In essence, a thin carbon film is an extremely fine layer of carbon atoms, often just a few nanometers to micrometers thick, applied to the surface of a material. These films are engineered to lend their remarkable properties—such as extreme hardness, low friction, and electrical conductivity—to the underlying material, or substrate.

The true power of a thin carbon film lies not in the carbon itself, but in the precise control over its atomic structure, thickness, and deposition method. These factors allow a single element, carbon, to produce a vast range of films with tailored properties for specific mechanical, electronic, or chemical applications.

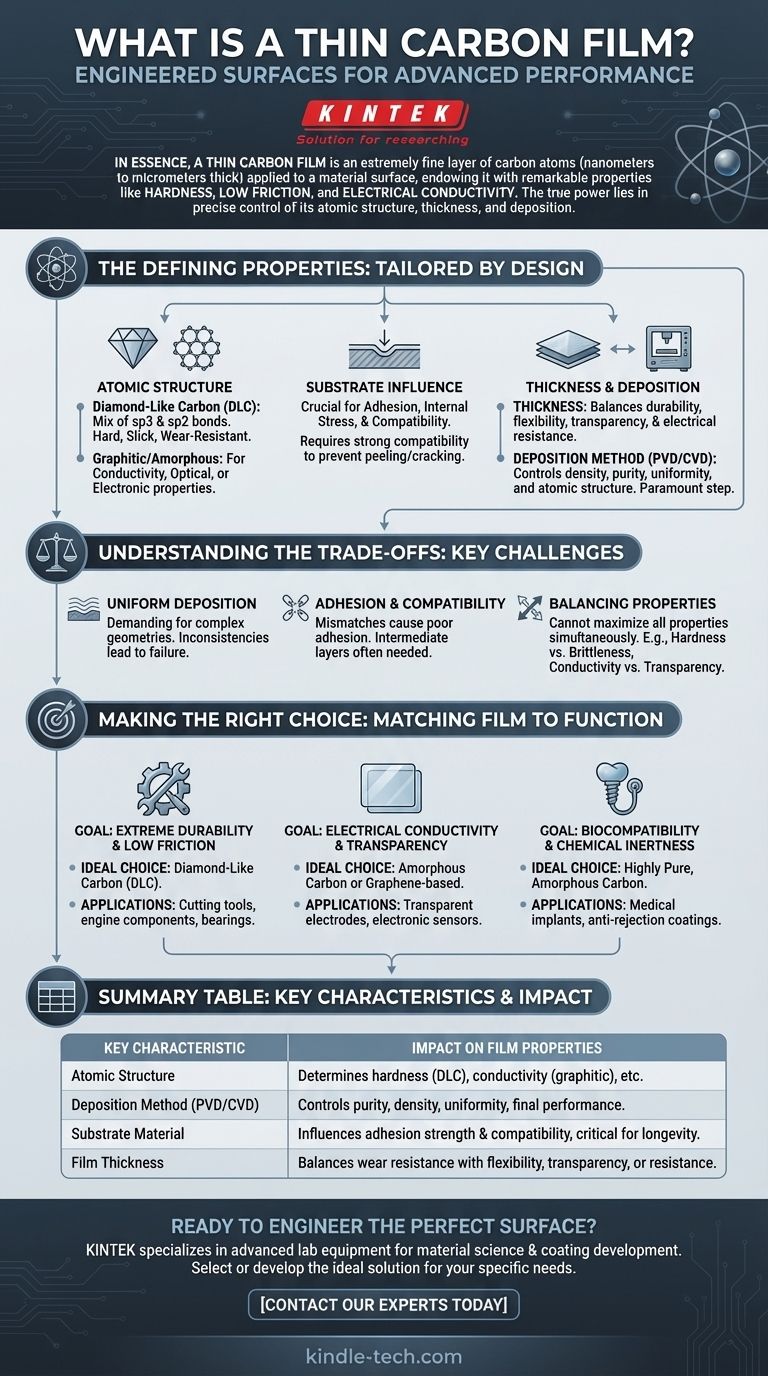

The Defining Properties of a Thin Carbon Film

The characteristics of a thin carbon film are not monolithic. They are a direct result of how the film is constructed at the atomic level and its interaction with the surface it protects.

