| Depyrogenation | Destroys heat-stable endotoxins on glassware for sensitive cell culture. | 250°C+ |

| Ashing (Gravimetric Analysis) | Incinerates organic matter to determine inorganic content in samples. | 550°C |

Ensure the highest level of cleanliness and precision for your sensitive microbiological work. KINTEK specializes in providing reliable laboratory equipment, including muffle furnaces designed for demanding applications like depyrogenation and ashing. Let our experts help you select the right tool to enhance your lab's accuracy and efficiency.

Contact us today to discuss your specific microbiology lab needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What construction features contribute to the practicality and reliability of a muffle furnace? Key Design Elements for Lab Success

- What is the use of muffle furnace in laboratory? Essential for High-Temp Analysis & Materials Processing

- How are muffle or tube furnaces used in stainless steel creep research? Expert Insights for Precision Thermal Aging

- What events occur during sintering? From Powder to Solid in 3 Key Stages

- What Role Do High-Temperature Furnaces Play in 304L Sensitization? Achieve Precise Thermal Control for Material Research

- What is the purpose of using a high-temperature muffle furnace for analyzing sisal residue? Key Calcination Insights

- How do you use a muffle oven? A Step-by-Step Guide to Safe, Precise Operation

- What are the advantages of using a precision furnace for SrFeO3 synthesis? Low-Temp Efficiency and Nanoscale Control