In modern dentistry, a porcelain furnace is a specialized, high-temperature oven used to fabricate strong, durable, and lifelike dental restorations. These furnaces are essential for processes like firing, sintering, and glazing ceramic materials to create crowns, veneers, and bridges that precisely match a patient's natural teeth.

A porcelain furnace is not merely a heat source; it is a precision instrument that transforms powdered or pressed ceramic materials into a final, functional dental prosthesis by controlling temperature, time, and atmosphere with absolute accuracy.

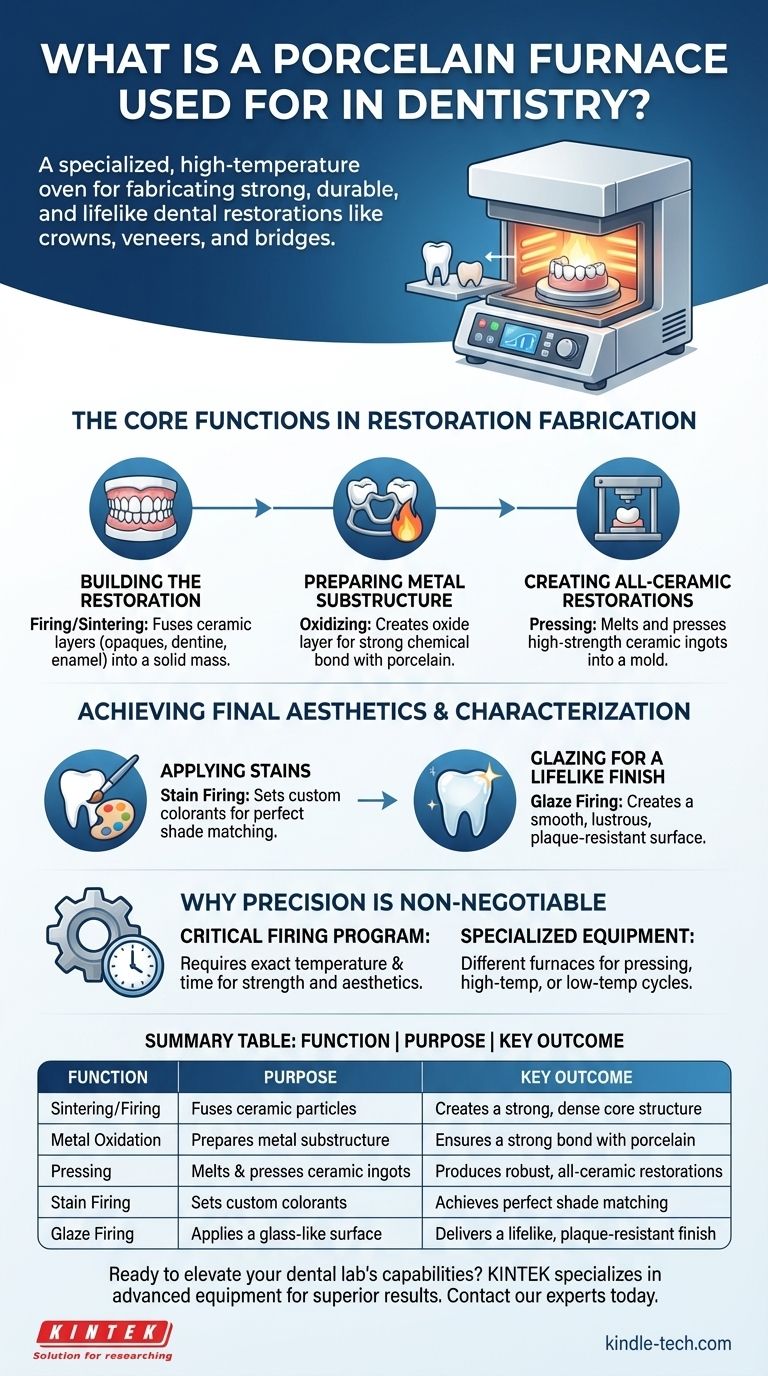

The Core Functions in Restoration Fabrication

A dental furnace performs several distinct, critical steps in the creation of both metal-ceramic and all-ceramic restorations. Each stage is vital for the final strength and appearance of the prosthesis.

