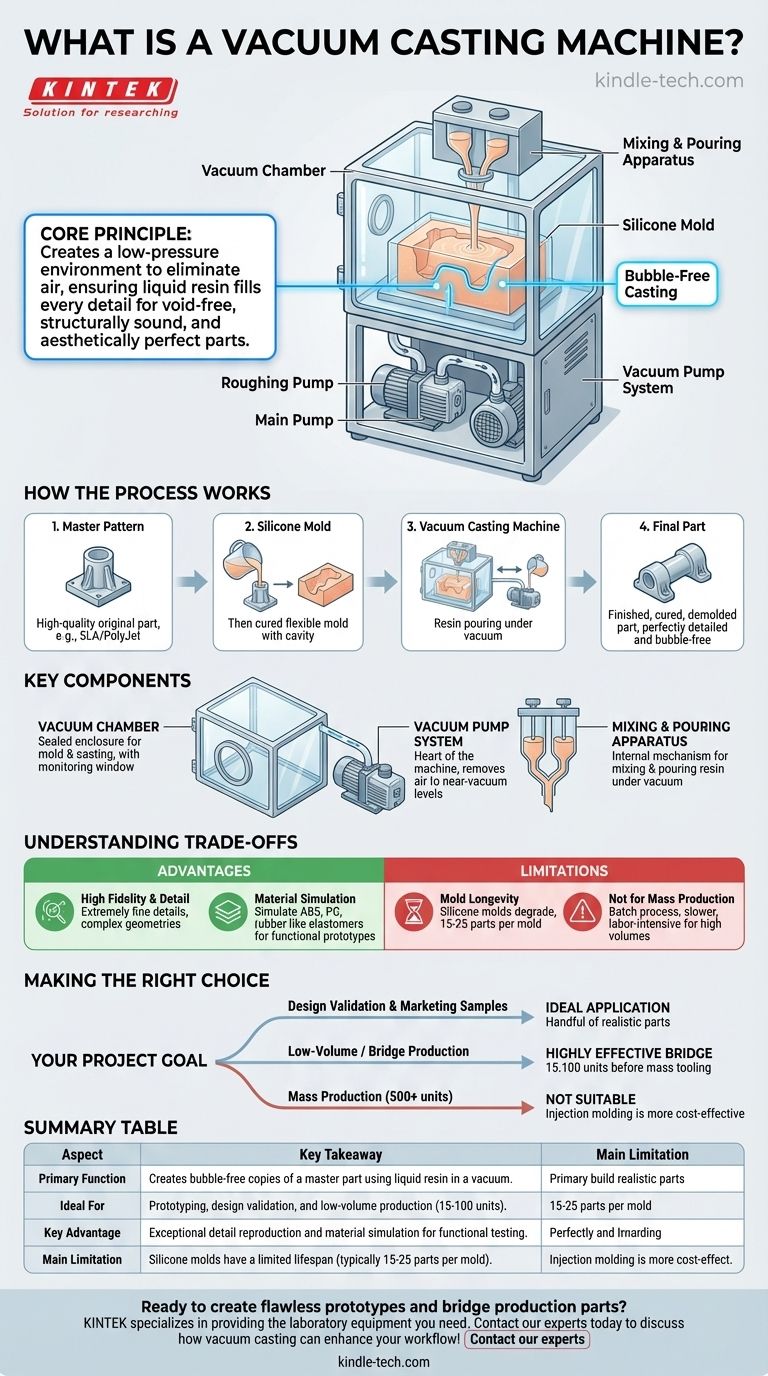

At its core, a vacuum casting machine is a specialized piece of equipment that uses a vacuum to draw liquid casting resins into a flexible mold. Its primary function is to create perfect, bubble-free copies of a master part, resulting in high-fidelity prototypes and small production runs. The machine integrates a vacuum chamber, pumps, and a pouring mechanism into a single system to control this process precisely.

The essential purpose of a vacuum casting machine is to eliminate air entrapment during the molding process. By creating a low-pressure environment, it ensures the liquid material fills every minute detail of the mold, producing void-free parts that are structurally sound and aesthetically perfect.