The Role of Atomic Structure

Carbon's versatility comes from its ability to form different atomic bonds, creating materials with vastly different properties. This is most evident in thin films.

Diamond-Like Carbon (DLC) films, for example, have a mix of diamond (sp3) and graphite (sp2) bonds, creating a film that is incredibly hard, slick, and wear-resistant.

In contrast, other films might be primarily graphitic for conductivity or fully amorphous (lacking a crystalline structure) for unique optical or electronic properties.

The Influence of the Substrate

The material onto which the film is deposited plays a critical role. The substrate influences the film's adhesion, internal stress, and even its final atomic structure.

A successful coating requires strong compatibility between the film and the surface to ensure it doesn't peel, crack, or delaminate under operational stress.

The Critical Factor of Thickness

The film's thickness is a key engineering parameter. It directly impacts its mechanical durability, optical transparency, and electrical resistance.

A thicker film might offer more wear resistance but could be less flexible or transparent. The precise thickness is carefully chosen to meet the application's requirements.

How the Deposition Method Matters

The technique used to apply the film—such as Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD)—is paramount.

The deposition method controls the film's density, purity, uniformity, and atomic structure. This is arguably the most critical step in defining the film's final performance characteristics.

Understanding the Trade-offs

While powerful, thin carbon films are not a universal solution. Their application requires careful consideration of key engineering challenges.

The Challenge of Uniform Deposition

Creating a perfectly uniform film, especially over complex geometries, is technically demanding. It requires sophisticated equipment and highly controlled vacuum environments.

Any inconsistencies in thickness or structure can become points of failure, compromising the entire component.

Adhesion and Substrate Compatibility

Achieving a strong, permanent bond between the carbon film and the substrate is a significant hurdle.

Mismatches in thermal expansion or chemical incompatibility can lead to poor adhesion, rendering the coating ineffective. Often, intermediate bonding layers are required to ensure a robust connection.

Balancing Competing Properties

You often cannot maximize all desirable properties simultaneously. A film optimized for extreme hardness might be more brittle.

Similarly, increasing electrical conductivity might come at the expense of optical transparency. Engineers must balance these competing requirements based on the primary goal of the application.

Making the Right Choice for Your Goal

Selecting the correct type of carbon film is entirely dependent on the problem you need to solve. The film's properties must be precisely matched to the intended function.

- If your primary focus is extreme durability and low friction: A Diamond-Like Carbon (DLC) film is the ideal choice for protecting cutting tools, engine components, or bearings.

- If your primary focus is electrical conductivity and transparency: An amorphous carbon or graphene-based film is better suited for transparent electrodes in displays or electronic sensors.

- If your primary focus is biocompatibility and chemical inertness: A highly pure, amorphous carbon coating is necessary for medical implants to prevent rejection and wear.

Ultimately, a thin carbon film is best understood as a highly engineered surface, not just a simple layer of material.

Summary Table:

| Key Characteristic | Impact on Film Properties |

|---|---|

| Atomic Structure | Determines hardness (DLC), conductivity (graphitic), or other unique traits. |

| Deposition Method (PVD/CVD) | Controls film purity, density, uniformity, and final performance. |

| Substrate Material | Influences adhesion strength and compatibility, critical for longevity. |

| Film Thickness | Balances wear resistance with flexibility, transparency, or electrical resistance. |

Ready to engineer the perfect surface for your application?

The right thin carbon film can dramatically enhance your product's durability, performance, and functionality. KINTEK specializes in advanced lab equipment and consumables for material science and coating development. Our expertise can help you select or develop the ideal coating solution for your specific needs, whether for cutting tools, electronic components, or medical devices.

Contact our experts today to discuss how we can support your laboratory's innovation in thin film technology.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What are the steps involved in the CVD process? Master the Stages for Superior Thin Films

- How many types of CVD reactors are categorized into? Understand the Key Classifications

- What function does a Chemical Vapor Deposition (CVD) system serve? Essential Tools for High-Heat Composites

- What is the temperature range for LPCVD? A Guide to Process Parameters by Material

- What is the chemical vapor deposition process for thin film? Grow Superior, Conformal Coatings

- What is CVD production of graphene? The Industrial Process for High-Quality Graphene Sheets

- What is precursor in CVD? The Essential Guide to Chemical Source Selection