Building the Restoration Layer by Layer

The primary function is firing or sintering the layers of porcelain. This process fuses the individual ceramic particles together into a solid, dense mass.

This is done sequentially for different materials, including opaques to block out the color of the underlying structure, followed by dentine and enamel materials to build up the natural shape and translucency of a tooth.

Preparing the Metal Substructure

For metal-ceramic restorations, the furnace is first used for oxidizing the metallic substructure.

This crucial step creates an oxide layer on the metal's surface, which allows for a strong chemical bond with the first layer of opaque porcelain, preventing the materials from separating.

Creating All-Ceramic Restorations

Modern furnaces, particularly pressing furnaces, are used to melt and press high-strength ceramic ingots into a mold.

These furnaces include specialized hardware to apply pressure during the heating cycle, enabling the creation of robust, metal-free restorations.

Achieving Final Aesthetics and Characterization

Once the core structure of the restoration is built, the furnace is used for the final finishing steps that give the prosthesis its natural appearance.

Applying Stains for Natural Shade

The furnace is used for stain firing, a process that permanently sets custom colorants onto the restoration's surface. This allows the dental technician to add subtle details and perfectly match the shade to the patient's adjacent teeth.

Glazing for a Lifelike Finish

The final step is glaze firing. This involves applying a thin layer of glass-like porcelain and firing it at a specific temperature.

This process creates a smooth, lustrous, and non-porous surface that mimics the light-reflecting properties of natural tooth enamel and prevents plaque accumulation.

Why Precision is Non-Negotiable

The success or failure of a dental restoration often comes down to the accuracy of the furnace. A small deviation in temperature or time can completely compromise the final product.

The Critical Role of the Firing Program

Every dental ceramic has a specific manufacturer-recommended firing schedule. Using the wrong temperature or heating rate can result in a weak, porous, or distorted restoration that is prone to fracture and aesthetic failure.

The Need for Specialized Equipment

Different procedures require different capabilities. A pressing furnace contains specialized pressing hardware not found in a standard porcelain furnace. Other furnaces may be optimized specifically for the lower-temperature cycles required for stain and glaze firing.

Matching the Furnace to the Dental Application

Choosing and using a furnace correctly depends entirely on the type of restoration being created.

- If your primary focus is metal-ceramic restorations: The furnace must excel at both high-temperature metal oxidation and the precise, repeatable cycles needed for layered porcelain.

- If your primary focus is pressable all-ceramic work: You require a dedicated pressing furnace with integrated pressure controls to properly process ceramic ingots.

- If your primary focus is final characterization: A furnace capable of accurate, low-temperature stain and glaze cycles is essential for achieving superior aesthetic results.

Ultimately, the porcelain furnace is the critical tool that transforms a technician's skill and artistry into a perfectly finished, functional restoration.

Summary Table:

| Function | Purpose | Key Outcome |

|---|---|---|

| Sintering/Firing | Fuses ceramic particles | Creates a strong, dense core structure |

| Metal Oxidation | Prepares metal substructure | Ensures a strong bond with porcelain |

| Pressing | Melts & presses ceramic ingots | Produces robust, all-ceramic restorations |

| Stain Firing | Sets custom colorants | Achieves perfect shade matching |

| Glaze Firing | Applies a glass-like surface | Delivers a lifelike, plaque-resistant finish |

Ready to elevate your dental lab's capabilities? The right porcelain furnace is the cornerstone of crafting precise, durable, and aesthetically perfect restorations. KINTEK specializes in providing dental labs with the advanced equipment and consumables needed for superior results. Contact our experts today to find the perfect furnace solution for your specific application—from metal-ceramic to all-ceramic workflows.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the strongest dental ceramic? Zirconia Leads in Strength, But Is It Right for Your Case?

- What is the function of burnout furnace? Achieve Precision Material Removal and Clean Molds

- What is ceramic dental restoration? A Guide to Modern, Aesthetic, and Durable Tooth Repair

- Why are ceramics used in implants? Unlock Superior Biocompatibility and Durability for Medical Devices

- What is the main disadvantage of dental ceramics? Balancing Aesthetics with Fracture Risk

- How does firing temperature affect ceramics? Master the Key to Perfect Strength and Aesthetics

- What is a burnout furnace? The Key to Flawless Precision Casting

- What is dental ceramic made of? Discover the Science Behind Strong, Beautiful Teeth