How the Vacuum Casting Process Works

To understand the machine, you must first understand the process it facilitates. It is a multi-step method that moves from a physical master pattern to a finished, high-quality copy.

The Master Pattern and Silicone Mold

The process begins not with the machine, but with a master pattern. This is a highly finished original part, often created using 3D printing (like SLA or PolyJet) or CNC machining.

A liquid silicone rubber is then poured around this master pattern and allowed to cure. Once solid, the mold is cut open, and the master pattern is removed, leaving a detailed, flexible cavity in its place.

The Role of the Machine

This is where the vacuum casting machine takes over. The silicone mold is placed inside the machine's vacuum chamber. The casting materials, typically two-part polyurethane resins, are also placed inside in a separate mixing cup.

The machine's vacuum pump then removes all the air from the chamber. Creating this vacuum is the most critical step, as any remaining air could become trapped in the final part.

Finally, the machine's internal mechanisms tilt the mixing cup, pouring the liquid resin into the mold. Because there is no air pressure to resist the flow, the resin is drawn deep into every feature of the mold cavity, ensuring a perfect copy. The part is then cured, often with heat, before being demolded.

Key Components of a Vacuum Casting Machine

A vacuum casting machine is an integrated system composed of several critical parts working in unison.

The Vacuum Chamber

This is the main sealed enclosure where the mold is placed and the casting occurs. It is typically made of thick steel or aluminum with a clear acrylic or glass door, allowing the operator to monitor the process.

The Vacuum Pump System

This is the heart of the machine. As the references suggest, a system may use more than one pump. A roughing pump removes the bulk of the air quickly, while a more powerful main pump (or high-vacuum pump) takes the chamber pressure down to the near-vacuum level required for a flawless cast.

The Mixing and Pouring Apparatus

This internal mechanism holds the resins. It allows the operator to mix the two components together and then pour them into the mold, all while the system remains sealed and under vacuum. This prevents air from being introduced during the pour.

Understanding the Trade-offs

While powerful, vacuum casting is a specialized process with clear advantages and limitations.

Key Advantage: High Fidelity and Detail

The primary benefit is the ability to produce parts with extremely fine detail and complex geometries without any of the voids, bubbles, or surface imperfections common in other casting methods.

Key Advantage: Material Simulation

A wide range of polyurethane resins are available, which can simulate the properties of production-grade plastics like ABS, polycarbonate (PC), and rubber-like elastomers. This makes it ideal for functional prototypes.

Limitation: Mold Longevity

Silicone molds are not permanent. They degrade with each casting cycle due to chemical and thermal stress. A single mold can typically only produce 15 to 25 parts before it needs to be replaced.

Limitation: Not for Mass Production

Vacuum casting is a batch process. It is significantly slower and more labor-intensive than high-volume manufacturing methods like injection molding. Its cost-per-part is only competitive for small quantities.

Making the Right Choice for Your Project

Use this guidance to determine if vacuum casting is the appropriate solution for your specific goal.

- If your primary focus is design validation and creating marketing samples: This is the ideal application, allowing you to produce a handful of visually and functionally realistic parts.

- If your primary focus is low-volume or bridge production (15-100 units): Vacuum casting is highly effective as a "bridge" to fill the gap before investing in expensive mass-production tooling.

- If your primary focus is mass production (500+ units): This is not the right tool; injection molding or other high-volume methods will be far more cost-effective and efficient.

By understanding its specific role in the product development lifecycle, you can leverage vacuum casting to achieve high-fidelity results with remarkable efficiency.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Creates bubble-free copies of a master part using liquid resin in a vacuum. |

| Ideal For | Prototyping, design validation, and low-volume production (15-100 units). |

| Key Advantage | Exceptional detail reproduction and material simulation for functional testing. |

| Main Limitation | Silicone molds have a limited lifespan (typically 15-25 parts per mold). |

Ready to create flawless prototypes and bridge production parts?

KINTEK specializes in providing the laboratory equipment you need to perfect your product development process. Our expertise ensures you have the right tools for high-fidelity results.

Contact our experts today to discuss how vacuum casting can enhance your workflow!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Vacuum Cold Mounting Machine for Sample Preparation

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What are the three 3 differences between compression molding and injection molding? Choose the Right Process for Your Project

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process